GuangDong Heng AnShun Electrical Power Equipment Service Co., Ltd. |

|

Verified Suppliers

|

|

Porcelain Made High Voltage Electrical Isolator For Outdoor Distribution System Single Phase Vertical Break Switch

Product Description:

High voltage electrical isolators are typically used in high voltage transmission and distribution systems to isolate sections of the network for maintenance or repair work. They are also used as a safety device to protect workers from electrical hazards, such as accidental contact with live parts of the system.

They are designed to handle high voltages and currents, and they are often installed in outdoor locations, where they are exposed to harsh environmental conditions, such as extreme temperatures, wind, rain, and dust. Therefore, they are built to withstand these conditions and are often made of durable materials such as steel or aluminum.

High voltage electrical isolators come in different types and configurations, depending on the specific application and requirements. For example, some electrical isolators are designed for indoor use, while others are suitable for outdoor use. Some are designed to operate manually, while others are automated and can be operated remotely.

In addition to their primary function of isolating circuits, electrical isolators also have other important features, such as providing a visual indication of their status (open or closed), and ensuring that the circuit is not energized when the isolator is open.

Feature:

1.High Voltage Rating: High voltage isolator switches are designed to withstand high levels of voltage, typically ranging from several thousand volts to several hundred thousand volts.

2.Robust Construction: High voltage isolator switches are typically made of materials that are highly resistant to electrical arcing, corrosion, and other forms of damage, such as porcelain or polymer.

3.Arc Chutes: Many high voltage isolator switches are designed with arc chutes, which help to dissipate the heat generated by electrical arcing and prevent damage to the switch.

4.Earth Switch: Some high voltage isolator switches are equipped with an earth switch, which provides an additional level of safety by grounding the isolated section of the circuit.

5.Interlocking Mechanism: To prevent accidental closure of the switch while maintenance work is being carried out, many high voltage isolator switches are equipped with an interlocking mechanism that prevents the switch from being closed until all safety procedures have been followed.

6. Visual Indicators: High voltage isolator switches may also include visual indicators, such as lights or flags, that provide a clear indication of whether the switch is in the open or closed position.

Operation:

1.Closing the Switch: When the switch is closed, the two conductive parts of the circuit are brought into contact with each other, allowing electrical current to flow through the circuit.

2.Opening the Switch: When the switch is opened, an air gap is created between the two conductive parts of the circuit, effectively isolating the section from the rest of the system. This is typically done to allow maintenance, repair, or testing work to be carried out safely.

3.Grounding the Circuit: Before any work can be carried out on the isolated section of the circuit, it is important to ground the circuit to prevent any residual electrical charge from building up. This is typically done using an earth switch or grounding electrode.

Safety Tips:

1.Always wear appropriate personal protective equipment (PPE) such as gloves, safety glasses, and flame-resistant clothing.

Before working on the switch, ensure that the power supply is turned off, and the switch is properly grounded.

2.Follow the manufacturer's instructions for operating the switch, and do not attempt to bypass safety features or use the switch for purposes other than its intended use.

3.When working on the switch, use insulated tools and equipment to prevent electric shock.

4.Avoid touching any conductive parts of the switch and keep a safe distance from the switch when it is in operation.

5.Never attempt to repair or modify the switch yourself unless you are a qualified and trained professional.

6.Keep the area around the switch clean and free of debris that may interfere with its operation.

7.Regularly inspect the switch for signs of wear or damage, and replace any damaged or worn parts as soon as possible.

8.Only authorized personnel should be allowed to operate or perform maintenance on the switch.

9.In case of an emergency, follow established emergency procedures and shut off power to the switch immediately.

Condition:

1.The maximum altitude for installation should not exceed 1000m.

2.The ambient air temperature should not exceed +40'C, and in general areas, it should not fall below -30'C. In Paramos areas, it should not fall below -40'C.

3.The wind pressure should not exceed 700Pa, corresponding to a wind speed of 34m/s.

4.The isolator should be able to withstand earthquakes of up to 8 degrees in intensity.

5.The isolator should be installed in a location where there is no frequent violent vibration.

6.For ordinary type isolators, they should be kept away from gas, smoke, chemical deposition, salt-spray fog, dust, and other explosive and corrosive materials that can seriously affect the isolator's insulation and conduction capability.

7.Pollution-proof type isolators are suitable for use in severely filthy conduction areas, but they should not be installed in areas with any explosive or fire-causing materials.

Technical Parameters:

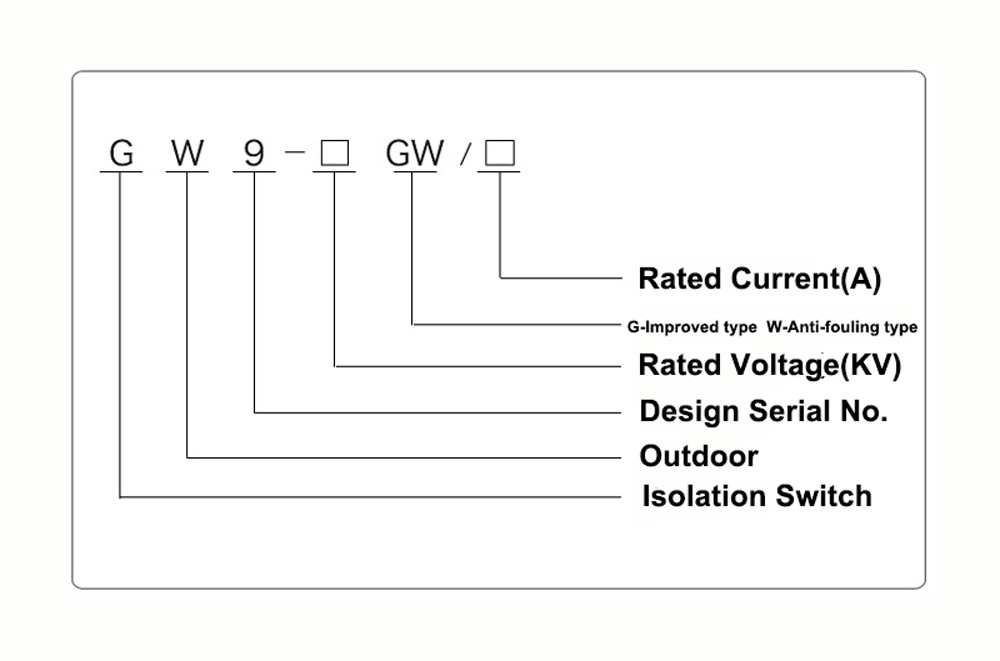

| Serial No. | Parameter | Unit | Data | |||||||||

| 1 | Rated Voltage | kV | 12 | |||||||||

| 2 | Rated Current | Model No. | (H)GW9-12(W)/630-20 | A | 630 | |||||||

| (H)GW9-12(W)/1000-20 | 1000 | |||||||||||

| (H)GW9-12(W)/1250-31.5 | 1250 | |||||||||||

| 3 | 4s Short-time withstanding current | Model No. | (H)GW9-12(W)/630-20 | kA | 50 | |||||||

| (H)GW9-12(W)/1000-20 | 50 | |||||||||||

| (H)GW9-12(W)/1250-31.5 | 80 | |||||||||||

| 4 | Rated Insulation Level | Lightning surge withstand voltage(peak) | Polar-to-Earth (Positive & Negative) | kV | 75 | |||||||

| Interfracture (Positive & Negative) | 85 | |||||||||||

| Industrial frequency withstand voltage (1 min) (Effective value) | Dry Test/Wet Test | Polar-to-Earth | 42(Dry) 34(Wet) | |||||||||

| Interfracture | 48(Dry) | |||||||||||

| 48(Dry) | ||||||||||||

| 48(Dry) 40(Wet) | ||||||||||||

| 5 | Main Circuit Resistance | μ Ω | 630 | |||||||||

| 1000 | ||||||||||||

| 1250 | ||||||||||||

| 6 | Mechanical Life Time | times | 50 | |||||||||

| 50 | ||||||||||||

| 80 | ||||||||||||