oepoch industrial technology |

|

Eccentric rotary valve

General

The eccentric rotary control valve is an eccentric angular stroke regulating valve. The valve body part is composed of a small flow resistance straight-through valve body, a guided eccentric valve shaft and a partial spherical valve plate, and the like. It has the characteristics of small size, light weight, large circulation capacity and high adjustable ratio. This construction is particularly useful in applications containing heavily contaminated media such as pulp, limestone, solid particulate media, viscous media, and cavitation and erosion.

Feature

1. The integral valve body structure (the valve body and the bonnet are integrally molded).Except for the shaft seal, there is no static seal and dynamic seal.

2. The single valve seat design eliminates the problem that the medium in the valve cavity is affected by the abnormal increase of pressure and affects the safety of use.

3. Low torque design. Open and close without friction, when the spool shaft is unscrewed from the closed position, the eccentric design allows the valve plug sealing surface to quickly and smoothly disengage from the valve seat without the need for minimum starting torque. The control valve opens smoothly and has a stable and good control response even at small opening degrees.

5. The sealed seat cover connection between the valve seat and the valve body can make the valve maintenance more convenient.

6. Special design: with thermal insulation jacket, erosion resistant design, suitable for easy crystallization medium.

Technical Parameters

1. Nominal diameter: DN25mm~ 300mm

2. Nominal pressure: PN10,PN16,PN25,Class150,PN40,class150,class300

3. Connection form: flange type.

4. Structural Length: ASME ISA S75.04

5. Seal grade:

Standard Class IV According to ANSI/FCI70-2-2006 standard Metal seat

Bubble Class VI According to ANSI/FCI70-2-2006 standard Soft sealing seat

6. Temperature range: -40 ~400℃

7. Flow characteristics: Approximate linear

8. Adjustable ratio: 100:1

9. The flow direction:

The flow direction of the medium (flow open) is through the seat ring to the spool. This is the standard flow direction.

The flow direction of the medium (flow off).the fluid flows through the spool to the seat ring. (Recommended for fluids with erosion and flashing)

10. Spool rotation: clockwise is closed.

11. Filler application: PTFE(temperature:-40~+200℃), flexible graphite(temperature:-40 ~ +400℃)

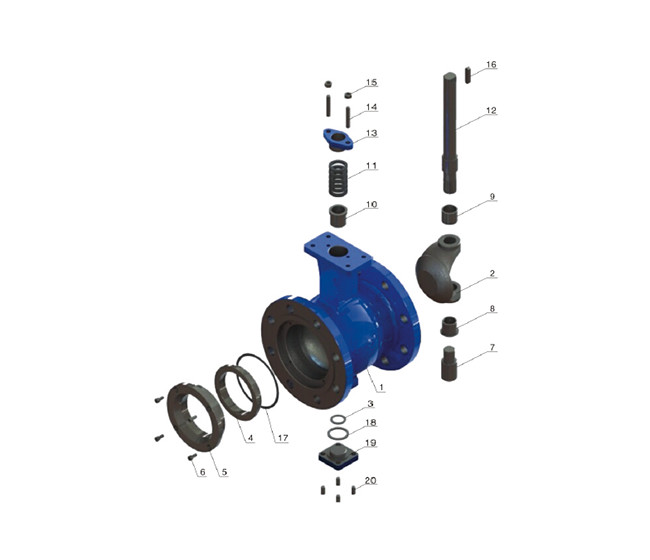

Assembly schedule

| No. | Item | No. | Item |

| 1 | Valve body | 11 | Packing |

| 2 | Spool | 12 | Upper valve stem |

| 3 | Graphite Composite Pad | 13 | Packing gland |

| 4 | Valve seat | 14 | Stud |

| 5 | Pressure ring | 15 | Nut |

| 6 | Socket head cap screws | 16 | Flat key |

| 7 | Lower valve stem | 17 | Adjusting washer |

| 8 | Lower axle sleeve | 18 | Spiral gasket |

| 9 | Middle axle sleeve | 19 | Bottom cover |

| 20 | Upper axle sleeve | 20 | Hex Bolts |

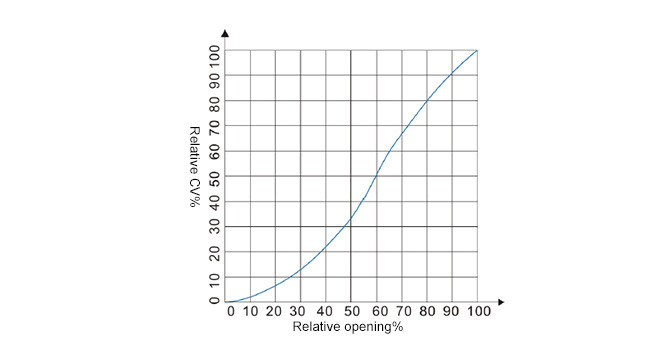

Intrinsic flow characteristics

Intrinsic flow characteristics: Approximate linear

Intrinsic adjustable ratio: 100:1

Flow characteristic curve

Rated flow coefficient CV

| Nominal diameter | Nominal diameter | Rated CV | Rated CV |

| DN | Inch | Hard seal | Soft seal |

| 50 | 2 | 50 | 50 |

| 65 | 2 1/2 | 100 | 85 |

| 80 | 3 | 150 | 120 |

| 100 | 4 | 240 | 195 |

| 125 | 5 | 320 | 290 |

| 150 | 6 | 500 | 480 |

| 200 | 8 | 800 | 800 |

| 250 | 10 | 1250 | 1150 |

| 300 | 12 | 1800 | 1550 |

Packing working temperature, pressure range icon

Standard material combination

| Body material | WCB | CF8 | CF8M | |

| Spool material and treatment | CF8,CF8/HCr,CF8/STL,CF8M/HCr,CF8M/STL | CF8,CF8/HCr,CF8/STL | ||

| Pressure ring material | SS304,SS316 | SS316 | ||

| Seat material and treatment | Hard seal | SS304/ STL, SS316/ STL | SS316/ STL | |

| Soft seal | SS304/ PTFE, SS316/ PTFE | SS316/ PTFE | ||

| Filler material | PTFE, Graphite | PTFE, Graphite | ||

| Stem material and treatment | SS304,SS316,17-4PH | SS316 | ||

| Bushing material and treatment | SS316 nitride | |||

Note: The material grades in the above table are ASTM standards, which are equivalent to or equivalent to other standard materials;

The temperature and pressure of the various materials are not allowed to exceed the temperature and pressure ratings specified in ASTM B16,34;

If you need materials that are not in the table, please contact us.