Chengdu Yongyi Pump Industry Co., Ltd. |

|

Durable Cast Iron Vertical Submersible Pump, Electric Industrial Centrifugal Chemical Pump

Brief Description

Ductile iron casing provides durable, safety and long service life.

The impeller and liner are all made of high chrome alloy(Cr26) material withfeatures of anti-wear, anti-abrasive, high efficiency and long service life.

Cylindrical structure, adjusting the space between impeller and front liner easily. They can be removed completely when being repaired.

Bearing assembly use grease lubrication.

Technical Data

| Model: ZAL-series vertical submerged centrifugal pump |

Discharge Size: 32mm~200mm | |

Inlet Size: 50mm~250mm | |

Capacity: 5~500 m³/h | |

Head: 10 ~ 70 m | |

Maximal Efficiency: 70% | |

NPSH: 1.4m~4.5m | |

Allowable Max Motor Power: 315 kw | |

Impeller | Allowed Max Particle Size: / |

Vanes: 5/6 | Seal Type: packing seal |

Type: closed | Pump Weight:up to 3000kg |

Material:Metal (according to working conditions ) | RPM: 1450 r/min or 2900 r/min |

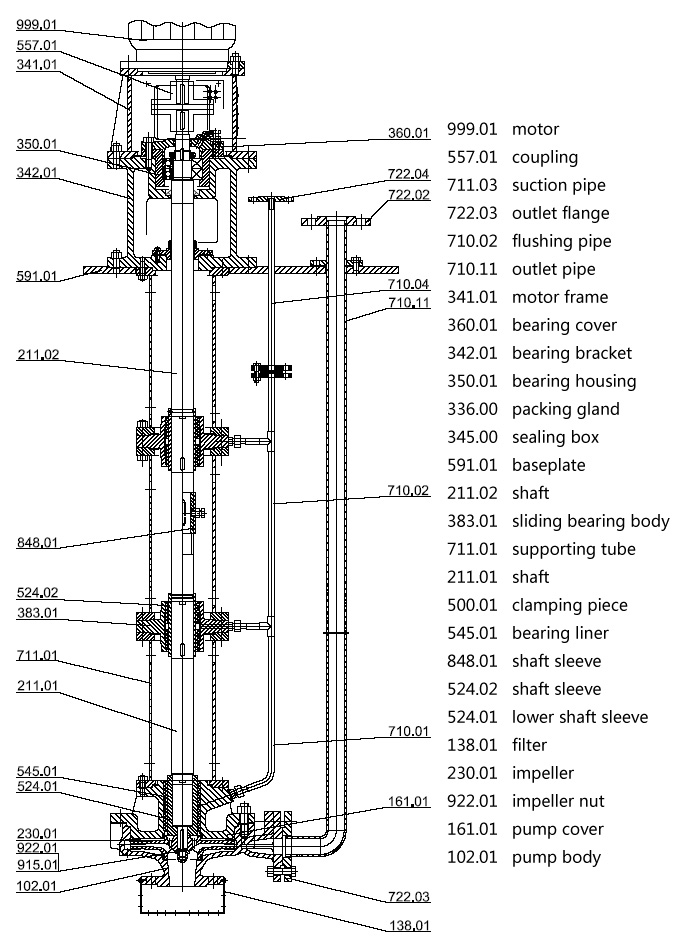

Structure

Technical Parameter

Model | rotate speed n=2950r/min | rotate speed n=1475r/min | ||||||

Flow (m3/h) | Head (m) | ρ=1 | ρ=1.35 | Flow (m3/h) | Head | ρ=1 | ρ=1.35 | |

Motor power | Motor power | |||||||

ZAL25-200 | 7.5-11.5 | 28-49 | 2.2-5.5 | 3-7.5 | 4-5.8 | 6.5-12 | 0.75-1.1 | 0.75-1.1 |

ZAL25-250 | 10.8-12.5 | 46-78 | 5.5-11 | 7.5-15 | 5.4-6.3 | 11.5-19.5 | 1.1-1.5 | 1.5-2.2 |

ZAL25-315 | 15.3-20 | 74-130 | 15-30 | 22-37 | 7.6-10 | 18.5-32 | 2.2-3 | 2.2-4 |

ZAL40-160 | 20-28 | 16-33 | 2.2-5.5 | 3-7.5 | 9.5-14 | 4.5-8 | 0.75-1.1 | 0.75-1.1 |

ZAL40-200 | 18-29 | 20-53 | 4-11 | 5.5-15 | 9.5-14.5 | 7-13 | 1.1-1.5 | 1.1-2.2 |

ZAL40-250 | 21-32 | 47-78 | 7.5-18.5 | 11-22 | 10.5-16 | 11-19.5 | 1.1-3 | 1.5-4 |

ZAL40-315 | 29-42 | 61-115 | 15-37 | 22-45 | 15-21 | 15-29 | 3-5.5 | 4-7.5 |

ZAL50-160 | 31-50 | 17-34 | 3-11 | 4-15 | 16.5-25 | 4-8.4 | 0.75-1.5 | 1.1-2.2 |

ZAL50-200 | 43-62 | 28-82 | 7.5-18.5 | 11-22 | 22-31 | 7-13 | 1.1-3 | 1.5-3 |

ZAL50-250 | 50-70 | 45-82 | 15-30 | 18.5-37 | 26-35 | 11-20 | 2.2-4 | 3-5.5 |

ZAL50-315 | 57-87 | 57-115 | 22-55 | 30-75 | 30-44 | 14-28 | 3-11 | 4-11 |

ZAL50-400 | 60-82 | 102-194 | 45-110 | 75-160 | 30-41 | 25-48 | 7.5-15 | 11-22 |

ZAL80-160 | 66-94 | 17-32 | 5.5-15 | 7.5-18.5 | 34-47 | 4-8 | 1.1-2.2 | 1.1-3 |

ZAL80-200 | 70-103 | 30-54 | 11-30 | 15-37 | 36-51 | 7.5-12.5 | 1.5-4 | 2.2-5.5 |

ZAL80-250 | 87-127 | 45-82 | 22-45 | 30-75 | 46-64 | 11-20 | 3-7.5 | 4-11 |

ZAL40-315 | 90-141 | 74-127 | 37-90 | 45-132 | 45-70 | 18-33 | 5.5-15 | 7.5-18.5 |

ZAL80-400 | 116-171 | 95-187 | 75-160 | 90-220 | 53-85 | 25-46 | 11-22 | 15-30 |

ZAL100-160 | 110-162 | 12-29 | 7.5-22 | 11-30 | 55-81 | 3-7.2 | 1.1-3 | 1.5-4 |

ZAL100-200 | 135-193 | 26-50 | 18.5-45 | 30-55 | 70-95 | 6-12.5 | 3-5.5 | 3-7.5 |

ZAL100-250 | 170-230 | 44-79 | 37-75 | 45-90 | 90-115 | 10-20 | 5.5-11 | 7.5-15 |

ZAL100-315 | 170-250 | 71-126 | 75-132 | 75-200 | 86-125 | 17.5-31 | 11-18.5 | 11-30 |

ZAL100-400 | 224-300 | 105-194 | 110-250 | 160-355 | 115-150 | 26-48 | 15-37 | 22-45 |

ZAL150-250 | 310-190 | 40-74 | 55-110 | 75-160 | 155-195 | 10-18.5 | 11-15 | 11-22 |

ZAL150-315 | 310-442 | 68-125 | 90-250 | 132-355 | 150-220 | 17-32.5 | 15-30 | 18.5-45 |

ZAL150-400 | 400-520 | 113-502 | 200-400 | 280-500 | 200-260 | 28-51 | 30-55 | 37-75 |

ZAL150-500 |

|

|

|

| 208-300 | 45-77 | 45-110 | 75-132 |

ZAL150-630 |

|

|

|

| 220-360 | 60-115 | 75-200 | 110-250 |

ZAL200-250 | 470-610 | 32-72 | 75-160 | 90-220 | 240-305 | 8-17.5 | 11-22 | 15-30 |

ZAL200-315 | 480-710 | 65-122 | 132-355 | 185-450 | 350-350 | 15-30 | 18.5-45 | 22-55 |

ZAL200-500 |

|

|

|

| 330-495 | 48-84 | 75-185 | 90-220 |

ZAL200-560 |

|

|

|

| 350-540 | 62-105 | 110-250 | 132-355 |

ZAL200-630 |

|

|

|

| 372-580 | 75-132 | 132-315 | 185-450 |

ZAL250-315 |

|

|

|

| 424-545 | 13-27 | 30-55 | 37-75 |

ZAL250-400 |

|

|

|

| 500-660 | 24-49 | 53-132 | 75-160 |

ZAL250-500 |

|

|

|

| 630-800 | 42-82 | 110-280 | 160-400 |

ZAL250-560 |

|

|

|

| 665-860 | 57-106 | 160-400 | 250-560 |

ZAL300-400 |

|

|

|

| 780-1050 | 26-48 | 90-200 | 132-280 |

ZAL300-500 |

|

|

|

| 870-1240 | 42-78 | 160-450 | 250-560 |

ZAL300-560 |

|

|

|

| 950-1340 | 56-104 | 280-560 | 400-800 |

ZAL300-630 |

|

|

|

| 950-1450 | 75-132 | 355-1000 | 500-1400 |

ZAL300-500 |

|

|

|

| 1300-1870 | 38-74 | 220-630 | 315-1000 |

ZAL300-560 |

|

|

|

| 1500-2040 | 54-98 | 355-900 | 500-1250 |

Flow Part Material

We offer different kinds of anti-abrasive and anti-corrosive high-grade alloy materials to customers, like 304, 316, 316L, 904L, FCr30, CD4MCu, DTCr30, F33, 2507, A33, hastelloy, K alloy, 20# alloy and Lewmet85# alloy

Detail Image

Application

1, Chemical Industry System

2, Sewage System

3, Civil Engineering, Construction System

4, Power Station System

5, Petroleum Industry System

6, Mine Metallurgy System

7, Light Industry System