Henan Yuanda Boiler Co., Ltd. |

|

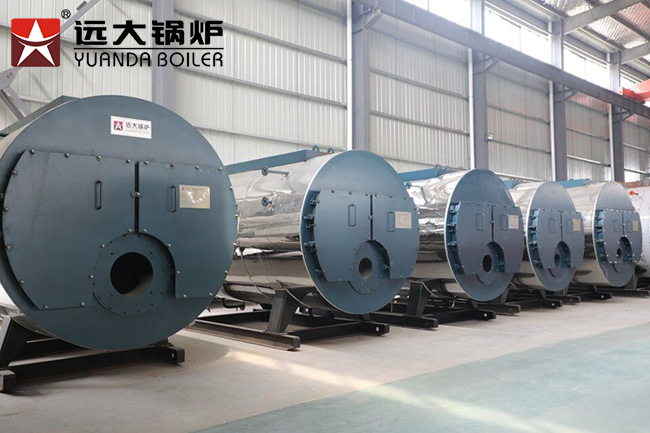

Automatic Water Feeder 2000Kghr Gas Fired Steam Boiler For Soft Drinks Plant

General introduction:

WNS series gas/oil fired industrial steam boiler is horizontal

three pass fire tube wet back full automatic steam boiler. It

normally suitable for 500kg to 20ton/h capacity, use all kinds of

gas and oil fuels,such as natural gas, lpg,lng,cng,city gas,biogas,

diesel oil,heavy oil.

1.Model:WNS

2.Steam Capacity: 500kg/hr-20ton/hr

3.Design pressure:1.0Mpa(10bar), 1.25Mpa(13bar),

1.6Mpa(16bar),2.5Mpa(25bar)

4.Stem temperature: below 224 degree

5.Design fuel:natural gas, lpg, lng, cng, city gas, biogas, diesel

oil, heavy oil

6.Structure: three pass fire tube wet back

7.Application: boiler for textile mill, milk

pasteurization,corrugated machine, sugar factory,pringting dyeing

mill,medicine industry, food & beverage industry, chemical

industry, garment industry, food processing industry, and wood

processing industry, etc.

Core Technology:

1. Independently research and develop PLC control system, intelligent matching, rich functions, safe and convenient;

2. Automatic control of boiler water level, over-high,over-low water level and over-pressure alarm function, adding the fifth water level protection;

3. Flame-out protection, power failure self-locking protection function;

4. Boiler operation data query and automatic fault identification function;

5. Data collection, analysis, storage and remote monitoring of the Internet.

6.Industrial packaging design, beautiful and durable.

Wns diesel oil steam boiler technical parameter

| Boiler model | Capacity | Pressure | Feed temp. | Steam temp. | Fuel consump. | Thermal efficiency | Weight | |

| Light oil | Heavy oil | |||||||

| t/h | Mpa | ℃ | ℃ | kg/h | kg/h | % | ton | |

| WNS1-1.0-Y(Q) | 1 | 1 | 20 | 184 | 65.5 | 67.3 | 91 | 4.3 |

| WNS 2-1.25- Y(Q) | 2 | 1.25 | 20 | 194 | 129.6 | 132.2 | 92 | 7.2 |

| WNS3-1.25-Y(Q) | 3 | 1.25 | 20 | 194 | 192 | 195 | 92.1 | 8 |

| WNS4-1.25- Y(Q) | 4 | 1.25 | 20 | 194 | 256 | 261.9 | 93 | 9.6 |

| WNS5-1.25- Y(Q) | 5 | 1.25 | 20 | 194 | 318 | 322 | 93 | 12.5 |

| WNS6-1.25- Y(Q) | 6 | 1.25 | 20 | 194 | 380 | 390.6 | 93.2 | 16.5 |

| WNS8-1.25- Y(Q) | 8 | 1.25 | 20 | 194 | 503 | 517 | 93.5 | 24.8 |

Notes: The lower heating value of the fuel is calculated by the following values, light oil 10240kcal/kg, heavy oil 10000 kcal/kg, natural gas 8000kcal/Nm3, liquefied gas 24000 kcal/Nm3, and city gas 3800 kcal/Nm3. The parameters are for reference only. If the technology is improved, please refer to delivery technical parameters.

Application fields

1. Food industry: such as juice processing factory, tomato sauce

factory, wine factory, rice mills,etc.

2. Petrochemical industry: steam can be used to heat oil, to

strengthen the liquidity of oil;

3. Foam, furniture production: the steam can be used for producing

foam. When making furniture, wood needs to be dried with steam;

4. Filling block production:steam used for drying the aerated

brick;

5. Washing ironing industry: generally used in laundry, including

dry cleaning machines, dryers, washing machines, dehydration

machines, ironing machines, iron and other equipment supporting the

use;

6. Packaging machinery industry: labeling machines, sets of

standard machine;

7. Bio-chemical industry: fermentation tank, reactor, sandwich pan,

mixer, emulsifier and other equipment;

8. Food machinery industry: tofu machine, steamer, sterilization

tank, packaging machines, paint equipment, sealing machines and

other equipment;

Yuanda Boiler Service:

1. Pre-sale service:

We help customer choose the best boiler model according to different requirements of various industry. Before delivery we will provide foundation drawing, layout drawing, boiler room layout, etc.

2. In-sale service:

We keep 24 hours online and keep close contacts during the production process to ensure on time delivery with perfect finished product.

3. After-sale service: