Jiangsu Huada Centrifuge Co., Ltd. |

|

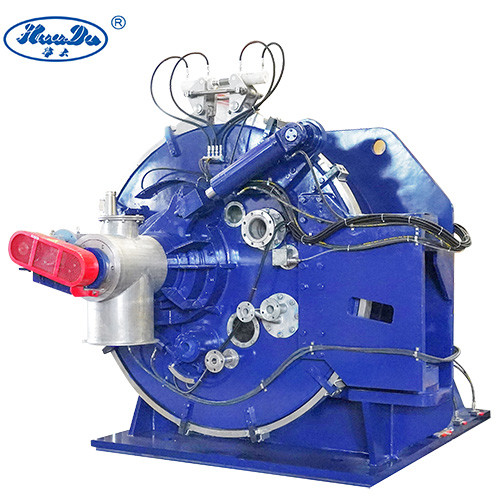

GKH Siphon Tapioca Starch Processing Peeler Centrifuge With Screw Discharge For Food Industrial

Technical Parameters

| Items | Models | |||||

| GKH800 | GKH1000 | GKH1250 | GKH1600 | GKH1800 | ||

| Basket Diameter (mm) | 800 | 1000 | 1250 | 1600 | 1800 | |

| Basket Length (mm) | 450 | 500 | 600 | 1000 | 1250 | |

| Filtering Area | 1.13 | 1.57 | 2.36 | 5 | 7 | |

| Basket Volume (L) | 100 | 165 | 355 | 830 | 1325 | |

| Max. Loading Weight (kg) | 135 | 225 | 450 | 1000 | 1780 | |

| Basket Speed (r/min) | 1550 | 1400 | 1200 | 950 | 800 | |

| Separation Factor | 1078 | 1098 | 1008 | 808 | 645 | |

| Power of Driving Motor (kW) | 45 | 55 | 90 | 132 | 200 | |

| Weight (kg) | Chute | 4500 | 6500 | 10000 | ||

| Chute+Steel Platform | 7000 | 11000 | 20000 | |||

| Floating Platform | 5000 | 6500 | 9000 | 21000 | 33000 | |

| Spiral discharge | 6800 | 10500 | 16000 | 25000 | ||

| Spiral discharge+Steel Platform | 11300 | 22000 | 33000 | |||

Operation process

Feeding

The material enters the rotating basket through the feeding pipe,

and the cake layer controller controls n times of pulse feeding to

fill the basket in limited manner. Usually, the material cake can

reach 75-80% of the basket lip. Feeding is completed once the solid

cake reaches the pre-set thickness.

Filtration Skimming-Filtration

The mother liquid penetrates through the filtration medium across

the inner wall of the basket to complete the primary filtration,

which begins as the material enters and ends as the liquid just

immerses the inner surface of the solid cake. For the mother liquid

containing colloid protein, the mother liquid containing the

colloid protein will be removed by means of the skimming device in

the course of filtration.

Washing

The solid cake is usually washed after the primary filtration. Add

the washing liquid through the feeding pipe or washing pipe, and

level of the washing liquid is monitored in the material level

detector. Washing is completed once the pre-set washing load is

achieved and the solid cake is immersed into the liquid.

Dry spinning

The basket accelerates to the high speed for drying the solid cake,

and filtration is completed after the moisture content of the solid

cake reaches the required value or the solid cake takes the pre-set

drying duration.

Discharging

The solid cake is removed by the scraping device at high speed or

that is decelerating, and the removed cake is discharged through

the discharge mechanism. The solid phase can be discharged in two

modes: discharging chute and scroll conveyor.

Regeneration of filter cloth

Residual solid cake can be found on the inner wall of the basket

after the scraper discharges the material, the filtration basket

can loosen the solid cake through the high-pressure gas on the back

of the basket, and then remove the solid cake by means of the

scraper device. In the siphon basket, the back washing liquid can

be added into the basket from the high-level-mounted back washing

tank through the suction chamber, and then reversely penetrates the

residual solid cake so as to make the solid cake suspended and

restore its permeability.

The siphon-type peeler centrifuge is applicable to the occasions

involving large-scale production and requiring low cake moisture

and sufficient washing, and therefore is commonly used for the

separation of starch, sodium bicarbonate, potassium chloride,

calcium phosphate and other materials. Currently, it has been

widely applied in such industries as pharmaceutical production,

food production, bioengineering and chemical engineering.

Advantages of peeler centrifuge

Feeding phase

As it can freely regulate the filtration rate, the filtration rate

is reduced during feeding phase to prevent uniform distribution of

the cake.

Filtration phase

Siphon pipe is lower level. With the column height Hu of additional

liquid, the filtration rate is increased, and thus the processing

capacity is increased by 50% within the same time.

Washing phase

Inlet of the siphon pipe is in higher level with less filtration

pushing force being generated. The washing liquid flows slowly to

extend the time of the washing liquid staying in the filter cake,

thus reducing loss of the washing liquid and bringing about better

effects of washing.

Dry spinning phase

The inlet of the siphon pipe is at the bottom with the maximum

filtration pushing force, therefore moisture contained in the

filter cake can be removed easily, and the moisture of the filter

cake is reduced.

Back-washing function

After the scraper discharges the material, the siphon can inject

washing liquid into the suction chamber from the outside, and then

reversely force the liquid to flow into the basket for washing.

Achieve good performance of washing the filter cloth with strong

ability to regenerate.