Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd |

|

Verified Suppliers

|

|

4000 Bph Pump Cap Capping Machine For Plastic Bottle Auto Capping Machine

Introduction of pump cap automatic capping machine

The machine integrates bottle inlet, cap feeding,screwing and bottle outlet. It uses the cap grab and positioning capping. The whole machine is rotary structure, suitable for the capping of pump cap and sprayer cap. In the process of capping, there is no bottle damage,cap damage phenomenon, high efficiency of capping, high qualified rate, stable operation and wide range of use.

Parameters of pump cap automatic capping machine

| 1 | Capacity | ≤4000 bottles/hour |

| 2 | Suitable bottle size | Customized according to the bottle type of customers |

| 3 | Cap size | Customized according to caps |

| 4 | Air pressure | 0.5-0.7 Mpa |

| 5 | Power | ~380V 50Hz/4KW |

| 6 | Machine weight | Around 4500Kg |

| 7 | Machine size | 2200×1600×2600mm(L×W×H) |

Features of pump cap automatic capping machine

1 High qualified rate: the qualified rate of screw cap is close to 100%. The magnetic torque can effectively control the torque range, prevent damage to the bottle and cap, and improve the qualified rate of screw cap.

2 The whole machine uses the customized electrical control system of Schneider Electric, which is more stable, reliable, safe, green and low energy consumption.

Explosion proof configurations of pump cap automatic capping machine

1 The explosion proof cabinet includes: PLC, touch screen, frequency converter, switching power supply and other components.

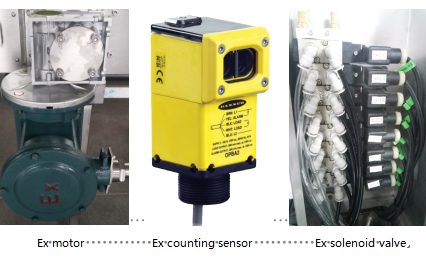

2 Explosion proof equipment includes: explosion-proof motor, explosion-proof photoelectric, explosion-proof solenoid valve, explosion-proof junction box, explosion-proof threading tube.