Jiangsu Join Industrial Co., Ltd. |

|

Verified Suppliers

|

|

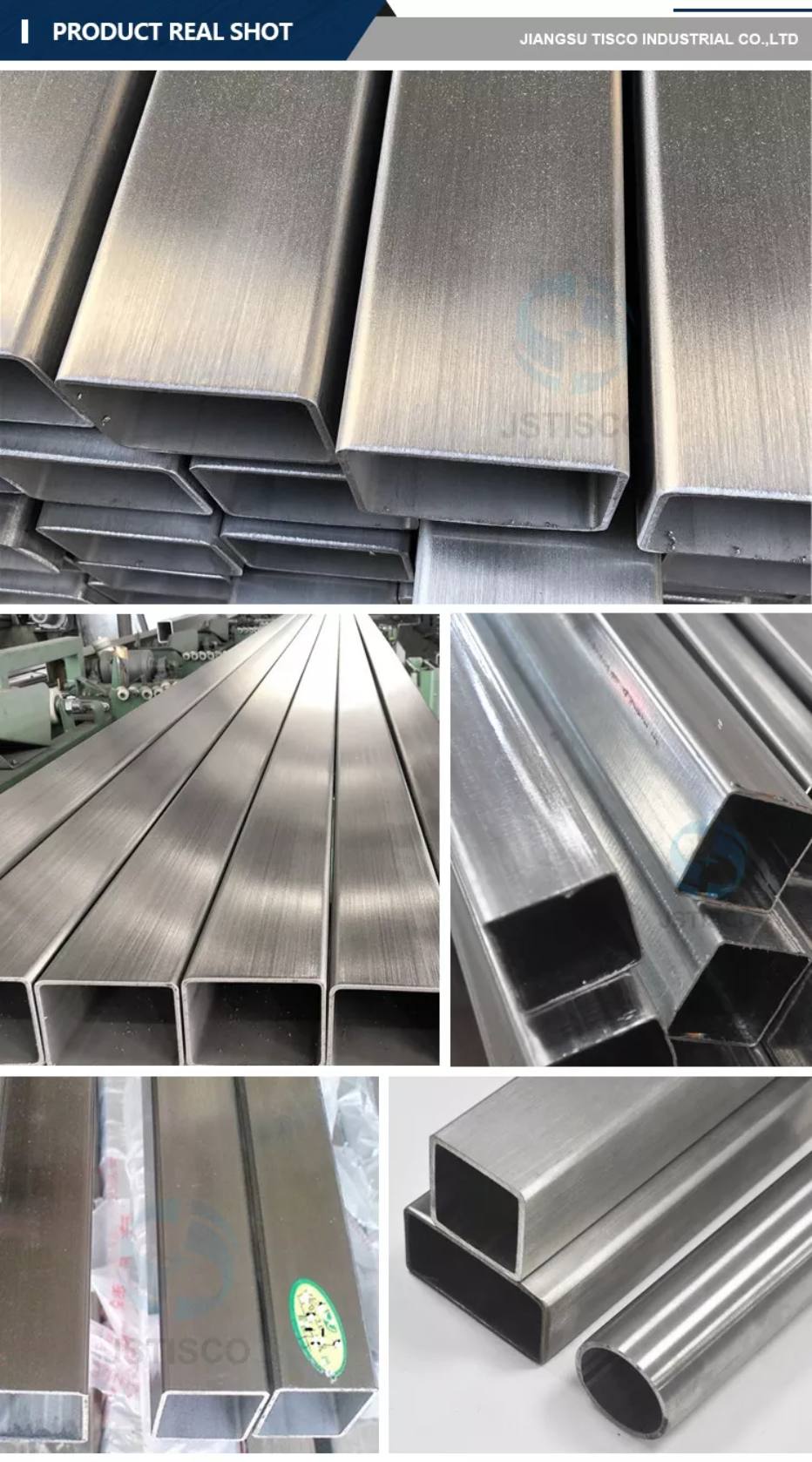

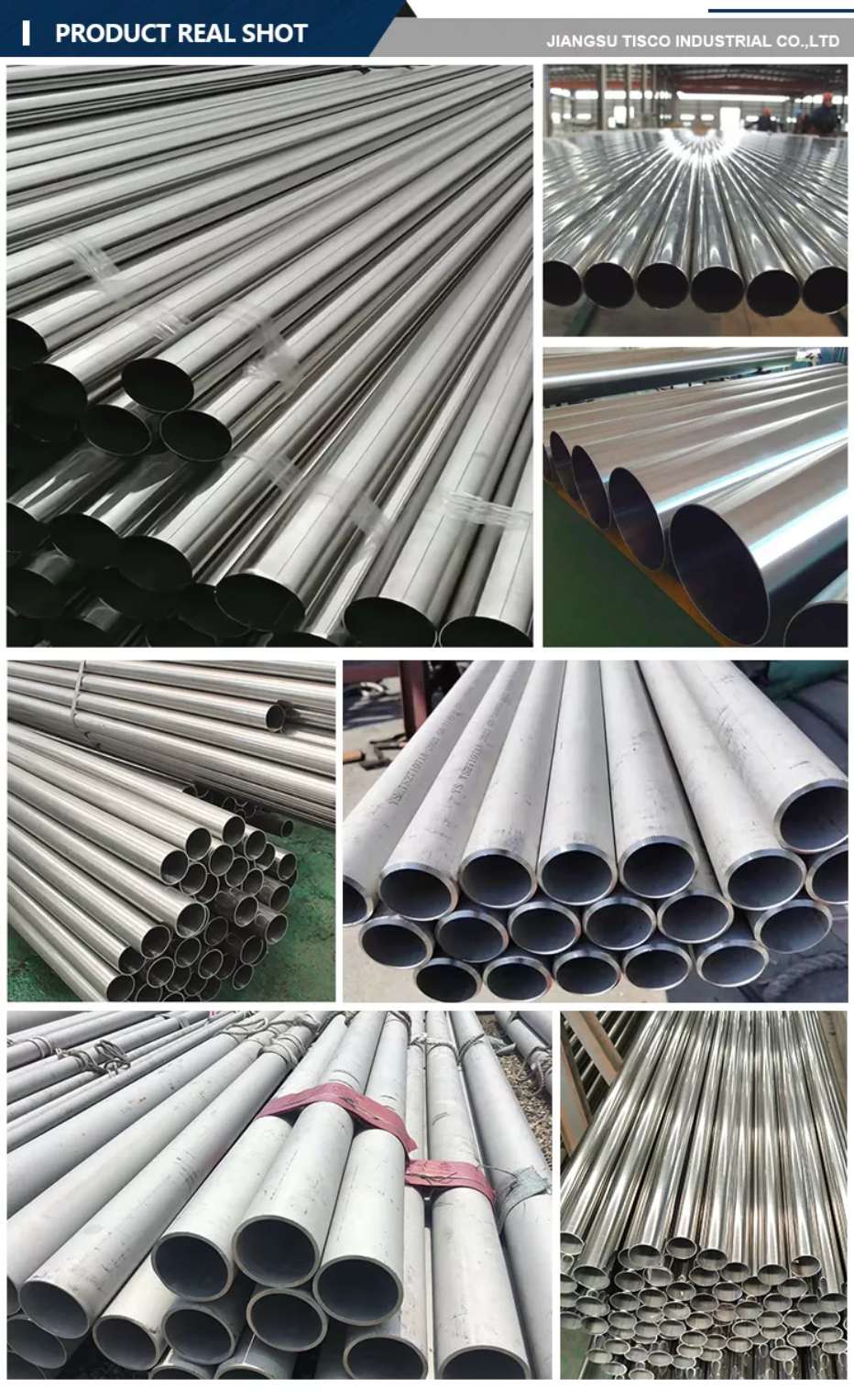

Square Stainless Steel Seamless Pipe

Square tubes are formed from coils and then ran through a series of dies. They are are welded from the inside to form their shape. Square tubes are generally used for maintenance and structural purposes. Some examples of applications would be building construction, railings, and sign posts. They are measured by their outside dimensions and their wall thickness.

1. The de-fire operation is followed by a multi-pass cold drawing (cold rolling) process. The cold rolling of seamless pipes is carried out on a multi-roll mill. The stainless steel seamless pipe is rolled with a circular pass composed of a variable-section circular groove and a fixed cone head.

2. The stainless steel tube after cold rolling has the advantages of a large yield coefficient, no expansion, bending, and so on. In order to meet the health grade standard of stainless steel seamless pipe, the cold-rolled pipe should be subjected to bright defire, demagnetization, pickling, straightening, and other steps.

3. Pickling stainless steel pipe, when the pipe is removed from the oil, rust, spot welding, an oxide layer, free iron, and other dirt, the surface becomes silver treated, and then the surface is uniformly pickled and passivated to prevent it from passing through Corrosion and hydrogen embrittlement of metals inhibit the production of acid mist.

4. After the above process, the next step is the polishing process of the stainless steel tube. The inner and outer walls of the pipeline are polished to a standard of 400 mesh, and the inner and outer surfaces of the pipeline are polished to a mirror surface standard (ie, hygienic standard).

5. The polished stainless steel seamless pipe should undergo internal flaw detection and strict manual selection by the steel pipe quality inspector through a metal flaw detector (or hydrostatic test), and qualified products should be packaged and delivered.

Production process: 1. Steel making → 2. Rolling round bar (peeling) → 3. Piercing (retarding) → 4. Cold drawing → 5. Cold rolling (retarding, demagnetization, pickling, cleaning) → 6. Inner wall polishing (400 mesh)→7.Exterior wall polishing (400 mesh)→8.Air pressure test→9.Surface test→10.Attach trademark and certificate of conformity×11. Packaging → 12. Delivery.Square Tube is commonly available in Aluminum, Stainless Steel, Hot Rolled Steel and Cold Rolled Steel.