CHIFON ELECTRIC CO.,LIMITED |

|

Product Specification

| Basic Function | Specification | |

| Maximum output frequency | 0~500Hz | |

| Carrier frequency | 0.5kHz~16.0kHz;According to the load characteristics, carrier frequency can be adjusted automatically | |

| Input frequency | Range :47~63Hz | |

| Control mode | V/F Open/closed loop vector control(SVC/FVC) | |

| Speed range | 1:50(Vector mode 0 ) 1Hz/150% rated torque | |

| Overload capability | G type:150% rated current for 60s; 180% rated current for 3s 150% rated current for 3s | |

| Torque boost | Auto Torque boost Manual Torque boost; 0.1%~30.0%. | |

| V/F curve V/F | Four modes : Line , Multi-point , Square V/F curve, V/F separation | |

| Jog control | Jog frequency range:0.00Hz to F0-10(Max frequency) | |

| Accelerate/Decelerate curve | Line or S-curve Acc/Dec mode, four kinds of Acc/Dec time Range of Acc/Dec Time0.0~65000.00s. | |

| DC brake | DC brake frequency: 0.00Hz to Maximum frequency brake time: 0.0 to 36.0s brake current value: 0.0 to 100% | |

| Simple PLC, Multi-speed | 16-speed operating through built-in PLC or control terminal | |

| Built-in PID | Close loop control system can be formed easily by using PID | |

| Automatic voltage regulating (AVR) | Output voltage is regulated when voltage of the power network changes | |

| Overvoltage and over current stall control | During operation automatically limits the inverter output current and bus voltage, to prevent fan over current and overvoltage trip. | |

| Rapid current limiting function | Minimizing flow failures, protect the normal operation of the inverter | |

| Instantaneous stop non-stop | Load feedback energy compensation voltage is reduced and continues to maintain a short time when change is momentarily interrupted. | |

| Speed tracking start | For high-speed rotation of the motor speed identification, impact- free smooth start | |

| Rapid current limit | Rapid software and hardware limiting technology to avoid frequent converter over current fault. | |

| Virtual IO | Five sets of virtual DO, five sets of virtual DI, enables easy logic control. | |

| Timing Control | Timing control: set the time range 0.0Min~6500.0Hour | |

| Multi-motor switch | Two independent motor parameters, enabling two motors switching control | |

| Bus Support | Two independent Modbus communication, CAN-Link | |

| Command source | Given the control panel, control terminal, serial communication

port given. It can be switched by a variety of ways. | |

| Torque boost | Auto Torque boost Manual Torque boost ; 0.1%~30.0%. | |

| Frequency source | Nine kinds of frequency sources: digital setting, analog voltage setting, analog current setting, pulse setting, or serial port and so on. It can be switched by a variety of ways. | |

| Auxiliary frequency source | Nine kinds of auxiliary frequency source. Flexible implementation

of auxiliary frequency tuning, frequency synthesis. | |

| Input terminal | Six digital input terminals, one only supports 50khz high pulse

input Two analog input terminals, one support 0V~10V voltage input One support 0 ~ 10V voltage input or 0 ~ 20mA current input | |

| Output terminal | One high-speed pulse output terminal (optional open collector

type), support of square wave 0 ~ 50kHz signal output One digital output terminal One relay output terminals Two analog output terminals, support 0 ~ 20mA current output or 0 ~ 10V voltage output | |

| Display and operation | ||

| LED display | Display parameters and status information | |

The key lock and function selection

| Achieve some or all of the keys locked, scope definition section

keys to prevent misuse. | |

| Protection function | Input/output phase failure protection ,Overcurrent protection ;Over voltage protection; Undervoltage protection; Overheat protection ; Overload protection | |

| Options | Brake assembly, PG card | |

| Environment | ||

| Application environment | In-door, free from direct sunlight, dust , corrosive gas, combustible gas, oil mist , steam , water drop and salt . | |

| Altitude | Lower than 1000m | |

| Vibration | Less than 5.9m/s(0.6g) | |

Technical characteristics

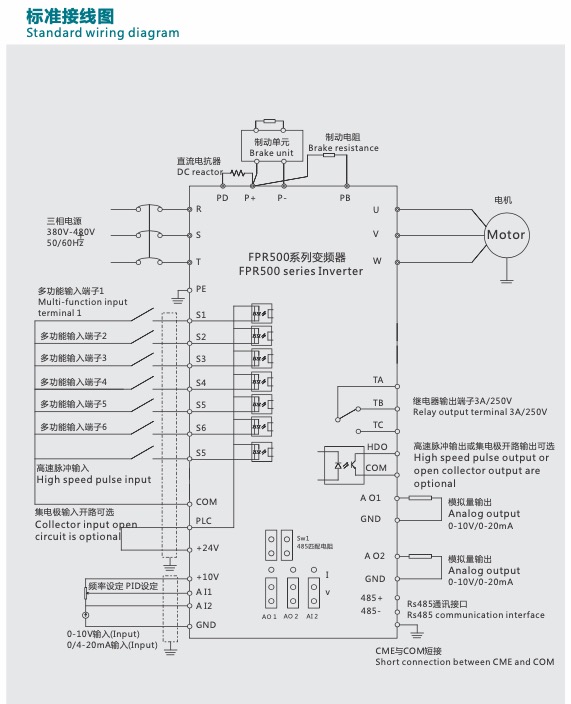

Wiring diagram:

Factory tour: