Danyang Kaixin Alloy Material Co., Ltd. |

|

Verified Suppliers

|

|

Product Description and Application

UNS N10276 Nickel-Molybdenum-chromium-tungsten alloy is the most resistant alloy to corrosion. Its high molybdenum composition gives the alloy local corrosion resistance and low carbon enhances stress corrosion resistance. Precipitation-age-hardened nickel-molybdenum-casew-tungsten alloy has long-term oxidation resistance, good oxidation resistance and excellent aging ductility. It is widely used in harsh corrosive environment, such as chemical industry, petroleum, flue gas desulfurization, pulp,paper environmental protection and etc industrial fields. In oxidizing and reducing environments, it has better corrosion resistance than copper in oxidizing medium, better than copper nickel in reducing medium, such as wet chlorine resistance, various oxidizing chlorides, chloride solution, sulfuric acid and chlorinated salt and hydrochloric acid widely used in low temperature and middle temperature.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| Ni | Cr | Fe | C | Mn | Si | Mo | W | Co | V | P | S | |

| Min | 15 | 4 | 15 | 3 | 0.1 | |||||||

| Max | Rem | 16.5 | 7 | 0.01 | 1 | 0.08 | 17 | 4.5 | 2.5 | 0.3 | 0.015 | 0.01 |

| Density | ρ=8.9g/cm3 |

| Melting Temperature Range | 1325~1370℃ |

The UNS N10276 is suitable for welding by any traditional welding process, such as tungsten electrode inert gas welding, plasma arc welding, manual subarc welding, metal inert gas welding or molten inert gas welding.

Productive Process

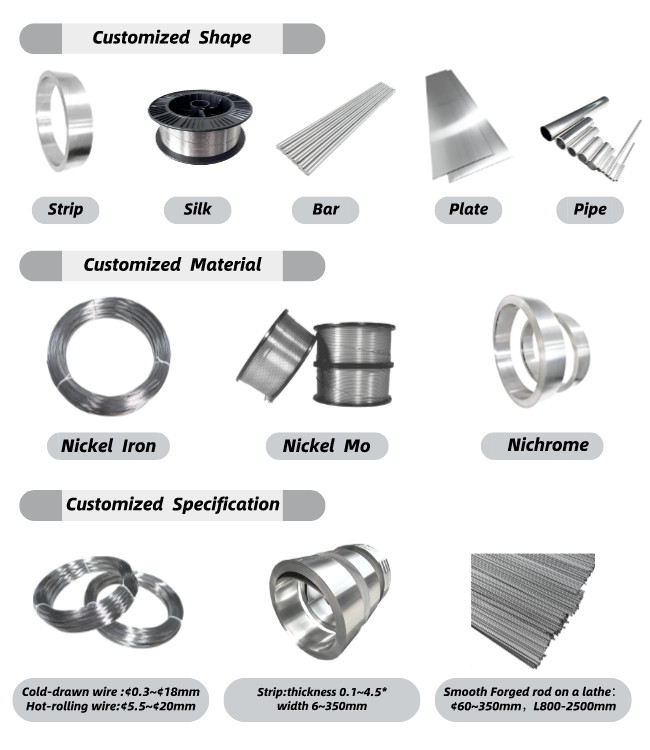

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |