Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Sintering Refractory Silica Checker Brick with Special Shapes High Density

Sintering Refractory Silica Checker Brick with Special Shapes High Density

Sintering Refractory Silica Checker Brick with Special Shapes High Density are produced with silica through adding inflammable substances such as coke, anthracite coal, sawdust, and carbonized rice husk, or foaming agents to form porous structure. Generally add 35-45% anthracite coal or 30% coke as inflammable substances. Since there are Fe2O3 and Al2O3 in the ash of coke and anthracite coal, there is no need to add iron scales. Sintering Refractory Silica Checker Brick with Special Shapes High Density's main mineral composition includes 78%~86% tridymite, 13%~15% cristobalite and 4%~7% quartz. Sintering Refractory Silica Checker Brick with Special Shapes High Density cold crushing strength is 2.0-5.9MPa, thermal conductivity is 0.35-0.42W/(m•K) and density is 0.6-1.2g/cm3.

Sintering Refractory Silica Checker Brick with Special Shapes High Density Properties:

1.Good thermal conductivity

2.Strong high temperature mechanical strength

3.High temperature stable volume change

4.Small residual swell

5.Strong acid-resistant slag erosion

6.Light weight and Eco friendly

7.Good thermal shock resistance

Sintering Refractory Silica Checker Brick with Special Shapes High Density Specifications:

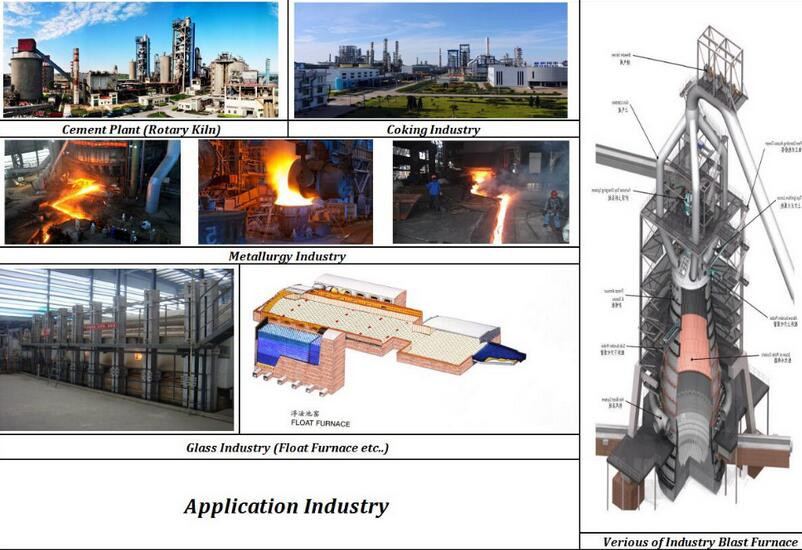

Sintering Refractory Silica Checker Brick with Special Shapes High Density are mainly used in acid furnaces such as glass industry furnaces and coke ovens.

Sintering Refractory Silica Checker Brick with Special Shapes High Density

Packaging detailes of silica brick:

1.International standard seaworthy exportable packing.

2.Wooden pallet.

3.Wooden / bamboo case (box)..

4.Further packing information will be based on customer's

requirements.

Shipping detailes of silica brick:

1.The sample willl be send by International expresses

FEDEX/DHL/UPS/TNT.

2.The goods are transport by shipping.

Payment Item :

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance

before delivery or negotiations to solve.

2. MOQ: Usually 1Tons

3. Quality Warranty: 1 years

Delivery time :

1.Stocks:Within 5-7 days after receive the deposit.

2.Customization:Within 15-30 days after receive the deposite.

1.Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000

tons.

3.Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

Korea, Vietnam, Pakistan, Bulgaria, French, India,

Egypt,Congo, Angola, South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

1. How you can control your quality?

For each production processing, we have complete QC system for the chemical composition and Physical properties. After production, all the goods will be tested, and the quality certificate will be shipped along with goods.

2. What's your delivery time?

It usually needs about 15days- 30 days after receiving the deposit.

3.Do you have any experiences of export?

Yes,and Now we have gained a global sales network reaching Taiwan, Russia, Korea, Vietnam, Pakistan, Bulgaria, French, India, Congo, Angola, South Africa, and so on.

4. Do you provide free samples?

Yes, we can provide a free sample for testing, If we have sample in stock, The quantity based on the material type, The buyer should bear all the shipping costs.

5. Can we visit your Company?

Yes, certainly. You are very welcome to China and we will be honored to have a customer and friend.

Marina Ma

Mobile:+86 18838001797

Email:marina(at)firebricks-supplies.com