Shenzhen Joaboa Technology Co., Ltd |

|

Verified Suppliers

|

|

Bondsure™ Membrane Series

Bondsure® S-CLF Super Cross Laminated Film Self Adhesive Waterproofing Membrane is a kind of bituminous waterproofing products composed of imported super cross-laminated film, self-adhesive rubber asphalt adhesive material with high performance formula, anti-adhesive layer & isolation film, with stronger tensile strength, elongation and tear resistance, and has excellent UV resistance and stability.

Types:

1) Pre-applied Type: YC Type(Pre-laid with sand surface)

2) Self-adhesive Type: NS Type(Single Side Self-adhesive), ND Type(Double Side Self-adhesive)

For this article, we only talk about NS Type and ND Type.

Please refer to S-CLF II Super Tensile Strength Pre-applied Waterproof Membrane (Code: CHINA RED) for more information about YC Type of S-CLF Membrane.

1. Excellent Physical Properties

It has excellent physical properties and high tensile properties, which is 2~3 times of that of the traditional non-tire self-adhesive coils,

2. High Thermal Stability

Excellent thermal stability, grayish white surface, can effectively reflect light.

3. Excellent Elongation & Dimensional Stability

Composed of super cross laminated film imported from Valeron, with good dimensional stability, can effectively reduce the fold, warping and other conditions; with excellent elongation, can adapt to the deformation of the base.

4. Strong Bonding Strength

The membrane can be bonded tightly to the substrate, if there is local failure on the membrane, water would be confined in a limited area without fluid-channeling, which makes it much easier to repair.

5. Simple Construction Method

Under the same physical performance conditions, the coil is lighter and thinner. Thus, more convenient and faster for the application.

6. Skin-type Waterproofing

For Pre-applied S-CLF Membrane, the upper surface is an anti-sticking layer, which can effectively prevent workers from sticking feet and has a certain puncture resistance effect. In the construction of the basement floor, it can be reverse bonded with the post-cast concrete to achieve the "skin type" waterproof effect, and the bond is firm, even still inseparable with the concrete after long-term immersion.

※ Scope of Application

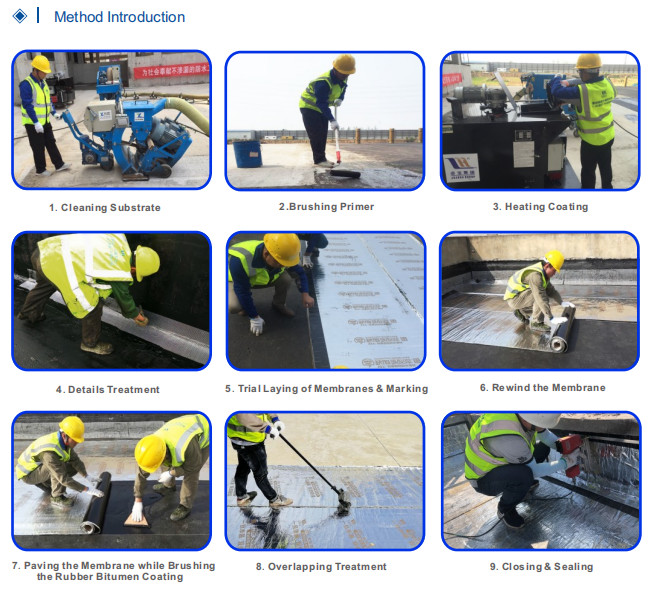

S-CLF Super Tensile Strength Self Adhesive Waterproof Membrane (NS & ND Type) can use construction methods as below: Wet Application, Hot Application, Dry Application.

1. Wet Application

2. Hot Application

3. Dry Application

※ Storage and Transport

1. Different types or specifications of products should be separated, not mixed.

2. Keep it dry and ventilated, protected from the sun or rain.

3. Storage temperature should not be higher than 45 ℃. Pile up the membranes flatwise whose stockpile height should not exceed five layers.

4. Prevent tilt or side pressure during transportation, and cover with felt if necessary.

5. Storage time is at least one year from manufacture date if the product is under normal storage condition.

※ International & Domestic Certificate

ASTM Testing Report of Bondsure® S-CLF Super Tensile Strength Self Adhesive Waterproofing Membrane (NS Type)

S-CLF has been approved by the Evaluation Committee of Science and Technology Development Promotion Center of Ministry of Housing and Urban-Rural Construction.

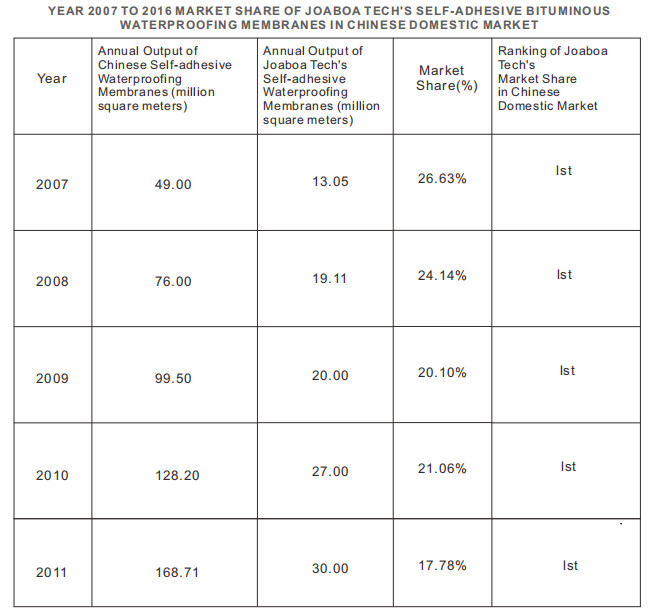

※ Market Share

Joaboa Tech, Inventor and Representative Brand of Chinese Self-adhesive Waterproof Membrane, whose market share has ranked as Top 1 in Chinese domestic market for over 10 years, widely used in Viet Nam, Cambodia, India, etc. as well.

※ Document Download