Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

0.5-1 Mm 1-2Mm 3-5Mm White Bubble Alumina Light Thermal Insulation Brick Hollow Ceramic Ball

The alumina bubble brick also called alumina hollow ball brick.

The anti-stripping alumina bubble brick produced by our company is made of alumina hollow balls as the main raw material, high-performance micropowder as the additive, and organic material as the temporary binder, which is fired at high temperature in a shuttle kiln. The product contains a large number of closed pores, has the characteristics of light weight, high temperature resistance, good insulation performance, small shrinkage after re-burning, and excellent thermal shock resistance. It also has strong resistance to corrosive gases and slag.

The products can greatly improve the thermal efficiency of the kiln, shorten the production cycle, reduce the weight of the kiln body, and realize energy saving and consumption reduction. Products can directly contact the flame, suitable for cracking furnaces, hot blast furnaces, heating furnaces, tunnel kilns, push kilns, crucible furnaces and various electric furnaces, electric kiln linings, widely used in metallurgy, refractories, light industry, chemical industry, Ceramics, glass, electronics and other industries. The dimensions, physical and chemical indexes, and service life of the products have reached or exceeded the level of similar products at home and abroad.

competitive price light weight Alumina bubble brick alumina hollow ball insulation brick

Physical and chemical properties of alumina hollow ball brick

Alumina hollow ball bricks have the characteristics of light

weight, high temperature resistance, good thermal insulation

performance, small shrinkage after re-fire, excellent thermal shock

resistance, etc., and also have strong resistance to corrosive

gases and slag. The products can greatly improve the thermal

efficiency of the kiln, shorten the production cycle, reduce the

weight of the kiln body, and realize energy saving and consumption

reduction.

| Item | Alumina bubble brick | Ultra purity AB | ||

| type | AB85 | AB90 | AB99 | AB99.3 |

| Max working temperature°C | 1750 | 1800 | 1800 | 1800 |

| Al2O3 % | ≥85 | ≥90 | ≥99 | ≥99.3 |

| SiO2 % | ≤15 | ≤8 | ≤0.3 | ≤0.15 |

| Fe2O3 % | ≤0.2 | ≤0.2 | ≤0.2 | ≤0.1 |

| Bulk density g/cm3 | 1.4-1.9 | 1.4-1.9 | 1.5-1.8 | 1.5-1.8 |

| Cold crushing strength MPa | ≥18 | ≥18 | ≥15 | ≥12 |

| refractoriness under load °C(0.1MPa,0.6%) | ≥1700 | ≥1700 | ≥1700 | ≥1700 |

| Reheating linear change %(1600°C×3h) | ±0.3 | ±0.25 | ±0.25 | ±0.25 |

| Thermal expansion coefficient 10-6(25-1300°C) | ~7.8 | ~8.0 | ~8.6 | ~8.6 |

| Thermal conductivity w/(m.k)(Average 800°C) | ≤0.55 | ≤0.6 | ≤0.75 | ≤0.55 |

Advantages of alumina hollow ball brick

Obvious effects will be achieved for reducing the weight of the

furnace body, transforming the structure, saving materials, and

saving energy.

1. High operating temperature:

It can reach above 1750 degrees, with good thermal stability. The

reheating line has a small change rate and can be used for a longer

time.

2. Optimize the structure and reduce the weight of the furnace

body:

The bulk density of heavy bricks currently used with high

temperature resistant materials is 2.6-3.0g/cm3, while alumina

hollow ball bricks are only 1.3~1.5g/cm3. For the same volume of

one cubic meter, the use of alumina hollow ball bricks can reduce

1.1- 1.7 tons weight.

3. Save materials:

To reach the same operating temperature, the price of heavy bricks

is equivalent to that of alumina hollow ball bricks, and

considerable refractory materials are required for insulation. If

alumina hollow ball bricks are used, 1.1-1.9 tons of heavy bricks

can be saved per cubic meter, and 80% of refractory insulation

materials can be saved.

4. Save energy:

Alumina hollow spheres have obvious thermal insulation properties

and low thermal conductivity, which can achieve a good thermal

insulation effect, reduce heat dissipation, improve thermal

efficiency, and save energy. The energy saving effect can reach

more than 30%.

competitive price light weight Alumina bubble brick alumina hollow

ball insulation brick

Alumina hollow ball bricks are mainly used as the lining of high-temperature industrial kilns below 1800°C, such as high-temperature kiln lining bricks in the refractory, electronics, and ceramic industries; thermal insulation for high-temperature thermal equipment, such as the petrochemical industry Insulation bricks for gasifiers, gas generators, carbon black industrial reactors, and induction furnaces in the metallurgical industry. Application in the above-mentioned fields can save energy by 20% to 30%. This kind of brick is used as the lining of high-temperature kiln, the heating speed should not be too fast during baking, otherwise it will produce cracks, reduce the strength and service life; because of its high apparent porosity, it can not be used in the parts contacting the slag, otherwise it will Damaged by slag penetration.

Alumina hollow ball bricks can be used for high-temperature energy-saving inverted flame kilns, shuttle kilns, molybdenum wire furnaces, tungsten rod furnaces, induction furnaces, nitriding furnaces, etc. Obvious effects will be achieved for reducing the weight of the furnace body, transforming the structure, saving materials, and saving energy.

competitive price light weight Alumina bubble brick alumina hollow

ball insulation brick

The preparation of alumina hollow ball bricks takes industrial alumina as raw material, melted by electric fusion method, and sprayed. The electric melting equipment is an electric arc furnace. The molten pool is made of graphite products or other refractory materials, with an orifice built on the edge, and a nozzle for compressed air is installed outside the orifice. The nozzle is connected to the compressed air device by a pipe; the furnace body can be tilted; the electrode is made of graphite.

After adding industrial alumina powder in the molten pool, it can

be melted by electricity. When the temperature of the molten liquid

reaches or higher than 2200°C, the molten liquid rolls, that is,

the furnace body is tilted to make the molten liquid flow out; at

the same time, the molten liquid stream is sprayed with compressed

air Due to the effect of melt viscosity and surface tension, the

melt forms hollow spheres enveloping air during the blowing and

condensation process, which are collected and screened, and stored

separately according to different particles for later use.

The ratio of the number of hollow alumina spheres with different

particle sizes varies with the compressed air injection pressure.

The greater the pressure, the greater the number of small spheres.

The wall thickness of the hollow sphere varies with the particle

size. When the particle size fluctuates in the range of 5 to 0.5

mm, the wall thickness fluctuates in the range of 0.3 to 0.1 mm.

The larger the particle size of the hollow sphere, the smaller its

natural packing density; the smaller the particle size, the larger

its natural packing density. For example: when the particle size is

5.13~3.22mm, the natural bulk density is 470g/L; when 3.22~2.0mm,

670g/L; when 2.0~1.0mm, 810g/L; 1.0 At ~0.5mm, 915g/L.

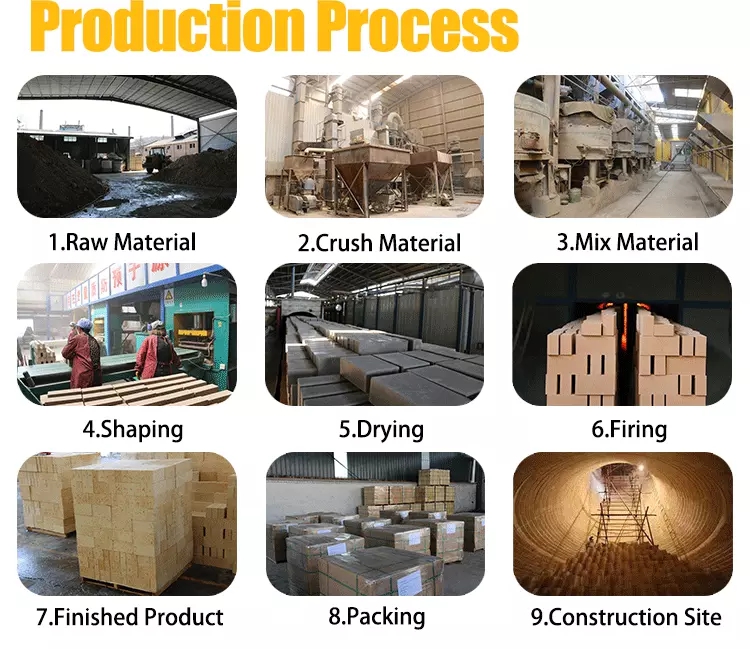

Manufacture of alumina hollow ball bricks The alumina hollow ball,

sintered alumina fine powder and binder are mixed in a certain

proportion, formed, dried, and fired to prepare alumina hollow ball

bricks.

Alumina fine powder is made from industrial alumina as raw

material, calcined at 1500°C, then ground, pickled and dried.

The bonding agent used in making bricks is usually aluminum sulfate

aqueous solution or aluminum dihydrogen phosphate aqueous solution.

Alumina hollow spheres generally have a particle size of 5 to 0.5

mm, the amount is 65% to 70%, the amount of fine alumina powder is

30% to 35%, and the amount of binder is 5%.

Mix the above-mentioned materials uniformly and form them by

vibration molding method. After the bricks are dried, they are

fired at 1500 to 1800°C to make fired bricks; they can also be made

without firing to make unfired products, or the furnace lining can

be directly constructed with unshaped materials.

competitive price light weight Alumina bubble brick alumina hollow ball brick

Packaging for light weight Alumina bubble brick alumina hollow ball brick

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard brick),but 1*1m (special shape brick) at most,

(2)Load weight of each pallet:Usually 1.2-1.5Tons, max 2.0 Tons.

(3)20 Foot Container can be loaded max 25-26Tons, about 13-21Pallets.

2.Can make the package according to customer's requirements.

Shipping for light weight Alumina bubble brick alumina hollow ball brick

1.FEDEX/DHL/UPS/TNT for samples.

2.By Sea for batch goods.

3.Customers specifying freight forwarders or negotiable shipping methods!

4.Delivery Time for light weight Alumina bubble brick alumina hollow ball brick:

(1)Samples:3 days for common shape samples;15 days for special shape samples.

(2)Batch goods:Within 7-10days for in stock bricks from ordering shipping space to deliver goods and within20-30 days for NO in stock bricks.

Payment Terms

(1)T/T, Western Union,LC;

(2)Usually 30% deposits,70% balance to be paid before delivery or against copy of BL or negotiations

Others

MOQ: Usually 1 container, MOQ 1Tons, Customers can order certain PCS for special brick.

competitive price light weight Alumina bubble brick alumina hollow ball brick

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and certification. And the annual supply of shaped

and unshaped refractory product is 28, 800-35, 000 tons.

3. Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

South Korea, Vietnam, Pakistan, Bulgaria, French, India, Congo,

Angola, South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester Bulk Density Tester The Pressure Tester Refractoriness Tester

Hongtai Kiln Refractory has professional sales and after-sale service team who provide customers all-around service about product selection, transportation, installation and operation technology training etc. Now we have established cooperation relationship with many science and research units and our products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina, colombia, Eygpt, South Africa and etc.

We has over 20 years experience on producing the competitive price light

weight Alumina bubble brick alumina hollow ball insulation brick.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.