Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

high quality silica insulating brick for coke ovens, hot blast

furnaces, glass melting furnaces and carbon calciners

silica insulating brick for coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners

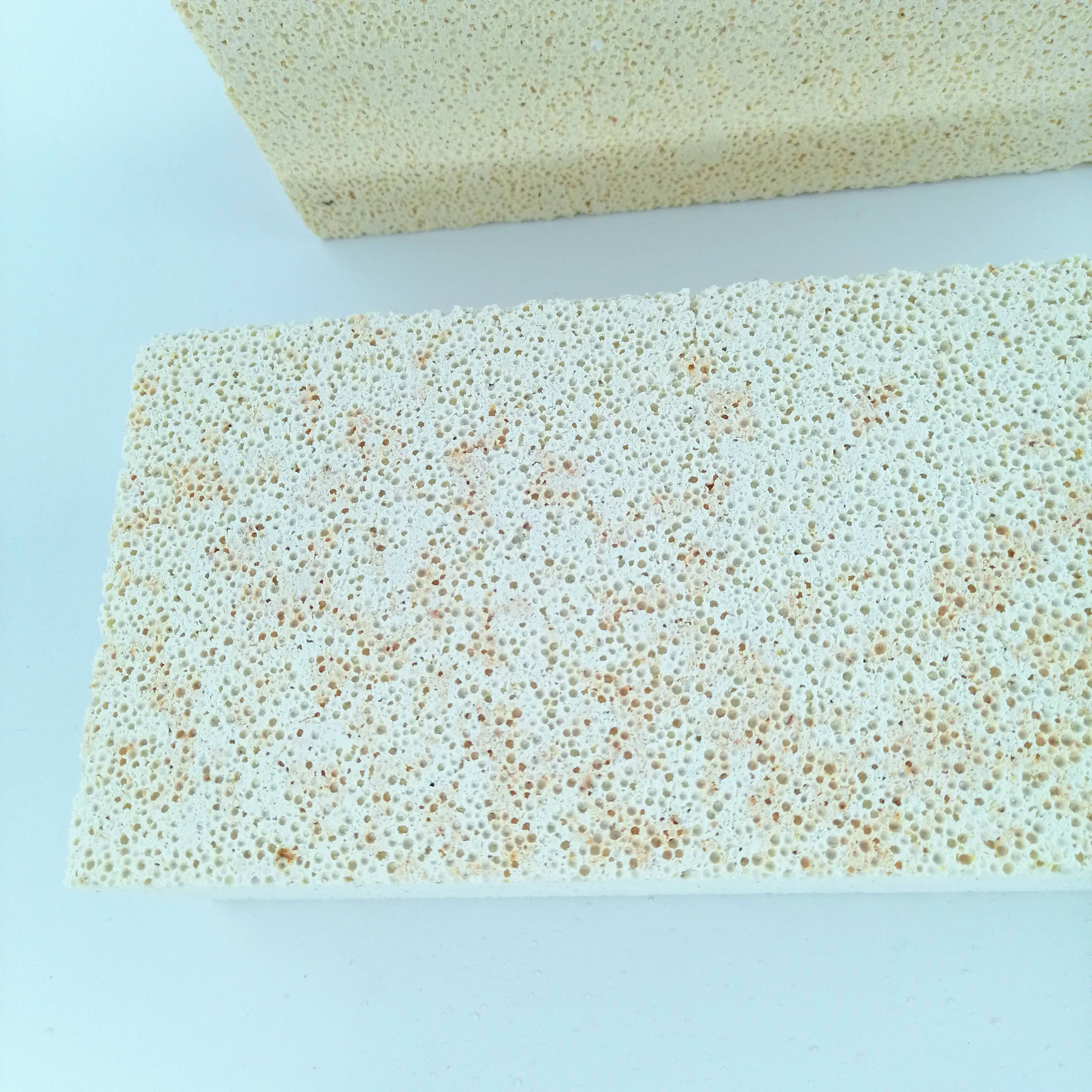

Lightweight silica insulating bricks are also called silica insulation bricks. Lightweight refractory material with silicon dioxide above 91% and bulk density below 1.2g/cm3. The refractoriness and softening temperature under load are not much different from ordinary silica bricks with the same composition. However, due to the many pores, the compressive strength, slag resistance, and corrosion resistance are not as good as ordinary silica bricks, but the thermal shock resistance has been improved.

Using finely divided silica as raw material, the critical particle size is usually no more than 1mm, and the particles smaller than 0.5mm are no less than 90%. It is prepared by adding flammable substances to the ingredients or adopting the gas generation method to form a porous structure and firing. Can also be made into unburnt products. It is mainly used for all parts of the kiln that requires heat insulation or lightening of its own weight without direct contact with the melt, free from corrosive gas, and not subject to sudden temperature changes. It is used at high temperature and cannot be in contact with alkaline refractory materials. According to different materials, the highest operating temperature is 1200~1550℃.

silica insulating brick for coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners

Silica heat-insulating refractory bricks generally use crystalline quartzite or silica sand as raw materials, and the mineral composition is: phosphorite 78% to 86%, cristobalite 13% to 15%, and quartz 4% to 7%. Add combustible materials to the ingredients, such as coke, sawdust, anthracite, carbonized rice husk, or use gas foaming to form a porous structure. Silicone heat-insulating refractory bricks are heat-insulating silicon refractory products with a SiO2 content of more than 90% and a bulk density of less than 1.2. The refractoriness and softening temperature under load are not much different from ordinary silica bricks with the same composition.

However, due to the many pores, the compressive strength, slag

resistance, and corrosion resistance are not as good as ordinary

silica bricks, but the thermal shock resistance has been improved.

It is similar to the production process of ordinary silica bricks.

Some mineralizers (CaO, Fe2O3) are added to the ingredients to

promote the conversion of quartz, and pulp waste liquid is used as

a binder to make the bricks have a certain strength. When using

coke or anthracite as combustible additives, because the ash will

be brought into Fe2O3 and Al2O3, there is no need to add iron

scales in the ingredients. When the siliceous heat-insulating

refractory bricks are fired, a strong oxidizing flame should be

maintained before 1200°C to make the additions burn out completely.

Silica insulating brick for coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners

Silica insulating bricks have the characteristics of low thermal conductivity, high load softening temperature, small residual expansion, and excellent reburning line change performance. They are suitable for industrial furnaces such as coke ovens, hot blast furnaces, glass furnaces and carbon furnaces. It is mainly used for the heat insulation layer and working layer of thermal equipment, and can be used for the heat insulation layer of various high temperature kiln equipment under high temperature conditions (≤1500℃) without contact with molten slag. This product is suitable for the heat insulation material of the silica brick lining of the high temperature hot blast stove of the large blast furnace and the heat insulation of the silica brick masonry of the glass furnace.

General light weight silica insulating bricks can be divided into

two levels: the first grade can be used in the top of the steel

rolling heating furnace and the roof of the silicate industrial

kiln, and can be directly in contact with the flame; the second

grade is used in the general industrial kiln Insulation.

Applicable to: industrial furnaces such as coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners.

Generally, the bulk density of silicon heat insulation refractory bricks is 0.9-1.1g/cm3, the compressive strength is 2.0-5.9MPa, and the thermal conductivity is 0.35-0.42W/(m·K). It has excellent fire resistance, its softening temperature under load is close to 1620℃ for dense silica bricks, with only a small residual expansion, and its thermal stability is better than dense silica bricks. Therefore, siliceous heat-insulating refractory bricks can be used for a long time under high temperature conditions (1500-1550°C) without contact with molten slag, but they are especially suitable for high-temperature hot-blast furnaces of large blast furnaces. Thermal insulation of silica brick gas.

high quality silica insulating brick for coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners

Silica insulating brick technical data:

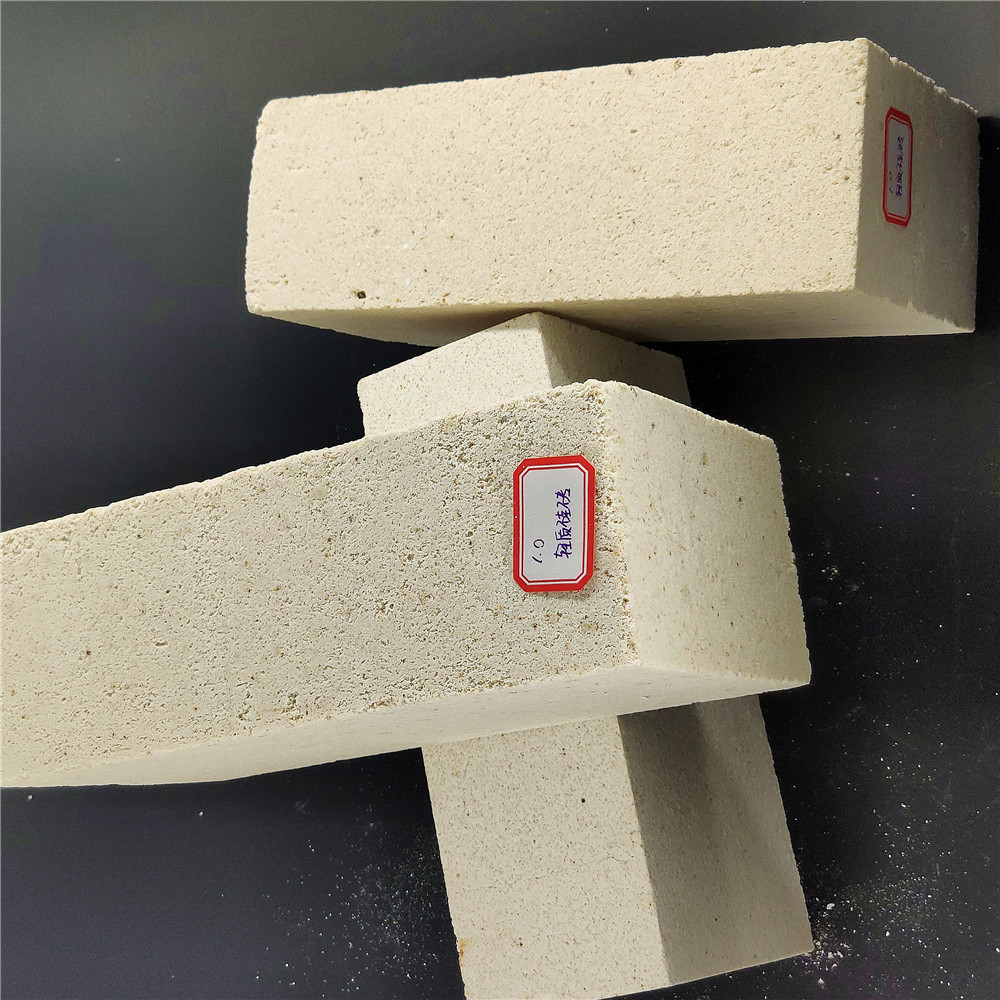

Items | GGR-1.0 | GGR-1.10 | GGR-1.15 | GGR-1.20 | |

SiO2 % ≥ | 91 | 91 | 91 | 91 | |

Bulk density g/cm3 | 1.0 | 1.10 | 1.15 | 1.20 | |

Cold crushing Strength Mpa | 2 | 3 | 5 | 5 | |

Refractoriness Under Load 0.1Mpa ≥ ℃ | 1400 | 1420 | 1500 | 1520 | |

Liner change on re-heating rate | 1550℃*2h | -- | -- | 0.5 | 0.5 |

1450℃*2h | 0.5 | 0.5 | -- | -- | |

Thermal Conductivity 350 ℃ W/(m.k) | 0.55 | 0.60 | 0.65 | 0.70 | |

| Straight | Split | Arch | Wedge | Tile | Other Shape |

| L×W×H(mm) 230×114×65 230×114×75 | L×W×H (mm) 230×114×25 230×114×32 230×114×37 230×114×50 | L×W×H/h(mm) 230×114×65/45 230×114×65/55 230×114×75/45 230×114×75/55 230×114×75/65 | L×W×H/h (mm) 230×114×65/45 230×114×65/55 220×114×75/45 220×114×75/55 220×114×75/65 | L×W×H (mm) 230×230×38 230×230×50 230×230×65 230×230×75 | Key brick, Skew brick, Soap, Checker, Neck, Taper, |

| We also can make brick according to customers' drawing and requirements. | |||||

high quality silica insulating brick for coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners

Packing for light weight silica insulating brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930 or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

Shipping of light weight silica insulating brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quality and quantity

guaranteed, and also in accordance with the contract and customer's

requirement completely.

Delivery for light weight silica insulating brick:

Delivery for light weight silica insulating brick:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample for light weight silica insulating brick:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

high quality silica insulating brick for coke ovens, hot blast furnaces, glass melting furnaces and carbon calciners

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000

tons.

3.Export experiences:

Now we have gained a global sales network reaching Taiwan,

Russia, South Korea, Vietnam, Pakistan,

Bulgaria, French, India, Egypt,Congo, Angola, South

Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

Hongtai Kiln Refractory has professional sales and after-sale service team who provide customers all-around service about product selection, transportation, installation and operation technology training etc. Now we have established cooperation relationship with many science and research units and our products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina, colombia, Eygpt, South Africa and etc.

We has over 20 years experience on producting the light weight silica

insulating brick.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.

Jerry Li

Cell&WhatsApp: 0086-13373957739

Skype: live:.cid.b12dd76d43ac731e

Email: jerry(at)firebricks-supplies.com