Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

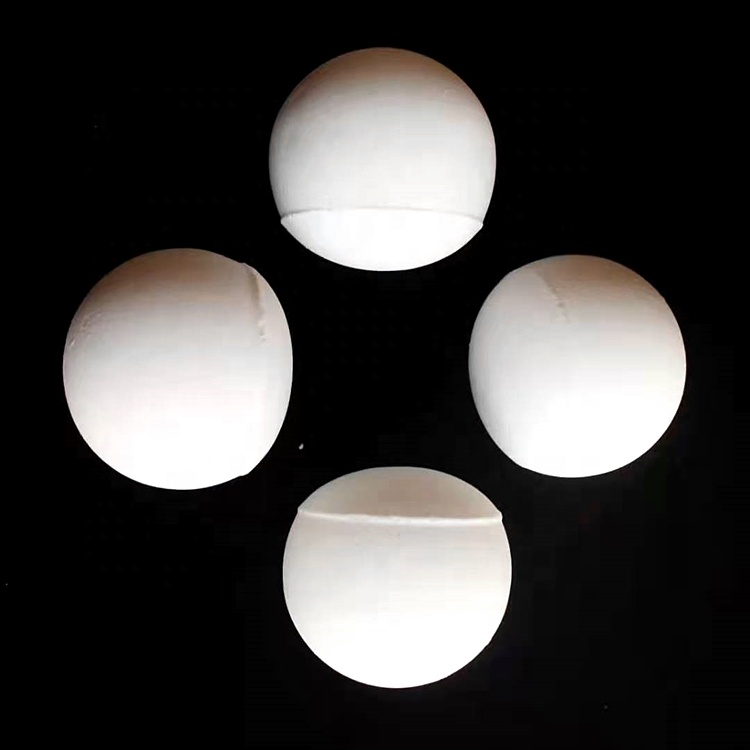

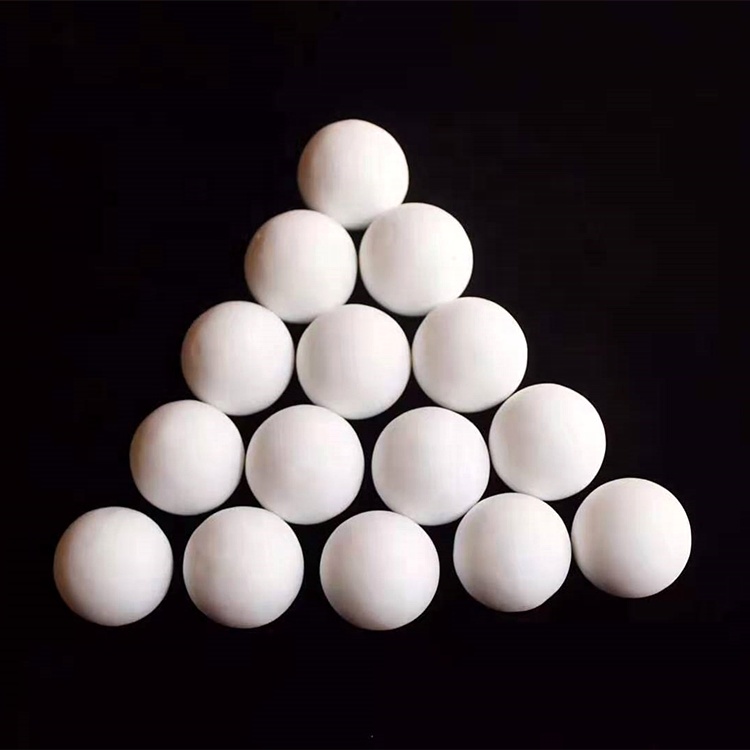

Al2o3 Tio2 Sio2 Ball Used In Ceramics Industries Refractory Material Dia 6Mm

Alumina ceramic ball is an important engineering ceramic, which is

a high-tech product. Due to the characteristics of suitable

hardness, moderate density, wear resistance, corrosion resistance,

low price, and the introduction of metal impurities from metal

balls, alumina ceramic balls are widely used in white cement,

minerals, ceramics, electronic materials, and magnetic materials As

well as the grinding and processing of raw materials in paint,

paint and other industries, it is a high-quality grinding medium.

In the building ceramic industry, the wear efficiency of alumina

ceramic balls is higher than that of natural flint and pebbles.

With the reduction of high-quality natural ball resources and the

high wear rate of ordinary ceramic balls, alumina ceramic balls

will be used by more and more ceramic manufacturers. According to

different alumina content, it can be divided into medium aluminum

balls, medium high aluminum balls and high aluminum balls.

Generally, we classify 60%-65% alumina content as medium aluminum

balls, and 75%—80% alumina content is called Medium and high

alumina balls, with more than 90% alumina content are high alumina

balls. Among them, the high alumina ball is subdivided into 90

porcelain, 92 porcelain, 95 porcelain and 99 porcelain. Due to its

extremely high production cost, few large-scale manufacturers

manufacture 99 porcelain in large quantities, and it is mainly made

by hand by some special ceramic factories.

Medium aluminum balls and medium-high aluminum balls are accepted

by most ceramic factories due to their lower prices and are mainly

used for grinding ceramic blanks. High aluminum balls are widely

used in different types of ceramics, enamels, glass, and chemicals

due to their high strength, high hardness, high wear resistance,

high specificity, small size, high temperature resistance,

corrosion resistance, and pollution-free properties. For the

finishing and deep processing of thick and hard materials in

factories, especially high-aluminum balls with 92 content are most

commonly used.

Al2o3 Tio2 Sio2 Ball Used In Ceramics Industries Refractory Material Dia 6Mm

The wear mechanism of alumina ceramic balls are divided into brittle fracture wear and plastic deformation wear. The wear characteristic of the former is the shedding of grains along the crystal fracture, and the wear characteristic of the latter is the microcutting of transgranular fracture. The wear rate of the former is much greater than that of the latter. It is hoped that the wear of ceramics is plastic deformation wear. The internal factors of ceramics have an important influence on the plastic deformation and wear mechanism of ceramics. Alumina ceramic balls are a kind of friction and wear components, and their wear rate is affected by internal and external factors, of which internal factors have a greater impact. The wear resistance of alumina ceramics is closely related to the mechanical properties of its own materials and the synergy of the microstructure, that is, its internal factors, elastic modulus, hardness, fracture toughness, grain size, grain boundaries and porosity. People have conducted a lot of research on this. The toughness and grain size of ceramics are the most studied internal factors and are most closely related to the wear resistance. Toughness has a great influence on the friction and wear of ceramics. The better the abrasiveness, so wear-resistant ceramics are developing in the direction of microcrystallization. However, the cost of nano alumina ceramics is very high, and it is difficult to popularize and use in the field of engineering applications. Therefore, the research focus of alumina ceramic wear-resistant materials has made breakthroughs and developments in the grain size range of several microns.

Al2o3 Tio2 Sio2 Ball Used In Ceramics Industries Refractory Material Dia 6Mm

Items | Technical Data | ||||

High Alumina ball | Modified High Alumina | High Alumina High Density | High Density Low Creep | ||

Al2O3 | % | 55 | 65-75 | 70 | 70-80 |

Fe2O3 | % | 2 | 1.8 | 1.8 | 1.8 |

Refractoriness | °C | 1750 | 1770 | 1790 | 1790 |

Apparent porosity | % | 26 | 25 | 24 | 20 |

Bulk Density | g/cm ³ | 2.35 | 2.35 | 2.6 | 2.75 |

Cold Crushing strength | Mpa | 10 | 11 | 12 | 13 |

Refractoriness Under Load of 0.2Mpa | °C | 1420 | 1450 | 1480 | 1520 |

Supply high-strength proppant fillers for alumina ceramic balls

Packaging of alumina ceramic balls

1. 1 ton bags in container, 25 MT/20'FCL.

2. 25kg bags in container, 25 MT/20'FCL

3. 25kg bags in ton bags, then in container, 25 MT/20'FCL

4. as the customer' request

Shipping of alumina ceramic balls

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quality and quantity

guaranteed, and also in accordance with the contract and customer's

requirement completely.

Delivery for alumina ceramic balls:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Alumina ceramic balls Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Alumina ceramic balls Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods.

Your inquiry related to our alumina ceramic balls product & price will be replied within 24 hours.

Export:

Our alumina ceramic balls products have been exported to many countries: Australia, Chile,

USA, Russia, UK, Indonesia, etc., good quality have be approved by

our clients.

Supply high-strength proppant fillers for alumina ceramic balls

Supply high-strength proppant fillers for alumina ceramic balls

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers, which can be summarized in four aspects: reliable quality, timely delivery, reasonable price and considerate service.The company will continue to adhere to the corporate spirit of "contributing to society and serving customers" and the business philosophy of "mutual benefit, win-win, integrity, efficiency, preciseness and responsibility".Our company is willing to develop a wide range of technical exchanges with colleges and universities and colleagues from all walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.For different industries, the cement industry with anti-flaking high-alumina bricks, alkali resistant bricks, phosphate bricks;Boiler industry USES all kinds of brand wear-resisting brick, corundum brick, mullite brick and other finalizing materials.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our aim."Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service.Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.

Al2o3 Tio2 Sio2 Ball Used In Ceramics Industries Refractory Material Dia 6Mm

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000

tons.

3. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

4. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester Bulk Density Tester

The Pressure Tester Refractoriness Tester

Supply high-strength proppant fillers for alumina ceramic balls

1.Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

2.Free sample of dry ramming mass

Sample and trial order are accepted for the quality evaluation

3.Strict quality control

Arrange production on time and control quality strictly.

4.Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5.Professional Services

Provide all the detailed news and pictures from order to delivery;offer relative export documents and original certificate if needed;warm and considerable after-sale service.

Hongtai Kiln Refractory has professional sales and after-sale service team who provide customers all-around service about product selection, transportation, installation and operation technology training etc. Now we have established cooperation relationship with many science and research units and our products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina, colombia, Egypt, South Africa and etc.

We has over 20 years experience on producing alumina ceramic balls.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.