Shenzhen Onetop Technology Co.,Ltd |

|

Vertical Injecting Molding Machine, Plastic Making Machine Injection Molding Machine Factory

Product features

1. Single-station low-pressure injection molding machine adopts

single-station top-type glue injection system. The models designed

for a variety of different injection-molded encapsulation products,

especially the design of the left and right parallel connection

wire outlet molds are more reasonable and reliable.

2. The operating table and the sol system adopt a split layout,

which is flexible to use. The glue injection gun is connected with

the glue tank through the hose; the structure is compact and the

performance is stable.

3. The clamping adopts gas-liquid pressurized cylinder, which has

greater clamping force, which is suitable for mass production of

products with large injection area and large injection volume.

5. Single station low pressure injection molding machine, computer

touch screen man-machine interface, real-time monitoring and

simulation display man-machine control system. The injection

pressure is adjustable, and the DELTA temperature control module

can accurately monitor the temperature.

6. The two-hand switch mold clamping, safety grating, and emergency

stop switch ensure safe operation.

7. The mold is easy to replace, and the product ejection device is

built in the workbench to facilitate the removal of the product.

8. The machine is designed according to the ergonomic footboard,

which is convenient for production and operation.

| Model | JTT-100 | ||

| Injection system | cylinder Diameter/length | mm | Φ8*1600 |

| Injection Pressure | kg/cm2 | 1.5-4 | |

| Max shot weight | g | 100 | |

| Nozzle Stroke | mm | 50 | |

| Number of Temperature Control | - | 1+2 | |

| Hopper Capacity | L | 6 | |

| Clamping system | Clamping Force | tons | 1 |

| Opening Force | tons | 0.4 | |

| Platen Size | mm | 220*330 | |

| Distance Between Tie Bar | mm | 390 | |

| Min Mold Height | mm | 20 | |

| Opening Stroke | mm | 150 | |

| Max Open Daylight | mm | 200 | |

| Ejector Force | tons | 0.1 | |

| Ejector Stroke | mm | 10 | |

| Air pressure electric system | Into the main pressure | kgf/cm2 | 5-7 |

| Voltage | V | 220 | |

| Motor power | kw | 0.4 | |

| Total Power | kw | 3.4 | |

| Working power | KW | 0.8 | |

| Other | Machine Weight | tons | 0.5 |

| Machine Dimension | m | 0.8*0.75*1.67 |

Selling point

Improve product quality

1. Low injection pressure, no damage to components, low product

defect rate

2. Powerful protection function, sealing/waterproof/temperature

resistance/buffer shock/electrical insulation, etc.

3. Environmentally friendly high-quality materials, in line with

the EU ROHS directive, the nozzle material can be reused

Improve product production efficiency

1. Rapid curing molding: 2-50S

2. Short mold development cycle: 1-5 days

Save total production cost

1. Low cost of injection molding equipment

2. Low mold cost

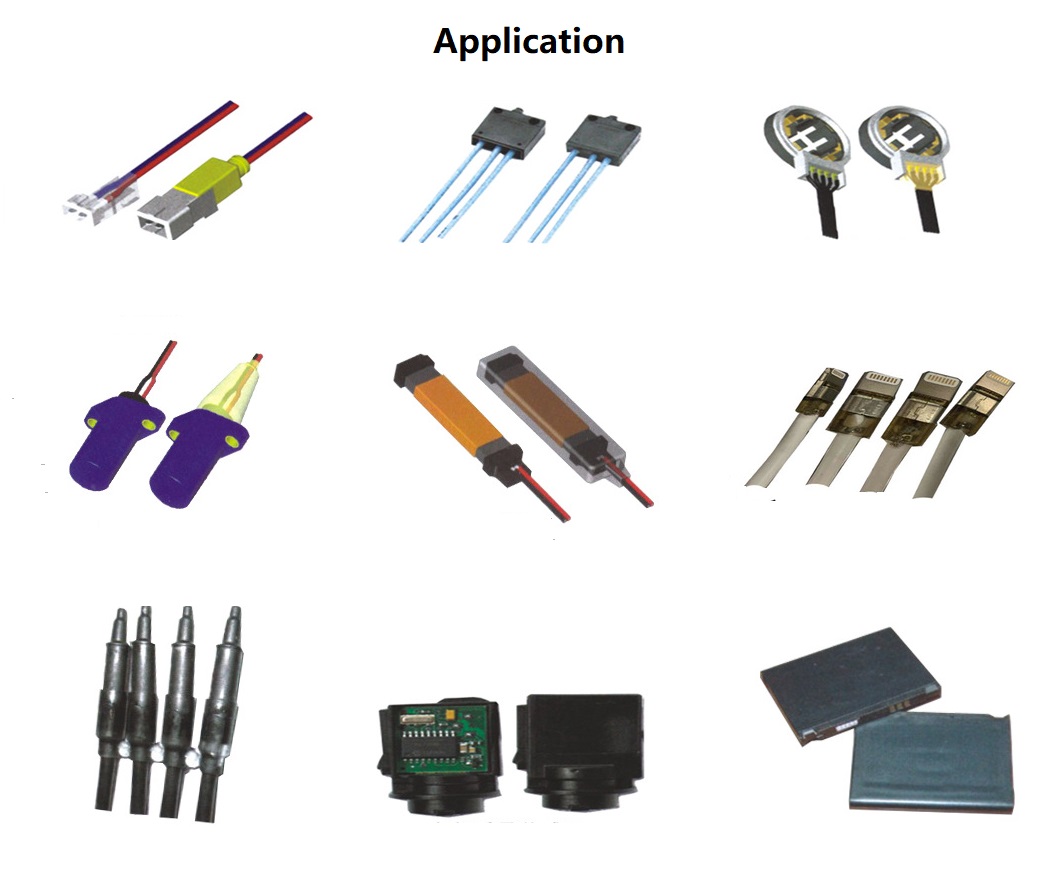

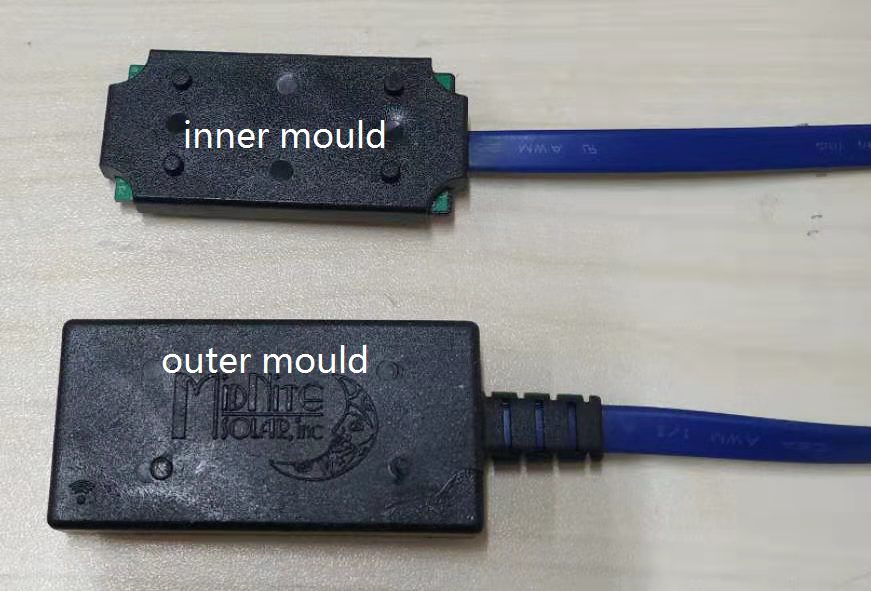

Appllication

It's widely apply to produce various terminal blocks, electronic component, USB data cable, connectors, cables, sensor,microswitch,mobile phone plug,etc.The complete package can play a role in waterproofing and protecting precision electronic components

Customer cases

Company Information

Shenzhen Onetop Technology Co Ltd , is a manufacturer which combines R&D and marketing ,we have professional R&D team as well as proficient stuff ,and has been specializing in researching and producing high quality lithium battery machine for 10 years . Our main products ranges from 18650 battery pack assembly machine ,Power Battery PACK assembly machines ,Power Bank Assembly machine,Mobile Phone Battery assembly Machines,Battery safety test equipment,Injection molding machine,Molds, Molding materials, machine parts, etc

We keep in place with the word ,we adopt lastest technology and design ,our Onetop series battery machine stands out in the same industry area ,they are of national advanced technologycal level and have been identified by experts from Shenzhen Science & Technology and Information Bureau .Up to now ,we have obtained many inventions patents ,practical new patents ,and own independent intellectual property rights

.

With the increasing development ,We have created two workshops to

manufacture battery machines and injection molding machines

Through our efforts, the Automatic Battery PACK Assembly machines

are now widely used in Mobile phone,Power bank,Laptop,Electric

bikes,Electric vehicle,solar street lights,Solar energy

storage,Banks,LED devices,Health Equipments ect,the low-pressure

injection molding machines are now widely used in PCBs, sensor

products, wiring harnesses, medical electronic products, etc. In

addition, OEM/ODM services can be provided to customers worldwide.

Our products enjoy high quality and guarantee all-weather

after-sales service, thus winning our 70% market share.we look

forward to cooperation with the customers all over the world .

Contact us

Ms.Tina (Sales manager)

Cel/Wechat/whatsapp:+86-13543252590

Email: admin@onetop-tech.com

Add:No.410,Donghuan road,Shajing,Bao'an district,Shenzhen,China