Chengdu Yongyi Pump Industry Co., Ltd. |

|

380V Brass Vortex Impeller Peripheral Pump Electric Chemical Pump Self Priming

Product Introduction

XWD series vortex pump has high safety and reliability, strong versatility and wide application range. At the same time, it adopts the current general structure, bracket support, front and rear door opening. It is very safe and convenient to disassemble and maintain with lower cost.

XWD series vortex pump adopts CAD modular structure design, component assembly, more than 20 models, only 5 bearing bodies and bearing body brackets. The parts of the same series have great interchangeability. The inlet and outlet flanges of the pump adopting GB91131-2000PN1.6Mpa (16bar standard flange), it can also use flange of different standards according to user requirements.

XWD series vortex pump is integral casting with semi-open impeller. The pump body adopts wide flow channel, which makes the pump adaptable to working conditions and the medium passed easily. It is especially suitable for medium which is high solid content, high viscosity, easy crystallization. It has high efficiency and excellent anti-cavitation performance. The impeller has back blades, which can reduce the axial thrust, prevent the solid particles from entering the auxiliary impeller, reduce the abrasion of the auxiliary impeller and prolong the impeller’s service life.

XWD series pump shaft seals adopt the vice impeller + packing dynamic seal, single-end mechanical seal, back-to-back double-end mechanical seal, series double-end mechanical seal and the cartridge seal.

Technical Parameter

Model | Clean Water Performance | ||||

Flow (m³/h) | Head (m) | Rotating Speed (r/min) | Efficiency (%) | NPSHr (m) | |

| 40XWD-250 | 8-20 | 15-27 | 1450 | 29 | 2.4 |

| 40XWD-315 | 10-30 | 25-40 | 1450 | 32 | 2.6 |

| 50XWD-250 | 30-50 | 15-28 | 1450 | 35 | 2.5 |

| 50XWD-315 | 30-50 | 25-40 | 1450 | 35 | 2.6 |

| 50XWD-400 | 30-50 | 38-60 | 1450 | 32 | 2.8 |

| 65XWD-250 | 50-80 | 15-25 | 1450 | 38 | 2.2 |

| 65XWD-315 | 50-80 | 25-40 | 1450 | 40 | 2.4 |

| 65XWD-400 | 50-80 | 38-60 | 1450 | 37 | 2.6 |

| 80XWD-250 | 80-120 | 15-25 | 1450 | 45 | 2.6 |

| 80XWD-315 | 80-120 | 22-38 | 1450 | 46 | 2.7 |

| 80XWD-400 | 80-120 | 35-55 | 1450 | 47 | 2.9 |

| 100XWD-250 | 120-180 | 10-20 | 1450 | 51 | 2.7 |

| 100XWD-315 | 120-180 | 18-35 | 1450 | 52 | 2.8 |

| 100XWD-400 | 120-180 | 35-50 | 1450 | 54 | 2.8 |

| 125XWD-250 | 180-250 | 10-20 | 1450 | 55 | 2.9 |

| 125XWD-315 | 180-250 | 18-35 | 1450 | 57 | 3.1 |

| 125XWD-400 | 180-250 | 35-50 | 1450 | 60 | 3.2 |

| 150XWD-315 | 250-350 | 20-35 | 1450 | 62 | 3.2 |

| 150XWD-400 | 250-350 | 32-50 | 1450 | 65 | 3.2 |

| 300XWD-315 | 350-650 | 20-30 | 1450 | 65 | 3.3 |

| 200XWD-400 | 650-650 | 28-45 | 1450 | 67 | 3.3 |

| 250XWD-400 | 450-750 | 28-45 | 1450 | 69 | 3.3 |

Application

♦ central heating system water supply and sewerage |

♦ iron and steel metallurgy enterprises |

♦ paper mills |

♦ petrochemical refineries |

♦ oil fields |

♦ construction of thermal power plants and power stations |

♦ airports, chemical factories |

♦ textile mills, sugar factories |

♦ chemical plants, power stations |

♦ mines |

♦ farmland drainage irrigation and hydraulic engineering. |

Operation Data

| Model | XWD-series vortex pump |

| Pressure | 1.6MPa |

| Capacity | 8~750m³/h |

| Head | 69% |

| Maximal Efficiency | 2.4m~3.3m |

| NPSH | up to 1500kg |

| Pump Weight | 1450r/min |

| RPM | 1450r/min |

| Motor Power | 250KW |

| Temperature | -50℃-130℃ |

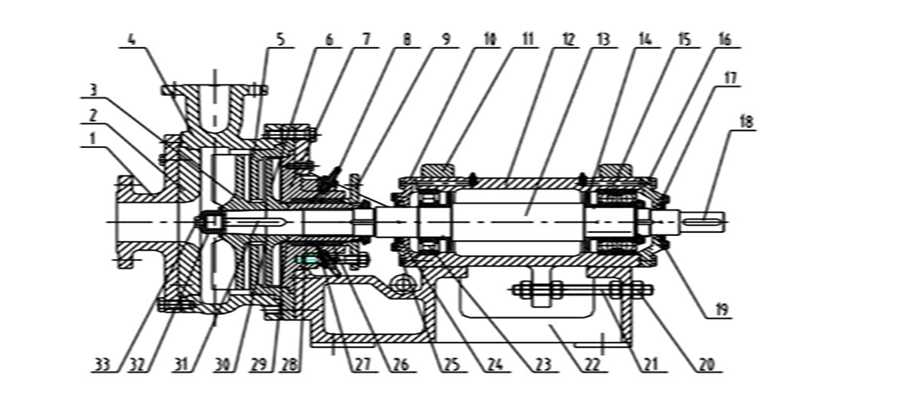

Structure

1 | front cover | 8 | rinsing nozzle | 15 | rear bearing | 22 | bearing body bracket | 29 | O-ring |

2 | wear-resist plate | 9 | packing gland | 16 | rear bearing cover | 23 | front bearing | 30 | O-ring |

3 | impeller | 10 | front bearing cap | 17 | rear oil seal gland | 24 | framework oil seal | 31 | key |

4 | pump body | 11 | bearing body bracket | 18 | key | 25 | front oil seal gland | 32 | impeller nut |

5 | vice impeller chamber | 12 | bearing body | 19 | framework oil seal | 26 | filler | 33 | lock screw |

6 | vice impeller | 13 | bearing | 20 | adjustment nut | 27 | water seal ring |

|

|

7 | packing room | 14 | oil baffle pan | 21 | adjustment screw | 28 | sleeve |

After service

1. Routine tracing will be done timely.

2. Provide Clients one-year warranty to make sure the machine work well.

3. Suggestions and any comments & reflection from customer would be treated in priority.

FAQ

1. Q: Are you a manufacturer or trading company?

A: We are a manufacturer established in 1995, professional

manufacturer of chemical-process pump and energy-saving mixer with

more than 20-year experience.

2. Q: What's your delivery time?

A: The batch order will be shipped within 40 working days after

receiving deposit.

3. Q: What's your warranty service policy?

A: 12 Months for all products, and some products warranty is

24months.

4. Q: What information I need to offer for quotation?

A: Medium: ____________

PH: ________

Specific Gravity: _______

Temperature: _________

Capacity/Flow: ________m3/h Head:

_________m

Voltage: ____________V

Frequency: _________Hz

Power:_____________KW

5. Q: What is your minimum quantity?

A: One set is also welcomed to us.