Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Tech parameters of Automatic hot melt Extruder Machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 0-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 750kg |

Equipment details of Automatic Butyl Extruder Insulating Glass machine

Germany Siemens parts

Butyl extruder machine Adopt German brand Siemens PLC, stable performance.

KINCO Touch Screen

Use toubh screen operation ,simple trial,Clear interface, Simple operation, Smart touch screen,Updated programming.

Germany HAVE Valve

High speed butyl extruder machine Adopt Germany’s Harvey valve, more stable performance.

Alarm system

Adopt Automatically alarm system, reminding adding butyl.

Glue cylinder

The rubber cylinder adopt the pull-up structure, which is convenient for changing butyl.

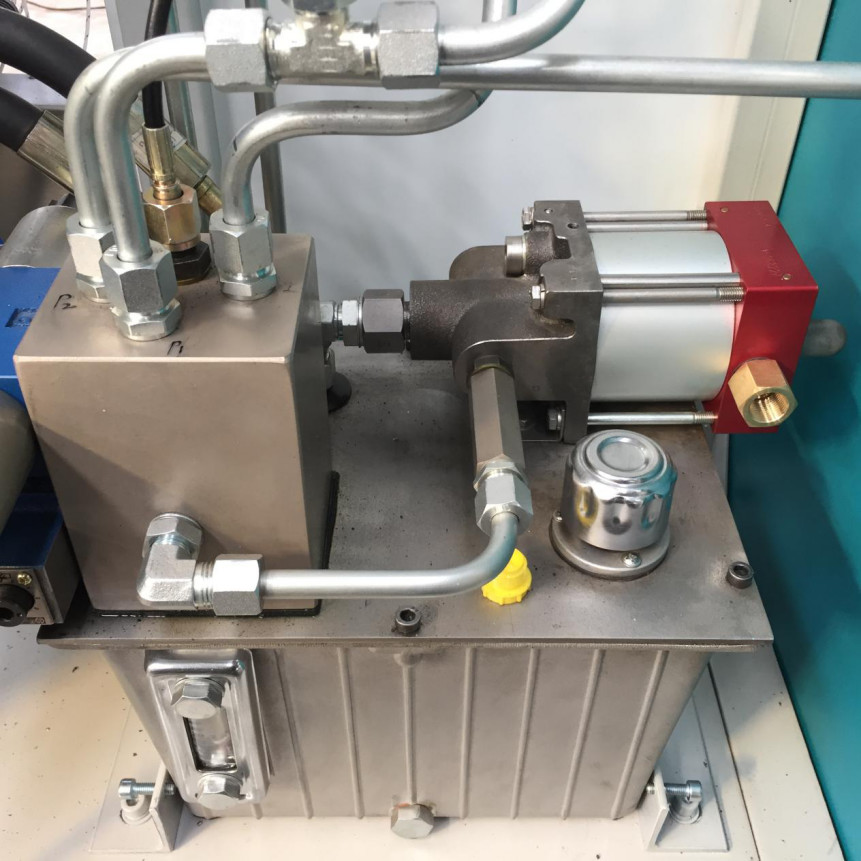

Germany Maximator Cylinder

Super charging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

Adjust the glue putput automatically according to the speed change

The height adjustment of beam is convenient,effective to solve the provlem of white line

Optional functions of Automatic butyl coating machine:

200L glue cylinder is optional

Related Products of LIJIANG GLASS

2.Desiccant Filling Machine LJGZ 2020A

Technical data

| Max frame size | 2000mm*2000nn (2500mm*2500mm) |

| Min frame size | 300mm*250mm |

| Aluminum specifications | 6A - 27A |

| Air source | ≥0.65MPa |

| Power supply and power consumption | AC220V 50Hz 1.5KW |

| Molecular sieve diameter needed | 0.5-0.8mm |

| Dimension | 1650mm*1100mm*3600mm |

3.Automatic Aluminum Spacer Bending Machine LJZW2020