Dongguan YiCun Intelligent Equipment Co.,Ltd |

|

Specification (Customized design is available according to customer

requirements)

1. Total equipment length: 6000mm

2. Working area length: 5000mm

3. Feeding operation area: 450mm Discharging operation area: 450mm

4. Height of entrance and exit: 200mm

5. Conveyor width: 1000mm

6. Conveyor belt from the ground: 750 ± 20mm

7. A total of 80 lamps are installed in the sterilizer, each power

30W

Structure

1. Work area tunnel body: high-quality SUS304 stainless

steel

2. Working area tunnel cavity: mirror stainless steel Model: # 304

3. Body support frame: one set of Square Steel Model: 2 ″

4. Air transport system: a set of forced air transport exhaust fans

(extracting harmful gas) Model: 6 inches

5. Thermal insulation material: Vacuum aluminum silicate + silk

cotton double layer Model: 60K

6. Conveyor belt: Teflon mesh belt 1. Main switch: 20A

7. Transport motor: 800W (inverter speed regulation)

8. Speed governor: 500W (electronic stepless inverter speed

regulation digital display speed operation)

9. Exhaust fan: CY-125

10. Ammeter: 50A set

11.Voltage: 220V

12. Working voltage: 200V--220V (± 5) Three-wire system 50Hz

Usage Instructions

Effective light moment of ultraviolet light source: 150mm

Tube length 460mm

16 UV germicidal lamp tubes * 20W UV lamps are located in the inner

cavity longitudinally,

and there are installed on the top, bottom, left and right

The wavelength is 253.7nm, and the radiation intensity at a

distance of 1 meter is more than 160 microwatts per square

centimeter.

Power supply equipment and precautions

(1) Power supply: AC220V 3Φ 2.35KW 50Hz

※ Allowable fluctuation range of voltage: ± 5% of rated value

※ (but the operating range is ± 10%)

(2) Maximum load capacity: 2.35 KW

(3) Maximum current: 50A

(4) When placing the box, pay attention to the distance from the

wall should be greater than 100 mm.

Maintenance and maintenance of UV sterilizer:

1 Regular inspection to ensure the normal operation of the UV lamp.

2. After continuous use for 8000 hours or one year, the UV lamp

should be replaced. When replacing a new lamp, first unplug the

lamp power socket and take out the ultraviolet lamp. Be careful not

to touch the quartz glass of the new lamp with your fingers, as the

stain will affect the intensity of the light. At the same time,

carefully put the lamp into the interior of the sterilizer.

Safety equipment

Temperature over-rise preventer (to protect the test article and test box)

Fault alarm prompt

Overvoltage and over-current protection

Equipment overload protection

| Item | Index | Test Method | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Total number of colonies, CFU/g ≦ | 1000 | GB 4789.2 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Coliform bacteria, MPN/100g ≦ | 40 | GB 4789.3 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

| Pathogenic bacteria (Salmonella, Shigella, Staphylococcus aureus) | Shall not be detectable | GB 4789.4 GB 4789.5 GB 4789.10 | |||||||||||||||||||||||||||||||||||||||||||||||||||||

Serilizing parameter | |||||||||||||||||||||||||||||||||||||||||||||||||||||||

| |||||||||||||||||||||||||||||||||||||||||||||||||||||||

Advantages of UV disinfection technology

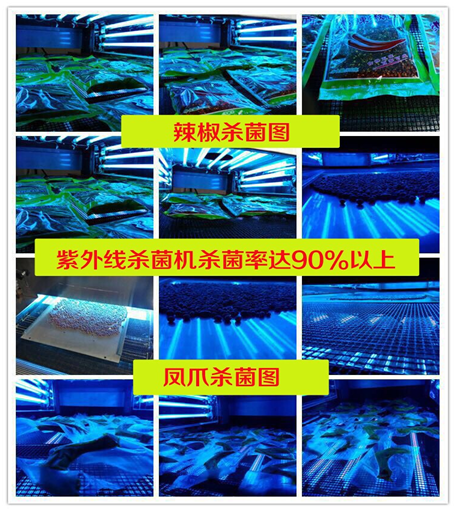

The disinfection effect of ultraviolet C disinfection technology on

bacterial viruses and other pathogens has been recognized

worldwide, and it has unparalleled bactericidal efficiency. The

germicidal effect of ultraviolet rays on bacteria and viruses is

generally within one second. For traditional chlorine and ozone

methods, it takes 20 to 50 minutes to achieve the sterilization

effect of ultraviolet rays. It has a broad spectrum of efficient

sterilization, no secondary pollution, safe and reasonable design,

safe and reliable operation. Simple maintenance and low cost. This

equipment occupies a small area and has no noise. It can

continuously sterilize in large quantities, and has a wide range of

applications.

Application

Ultraviolet disinfection technology is the latest generation of disinfection technology emerging in the late 1990s. It integrates optics, microbiology, electronics, fluid mechanics, and aerodynamics. It has the characteristics of high efficiency, broad spectrum, low cost, long life, large water volume and no secondary pollution. Mainstream consumer technology.

Mainly used to sterilize cooked food and water. Widely used in hospitals, food, Chinese herbal medicine, food and beverage processing and packaging equipment, health care products factory, food factory, dairy factory, brewery, beverage factory, bakery and packaging products factory, etc. The working principle of the equipment is that the ultraviolet sterilization band is mainly between 200-300nm, and the sterilization ability with the wavelength of 253.7nm is the strongest. When various bacterial viruses in water or air pass through the ultraviolet (253.7nm wavelength) irradiation area, ultraviolet rays penetrate the cell membrane and nucleus of microorganisms, destroying molecular bonds of nucleic acid (DNA or RNA), causing them to lose their replication ability or activity and die. To kill all bacterial viruses without using any chemicals. The germicidal lamp does not need to be converted into visible light, and the wavelength of 100-200nm can play a good sterilizing effect. This is because the cell has a regular absorption spectrum of light waves. Ultraviolet rays at 100-200nm have the greatest absorption. The absorbed ultraviolet rays actually act on the cell's genetic material, namely DNA. The energy is absorbed by the base pairs in the DNA, causing genetic material to mutate, causing the bacteria to die immediately or fail to reproduce offspring, thereby achieving the purpose of sterilization.