HENAN DIANYAN NEW ENERGY TECHNOLOGY CO., LTD. |

|

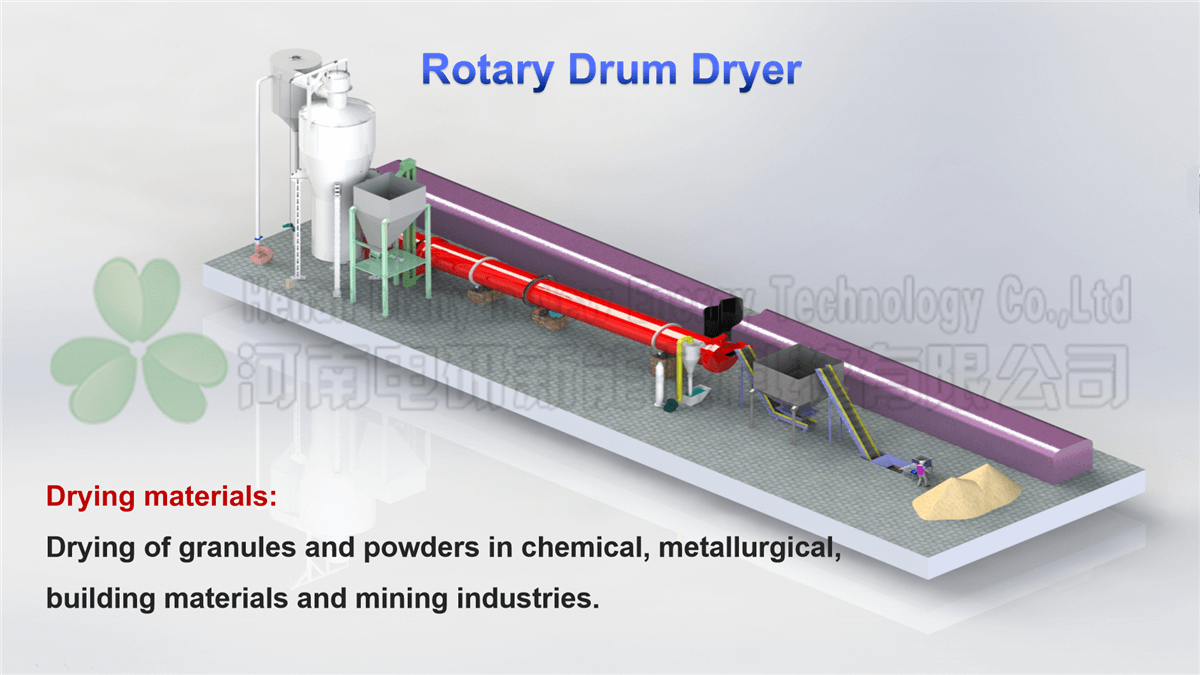

Waste Pretreatment Equipment Rotary Drum Dryer Industrial Dryer Machine

Product Introduction:

Single drum dryer is widely used in building materials, metallurgy, chemical industry, cement, slag, limestone, coal powder, slag, clay and other materials. In addition to producing dryers, our company also produces garbage pretreatment equipment such as shredders, burners, dust collectors and so on. As a garbage pretreatment equipment, the rotary dryer can reduce the moisture content of wet materials to 1% - 0.5%.

Applications

1. Chemical, mining, metallurgical and other industries, such as ore, slag, coal, metal powder, clay, diatomite, kaolin.

2. Agriculture, feed and fertilizer industries, such as straw, pasture, leaves, fish meal, corn paste, starch residue, distiller's grains, medicinal residue, fruit residue, soy sauce residue, bagasse, peat, organic compound fertilizer, sludge, aquatic product waste, food factory waste, slaughterhouse waste, organic fertilizer, inorganic fertilizer, ammonium sulfate phosphate fertilizer.

3. Drying of powdery and granular materials with special requirements. Such as crystals, light calcium carbonate, activated clay, magnetic powder, graphite, inorganic mud, clay, lime slurry, ore slurry, phosphorus slag, red mud of aluminium plant.

4. Require low-temperature drying, and need a large number of continuous drying materials.

Rotary Dryer Structures

Parameters

| Model | Shell diameter (mm) | Shell length (mm) | Shell volume (m3) | Rotary speed (r/min) | Power(kW) | Weight(t) |

HG1.5×15 | 1500 | 15000 | 26.5 | 1--5 | 15 | 19.2 |

FAQ

1) How about the quality of machines?

Our machines adopt advanced technology. Moreover, we carry out

strict supervision during productionand make sure every finished

product with high quality.

2) How about the delivery time?

Generally, it will be about 20-25 days days after your deposit,

which also will be on basis of your order.

3) As for the warranty?

We provide 12 months for warranty.

4) Which kind of payment is available for us?

T/T, L/C and Western Union are common for us.

5) How about the service?

Provide overseas installation, debugging and training the relating

work.

Packaging & Shipping

All the goods exported are packed in wooden case or carton with export standard except naked package when necessary.

We have our own professional shipping company which could deliver the goods to every corners in the world with safety and speed, and aslo can supply the services of solving the problems occured during the transaction, such as customs cleaning.

Water-proof plastic film package with foam protection in each corner

Solid Seaworthy Wood Box Package with Steel Belt

Save space as much as possible for container loading .

Our Service

a. Pre-sale services: enthusiasm, patient

Provide you the proper plan, process flow design and manufacturer

equipment

according to your special demand.

b. Sale services: servant

Send technicians to the job site for guiding the installation and

adjustment, training operators and finishing the check and accept

together with you.

c. After-sale services: faithfulness

To establish long term relationship with you, we will regularly pay

return visit to customers.