Danyang Kaixin Alloy Material Co., Ltd. |

|

Verified Suppliers

|

|

Product Description and Application

NiCr19Fe19Nb5 is also known as UNS NO7718,UNS N07718, W.N.2.4668,GH4169 (China), Inconel 718

NiCr19Fe19Nb5 is a Ni-Cr-Fe base precipitation-hardening deformed superalloy with a long-term operating temperature range of -253℃~650℃ and a short-term operating temperature of 800℃. The alloy has high strength below 650℃ and has good fatigue resistance, radiation resistance, oxidation resistance and corrosion resistance, as well as good processability, weldability and long-term structural stability. Suitable for the manufacture of turbine discs, rings, blades, shafts, fasteners and elastic components, plate structural parts, casing and so on in aviation, aerospace, nuclear energy and petrochemical industries. Alloy composition is divided into ordinary and high quality, high-quality NiCr19Fe19Nb5 alloy carbon, niobium, sulfur and gas content control is more strict, mainly used for manufacturing all kinds of rotating parts.

Process Performance and Requirements

Vacuum Induction Furnace(VIM) and Electroslag Remelting Furnace(ESR)

| Alloy | % | Ni | Cr | Fe | Mo | Ni | Co | C | Mn | Si | S | Cu | Al | Ti |

| NiCr19Fe19Nb5 | Min | 50 | 17 | Rem | 2.8 | 4.75 | 0.20 | 0.65 | ||||||

| Max | 55 | 21 | 3.3 | 5.50 | 1.0 | 0.08 | 0.35 | 0.35 | 0.015 | 0.30 | 0.80 | 1.15 |

| Density | 8.24g/cm3 |

| Melting Point | 1260-1320℃ |

| Magnetic Energy | Nil |

| Variety and Specification | Heat Treatment | Tensile Property | Hardness | Durability | |||||

| MPa | MPa | % | MPa | r/h | % | ||||

Plate Sheet Strip | --- | Anneal | ≤895 | ≤485 | ≥40 | HRB≤ 94 | --- | --- | --- |

| ≤ 0.25 | Solid Solution | ≤965 | ≤550 | MV | HRB≤ 102 | --- | --- | --- | |

| > 0.25~4.75 | ≤965 | ≤550 | ≥30 | HRB≤ 102 | --- | --- | --- | ||

| >4.75~25 | ≤1035 | ≤725 | ≥30 | HRC≤ 25 | --- | --- | --- | ||

| ≤ 0.25 | Standard Heat Treatment | ≥1240 | ≥1035 | MV | HRC≤ 36 | --- | --- | --- | |

| >0.25~25 | ≥1240 | ≥1035 | ≥12 | HRC≤ 36 | --- | --- | --- | ||

| ≤ 0.38 | ≥965 | ≥795 | ≥5 | --- | 655 | ≥23 | --- | ||

| > 0.38~0.62 | ≥965 | ≥795 | ≥5 | --- | 655 | ≥23 | 4 | ||

| > 0.62~25 | ≥1000 | ≥825 | ≥5 | --- | 690 | ≥23 | 4 | ||

| Standard Number | Variety | Heat Treatment | ℃ | Tensile Property | ||

| MPa | MPa | % | ||||

| Q/3B 4052 | Capillary Tube | Solid Solution | 20 | ≤ 1070 | ≤ 655 | ≥ 30 |

| Standard Heat Treatment | 20 | ≥ 1275 | ≥ 1035 | ≥ 12 | ||

| Remark: The whole tube tensile specimen is used | ||||||

| Standard Number | Variety | Heat Treatment | ℃ | Tensile Property | Hardness | Durability | |||||

| MPa | MPa | % | % | MPa | r/h | % | |||||

| GJB 2611A | Cold Drawn Rod | Standard Heat Treatment | 20 | ≥ 1270 | ≥ 1030 | ≥ 12 | ≥ 15 | HBW≥ 345 | --- | --- | --- |

| 650 | ≥ 1000 | ≥ 860 | ≥ 12 | ≥ 18 | --- | 690 | ≥ 23 | ≥ 4 | |||

| GJB 3527 | Cold Drawn Wire for Springs | 20 | ≥ 1270 | ≥ 1035 | ≥ 12 | -- | HBC≥ 32 | --- | --- | --- | |

Product Heat Treatment Institution

Wire

955℃±10℃x1h/AC+720℃士10℃x8h/FC(50℃士10℃/h)→620℃±5℃×(7`8)h/ AC,HRC≥32;

Rods and forgings,

(950~980)℃士10℃x1h/AC+720℃±5℃x8h/FC(50℃士10℃/h)→620℃±5℃ x8h/AC,HB≥346;

Plate and welding parts

Institution I:(940~960)℃/AC+(710~730)℃x(8~8.5)h/FC(50℃±10℃/h)→(615~620)℃x(8~8.5)h/AC,Solid Solution Holding time:(d)≤3mm,(25~30)min;(d)3mm~5mm,(30~35)min;

Tube

955℃士10℃x30min/AC(or air cooled)+720℃±10℃x8h/FC(50℃±10℃/h)→620℃±10℃.Make the total holding time not less than 18h, air cooled or forced air cooled

Direct aging treatment for Disc forgings:720℃士10℃x8h/FC(50℃±10℃/h)→620℃±10℃x8h/AC

Direct Aging Treatment

Direct aging treatment for Disc forgings:720℃士10℃x8h/FC(50℃±10℃/h)→620℃±10℃x8h/AC

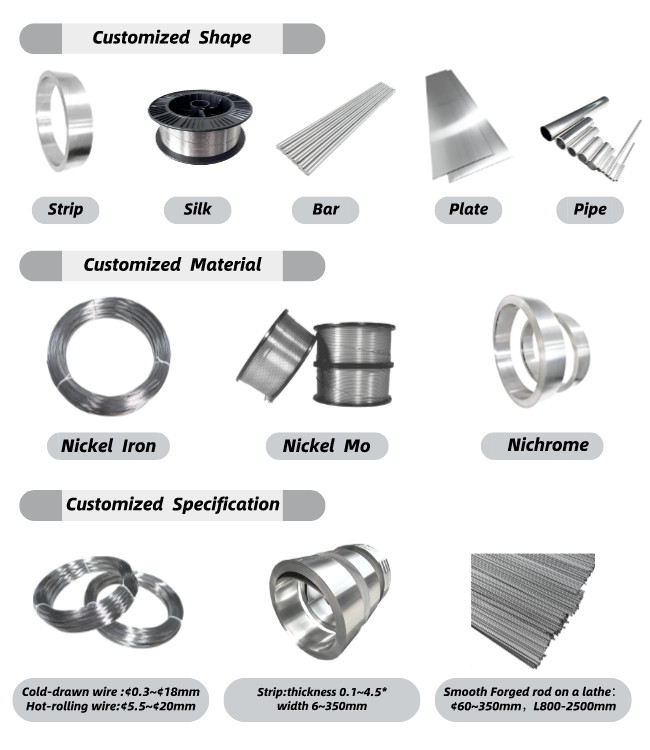

Professional Customization

| Cold-drawn Wire | ¢0.3~¢18mm(Delivery in rolls or trays) |

| Hot-Rolling Wire | ¢5.5~¢20mm(Delivery in rolls) |

| Strip | thickness 0.1~4.5*width 6~350mm(Supply in rolls or straight strips) |

| Smooth Forged Rod on a Lathe | ¢60~350mm,L800-2500mm |

| Hot-rolled Burnishing | ¢20~80mm,L1000-5000mm |

| Cold Drawn and Burnishing | ¢2.5~18mm,L1000-8000mm |

| Seamless Tube | ¢1~275mm,wall thickness 0.2~30,L1000-8000mm |