Anhui Jateke Heavy Bearing Co., Ltd. |

|

Verified Suppliers

|

|

JATEC 6200-2RZ Product introduction

6200-2RZ

Description

Deep groove ball bearings are mainly used to bear pure radial load, but also can bear radial load and axial load. When it is subjected to pure radial load, the contact Angle is zero. When the deep groove ball bearing has large radial clearance, it has the performance of angular contact bearing and can withstand large axial load. The friction coefficient of deep groove ball bearing is very small, the limit speed is very high, especially in the high speed operation condition of great axial load, deep groove ball bearing is more superior than thrust ball bearing.

Structure

Compared with other types of deep groove ball bearings, the structure is simple and the manufacturing precision is high. Therefore, it is easy to mass produce, the manufacturing cost is also low, and the use is extremely common. In addition to the basic type of deep groove ball bearings, there are a variety of structural variations, such as deep groove ball bearings with dust cover, deep groove ball bearings with rubber sealing ring, deep groove ball bearings with stop groove, deep groove ball bearings with ball gap large load capacity, double row deep groove ball bearings.

Raw Material & Capacity

| Part No. | Components | Raw Material | Dimension/mm | Rated Load/KN | Weight | |

| Cor | Cr | |||||

| 6200-2RZ | Outer Ring | Gcr15/G20CrNi2MoA | 10x30x9 | 5.4 | 2.36 | 0.032kg |

| Inner Ring | Gcr15/G20CrNi2MoA | |||||

| Roller | Gcr15/G20CrNi2MoA | |||||

| Cage | Steel/Brass/Polyamide | |||||

| Retainer | Steel/Brass/Polyamide | |||||

| Space Ring | Steel/Brass/Polyamide | |||||

Advantages

1. Deep groove ball bearings are suitable for high speed or even extremely high speed operation, and very durable, without frequent maintenance.

2. Deep groove ball bearing this kind of bearing friction coefficient is small, high limit speed, simple structure, low manufacturing cost, easy to achieve high manufacturing accuracy.

3. The size range and form of deep groove ball bearings are varied. They are used in precision instruments, low noise motors, automobiles, motorcycles and general machinery industries, and are the most widely used bearings in the machinery industry.

4, deep groove ball bearings are mainly used to bear radial load, but when the radial clearance of the bearing is increased, it has a certain performance of angular contact ball bearings, which can bear diameter and axial combined load.

5. After the deep groove ball bearing is installed on the shaft, the axial displacement of the shaft or shell in two directions can be limited within the axial clearance range of the bearing, so the axial positioning can be made in both directions. In addition, this kind of bearing also has a certain aligning ability. When tilted 2 to 4 degrees relative to the shell hole, it can still work normally.

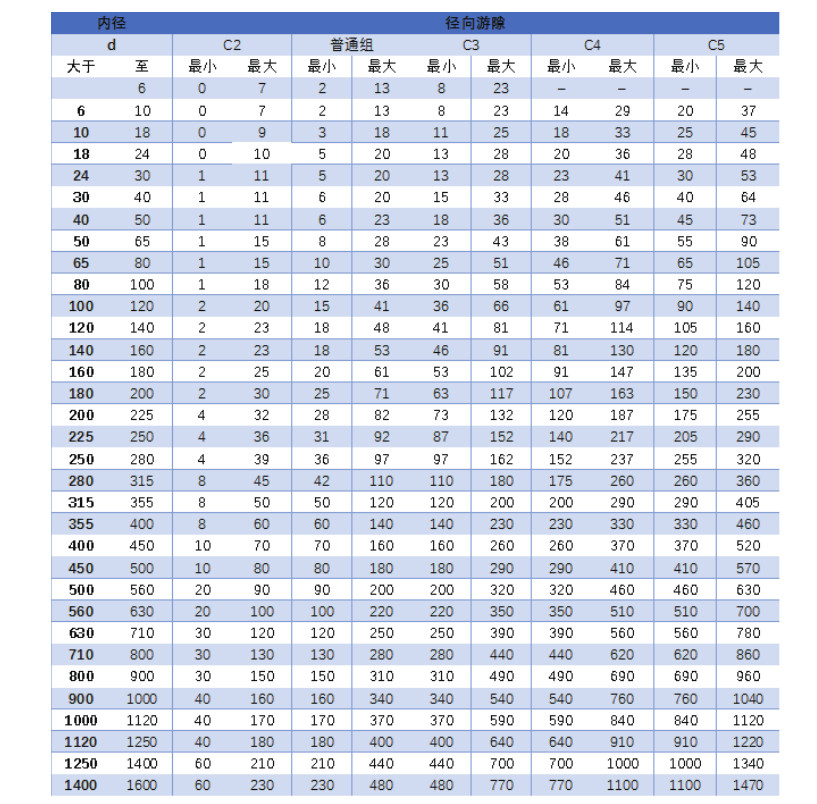

Clearance of Deep Groove Ball Bearing

Universal Failure Modes

1. Fatigue flaking

The inner and outer ring raceways and rolling surfaces of deep groove ball bearings should bear load and relative rolling. Due to the action of alternating load, cracks (maximum shear stress) are formed under a certain depth of the surface, and then extend to the contact surface, so that the surface surface spalling pit, and finally develop into a large area of spalling, this phenomenon is fatigue spalling. According to the test procedures, the area of the fatigue spalling pit on the raceway or roller is 0.5mm2, which is regarded as the end of the bearing life.

2. Wear and tear

Due to the invasion of dust and foreign matter, the relative movement of raceway and roller will cause surface wear, and poor lubrication will aggravate the wear. Wear leads to the increase of bearing clearance and surface roughness, reduces the running accuracy of bearings, thus reduces the motion accuracy of machine tools, and increases vibration and noise.

3. Deformation

When the bearing is subjected to excessive impact load or static load, or the additional load caused by thermal deformation, or very hard foreign body intrusion will form a dent or scratch on the raceway surface. Once the indentation occurs, the impact load generated by the indentation will further lead to the spalling of the nearby surface.

4. Rust

Water or acid or alkaline substances can cause bearing corrosion. When the bearing stops working, the temperature of the bearing drops to the dew point, and the water in the air condenses into water droplets attached to the bearing surface, which will also cause corrosion. In addition, when a current passes through the bearing, the current may pass through the contact point on the raceway and the rolling body, and the extremely thin oil film causes electric spark and electric corrosion, forming a washboard shape with uneven surface.

5. Broken

Overload may cause rupture of bearing components. Improper grinding, heat treatment and assembly will cause residual stress, and excessive thermal stress will also lead to the fracture of bearing parts. In addition, improper assembly method and process may also cause the loss of block at the flange of bearing ring and roller chamfer.

6. Bonding

When bearing parts work under the condition of poor lubrication, high speed and heavy load, they can reach a very high temperature in a very short time due to friction and heating, causing surface burns and bonding. Bonding refers to the phenomenon of metal on the surface of one part sticking to the surface of another part.

7. Cage damage

Improper assembly or use may cause the cage to deform, increase the friction between it and the rolling body, or even make some rolling bodies stuck and unable to roll, which may cause friction between the cage and the inner and outer rings. Such damage will further aggravate vibration, noise and heat, resulting in bearing damage. The bearing should be installed correctly to ensure the normal operation of the bearing

笔记

JATEC Internal control size chart

| Items(Um) | Outer ring | Inner ring | Rollers |

Datum end face flatness Double-ended parallelism | ≤0.003 ≤0.003 | ≤0.002 ≤0.003 | ≤0.001 ≤0.001 |

| Datum end face roughness | ≤0.32 | ≤0.32 | ≤0.32 |

| Outer ovality/roundness | ≤0.003/≤0.003 | ≤0.003/≤0.002 | ≤0.002 |

| Raceway ovality/roundness | ≤0.003/≤0.003 | ≤0.003/≤0.002 | |

| Inner hole ovality/taper | ≤0.003/≤0.003 | ≤0.003/≤0.002 | |

| Raceway milling/ super roughness | ≤0.32/0.08 | ≤0.32/0.032 | ≤0.025 |

| Size scattering | ≤0.01 | ≤0.01 | ≤0.002 |

| Tertiary/quadratic detection | ≤0.0001 | ≤0.0001 | ≤0.0001 |

| Full inspection of surface quality | Eddy current flaw detection | Eddy current flaw detection | Eddy current flaw detection |