Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

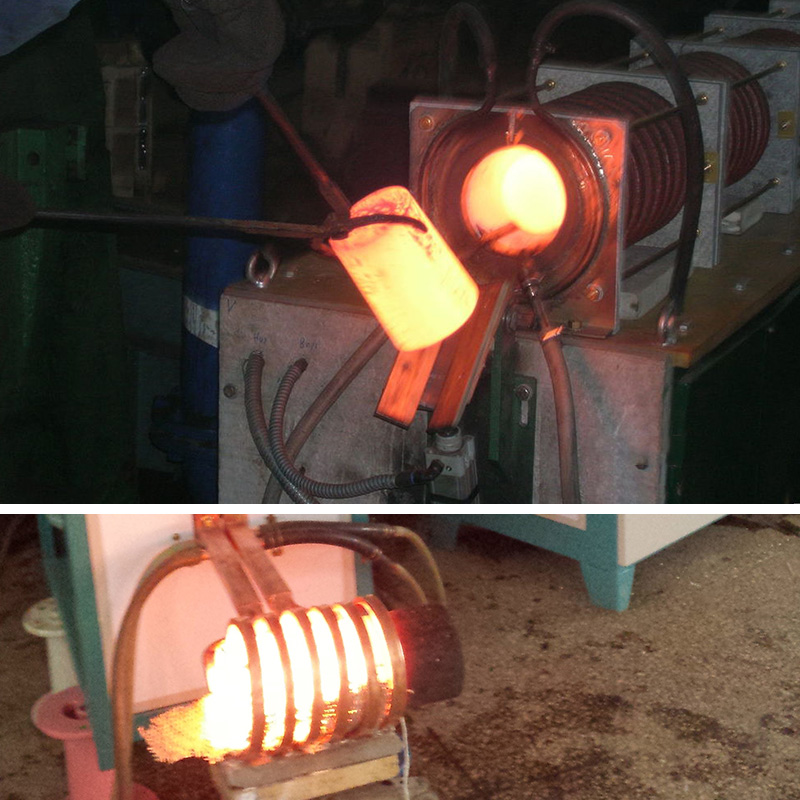

1. Application range(forging furnace induction heating machine):

Medium frequency heating furnace can according to different material heating workpiece geometry and process requirement, Mainly used for gear, axle shaft connecting rod, bearings and other precision forging heating;Also used in bar, long bar temperature, blanking, on-line heating, etc.

Metal materials in the forging. extrusion, hot rolling, shear heating and the modulation of metallic materials as a whole, annealing, tempering heat treatment can be done by the medium frequency heating

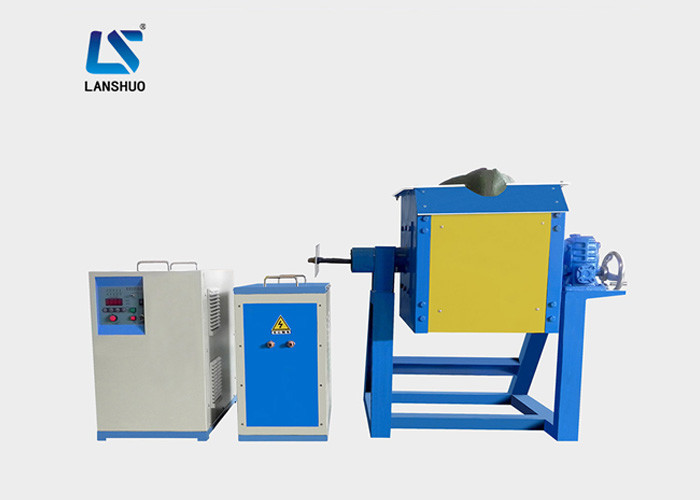

2. Technical Parameters of LSW-200 IGBT induction heating machine:

| Model | LSW-200 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 200kw |

| Oscillation frequency | 10-20KHZ |

| Duty cycle | 100% |

| Cooling water flow | 50L/Min,0.2MPa |

| Weight | 380kg |

| Dimension (L*W*H ) | 1070*640*1870mm / 870*530*600mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating,quenching etc |

3. Features of IGBT induction heating equipment: suitable for heating steel bars, pipes, plates and angle steels.

1. Using high-power MOSFET

2. Using dual-loop PI regulator of voltage and current, the power

range is adjusted from 0-100% .

3. Using pulse width modulation or voltage regulation circuit

microcomputer control based, adjustment stable with high precision,

small harmonic interference.

4. It has fault protection system with over-voltage, over-current,

lack phase and less water-pressure etc.

5.No high voltage operation,maintenance safety,saving electricity

about 30%,water-saving about 50%.

6.Control circuit has a soft start and soft stop function,it will

not has the impact to the electric network.

4. Our Service:

Pre-sale service:

1) Recommend the most suitable machine for customers, according to

their requirements.

2) Inquiry and consulting support.

3) Sample testing support.

4) Visit our factory.

In-sale service:

1) Update the production process timely for you.

2) Carry out test according to relevant equipment test run

regulations.

3) Strictly check up the machine before delivery.

4) Deliver on time.

After-sale service:

1) one year warranty period.

2) At warranty period,the replacement of quality-problem parts is

realized.

3) If any big quality problems occur out of the guarantee period,

we will send maintenance.

4) We will provide a lifetime favorable price to the buyer with the

materials and spare parts used in system operation, equipment

maintenance.

5. Related Products:

| KGPS Melting Furnace | LSZ Melting Furnace | Cooling Tower |

|  |  |