Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

High quality high zirconia ramming mass for glass melting furnace

Zirconia ramming mass

Zirconia ramming mass is an unshaped refractory material, which has the characteristics of strong fluidity and easy operation and construction. It is made up of melted corundum aggregate particles and a small amount of additives. This product has the characteristics of easy to use, hardening at room temperature, high compressive strength at high temperature, low thermal expansion and shrinkage, strong resistance to solution corrosion, etc. It is the most ideal unshaped refractory material for glass and frit tank kiln sealing layer.

The zirconium ramming mass is made of high-quality zirconium moss bone, powder, aluminum phosphate as the binder and admixture, and is formulated in a good proportion. It has low high-temperature thermal conductivity, good thermal shock resistance, and chemical stability. Molten glass and liquid metal have good corrosion resistance, work stably in an oxidizing atmosphere, and do not chemically react with molten metal. It is an excellent thermohardened amorphous refractory. It is widely used in the field of glass furnace bottom, ladle and circulating fluidized bed boiler.

High quality high zirconia ramming mass for glass melting furnace

Item | Behaviors | |||

AZSR-50V ERSOL 50 | AZSM-06J ERSOL 06 | AZSM-05 ERSOL 05 | ||

Chemical Composition | Al2O3 | 48 | 48 | 48 |

ZrO2 | 30 | 30 | 30 | |

SiO2 | 20 | 20 | 20 | |

Others | 2 | 2 | 2 | |

Bulk density g/cm3 | 3.2 | 3.1 | 3.1 | |

Crystallographic analysis after being sintered at 1300/1500°C | Corundum, zirconium oxide | Corundum, zirconium oxide | Corundum, zirconium oxide | |

Thermal conductivity | Good | Good | Good | |

Anti-corrosion property | Excellent at 1300°C | Excellent at 1300°C | Excellent at 1300°C | |

particle diameter of grain | 0-5mm | 0-0.6mm | 0-0.5mm | |

Application temperature | Cold/low temperature | Cold/low temperature | Cold/low temperature | |

Quantity of water | 8-10% (proportion by weight) | 10-12% (proportion by weight) | 10-12% (proportion by weight) | |

Solidification | Water (ceramic) | Water (ceramic) | Water (ceramic) | |

Packaging | 25kg/bag | 25kg/bag | 25kg/bag | |

Quality guarantee period | 12 months | 12 months | 12 months | |

Used for | Under bottom paving, spreading, Melting end and working area | Under bottom paving, spreading and the place between fused cast brick | Under bottom paving, spreading, and the joint between bricks of two layers that are between the fused cast brick | |

Note: Above mentioned indexes allow few deviation for special demanded products.

High quality high zirconia ramming mass for glass melting furnace

Zirconia ramming mass production procedure:

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of brick again in factory.

zirconia raming mass usage:

1. concreting time: beginning time: 0:15~2:00 hours

2. finishing time: 3:00~6:00 hours

3. heating time: after 150:00 hours

4. this material is without phosphorus,and does not pollute the

enviroment.

High quality high zirconia ramming mass for glass melting furnace

Henan Hongtai Kiln Refractory Co., Ltd. is established in 2005 and located in Xinmi city, 40 kilometers southwest of Zhengzhou city. Rich resources of refractory materials, adequate and qualified fuel in this area, provide unique conditions for refractory production.

Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our aim."Scientific management, strong technical force, perfect testing means, advanced technological equipment and stable product quality are the guarantee of quality service.Henan hongtai kiln refractories co., LTD sincerely hopes to cooperate with you hand in hand and in good faith.

High quality high zirconia ramming mass for glass melting furnace

The zirconia ramming mass and castable product refers to an amorphous product that is pre-laid at the working temperature/ceramic bonding.

Hongtai has developed a range of integrated products that are a by-product of the electrofusion line and the sintering line. These monolithic products are mainly used in:

- Safety layer for the bottom and the channel

- Cold repair/hot repair special application security layer

- Mud between different refractory materials or brick joints

High quality high zirconia ramming mass for glass melting furnace

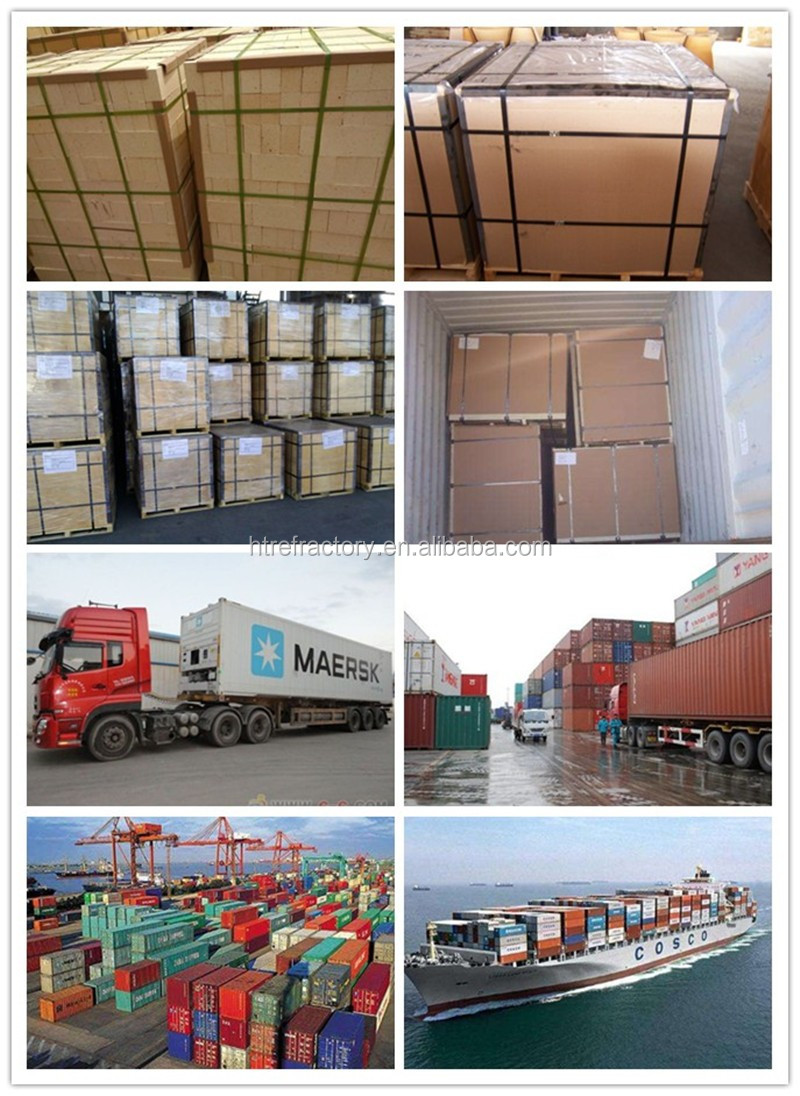

Packaging & Shipping for zirconia ramming mass

High temperature resistance glass kiln used zirconia ramming mass are packaged with fumigated wooden pallet, using paper or

non-woven fabrics between layers separated,plastic shrink film

protected outside.finally using straps. Or as your requirements.

Delivery for zirconia ramming mass:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample for zirconia ramming mass:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order:

Usually by sea.Payment: It can be through T/T, L/C at sight. The

specific terms determined according to the quantity of the goods,

etc.

Your inquiry related to our zirconia ramming mass product & price will be replied within 24 hours.

Export:

Our zirconia ramming mass products have been exported to many countries: Australia, Chile,

USA, Russia, UK, Indonesia, etc., good quality have be approved by

our clients.

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)firebricks-supplies.com