Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

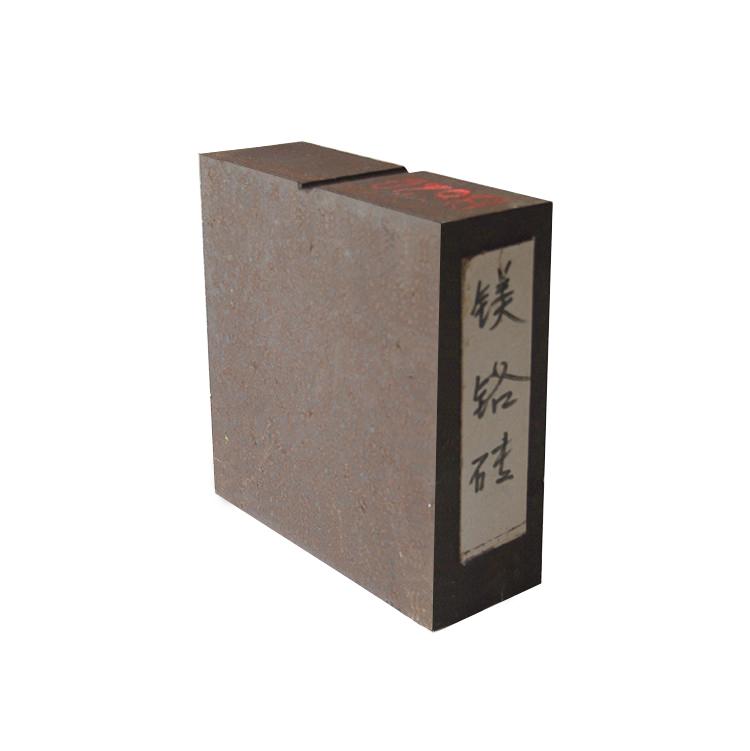

Henan Hongtai refractory kiln factory supply Sintered MZ or Fused

DMZ Megnesia bricks for glass melting Horseshoe Flame Kiln

The magnesia content of magnesia bricks is 90%-98%. The main products are dead-burned magnesite bricks, middle-grade magnesire bricks, high-purity magnesite bricks, fused magnesite bricks, and alkaline refractories with magnesia as the main crystal phase.

Magnesia bricks have high refractoriness. Sintered magnesia bricks use brick magnesia as raw materials. After crushing, batching, kneading, and molding, they are fired at a high temperature of 1550~1600℃. The firing temperature of high-purity products is at Above 1750℃. Unburned magnesire bricks are made by adding appropriate chemical binders to magnesia, after mixing, molding, and drying.

Henan Hongtai refractory kiln factory supply Sintered MZ or Fused

DMZ Megnesia bricks for glass melting Horseshoe Flame Kiln

The refractoriness of magnesia bricks can reach more than 2000 ℃, and the softening temperature under load varies greatly with the melting point of the cementitious phase and the amount of liquid phase produced at high temperature. Generally, the starting temperature of load softening of magnesia brick is between 1520~1600℃, while that of high-purity magnesia brick can reach 1800℃. The load softening start temperature of magnesia brick is not much different from the collapse temperature. The linear expansion rate of magnesia brick at 20~1000℃ is generally 1.2%~1.4%, and it is approximately linear.

When a liquid phase appears in the brick at high temperatures, it shrinks suddenly. The thermal conductivity of magnesia bricks is higher, second only to carbon bricks and silicon carbide bricks in refractory products, and it decreases with the increase of temperature.

The typical physical and chemical properties of various magnesia bricks:

| Type | Main composition(%) | AP(%)≤ | B.D | CCS | RUL(℃) ≥ | TSR | |||

| MgO(%)≥ | SiO2(%)≤ | CaO(%)≥ | (g/cm3)≥ | Mpa≥ | 1100℃≥ | ||||

| Sintered magnesia brick | MZ-90 | 90 | 3.5 | 3 | 20 | 2.9 | 50 | 1500 | 10 |

| MZ-92 | 92 | 3 | 2.5 | 18 | 2.92 | 55 | 1550 | 10 | |

| MZ-95 | 95 | 2.5 | 2 | 18 | 2.95 | 60 | 1600 | 10 | |

| MZ-97 | 97 | 1.2 | 1.5 | 17 | 3 | 70 | 1650 | 10 | |

| Fused magnesia brick | DMZ-96 | 95.5 | 2 | 1.5 | 17 | 2.95 | 65 | 1600 | 8 |

| DMZ-97B | 96.5 | 1.5 | 1.2 | 16 | 3.05 | 70 | 1700 | 8 | |

| DMZ-97A | 96.8 | 1.5 | 1.2 | 16 | 3.1 | 70 | 1700 | 8 | |

| DMZ-98B | 97.3 | 1.2 | 1.2 | 15 | 3.1 | 80 | 1700 | 8 | |

| DMZ-98A | 97.5 | 1 | 1.2 | 15 | 3.15 | 80 | 1700 | 8 | |

Henan Hongtai refractory kiln factory supply Sintered MZ or Fused DMZ Megnesia bricks for glass melting Horseshoe Flame Kiln

Magnesia brick production process:

The magnesia raw material is crushed into granules and powders, and after mixing according to a certain proportion, the binder is added and mixed to form a mud, and then formed into a fired magnesia brick through processes such as forming, drying and firing. The firing temperature of ordinary magnesia bricks is generally 1500~1650℃, and the firing temperature of high-purity magnesia bricks is as high as 1700~1900℃. The production process of chemically bonded magnesia bricks is basically the same, except that the chemical bonding agent is combined without high-temperature firing, and only proper low-temperature heat treatment is needed to make unburned magnesia bricks.

The main usage of magnesia brick:

Magnesia brick application

1. Alkaline open hearth furnace for steelmaking

2. Electric furnace bottom and furnace wall

3. Oxygen conversion lining

4. Non-ferrous metal metallurgy furnace

5. High temperature tunnel kiln

6. Cement rotary kiln lining

7. Heating furnace bottom and furnace wall

8. Regenerator of glass melting furnace

Henan Hongtai refractory kiln factory supply Sintered MZ or Fused DMZ Megnesia bricks for glass melting Horseshoe Flame Kiln

Magnesia carbon brick Magnesia chrome brick

Magnesia alumina spinel brick Silica brick

Silica mullite brick Light weight silica brick

Henan Hongtai refractory kiln factory supply Sintered MZ or Fused DMZ Megnesia bricks for glass melting Horseshoe Flame Kiln

Packaging for magnesia brick

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel

belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard brick),but 1*1m

(special shape brick) at most,

(2)Load weight of each pallet:Usually 1.5-1.7Tons, max 2.0 Tons.

(3)20 Foot Container can be loaded max 25-26Tons, about

13-16Pallets.

2.Can make the magnesia brick package according to customer's requirements.

Shipping for magnesia brick

1.FEDEX/DHL/UPS/TNT for samples.

2.By Sea for batch goods.

3.Customers specifying freight forwarders or negotiable shipping

methods!

4.Delivery Time of magnesia brick:

(1)Magnesia brick Samples:3 days for common shape samples;15 days

for special shape samples.

(2)Batch goods:Within 7-10 days for in stock magnesia bricks from

ordering shipping space to deliver goods and within 20-30 days for

NO in stock magnesia bricks.

Our company:

Henan Hongtai Kiln refractory is an independent manufacturer of refractories, heat resistant products and high temperature insulation materials which follows the tradition of refractory and heat resistant manufacturing in Xinmi, Henan, since 2002.

Our products include fire cement, fire bricks, refractory setting cements/mortars, plastic mouldables refractories, high alumina refractory products, zirconia refractory products, magnesite refractory products, silica refractory products, carbon refractory products, silicon carbide refractory products, acid resistant cements and refractory castables for use in industries including steel plants, heat and power stations, foundries both ferrous and non-ferrous, cement producers, lime producers, glass works, ceramics, coke plants, incinerators, renewable energy, chemical works, sugar refineries and petrochemical industry.

Our service:

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractories

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000 tons.

3. Production equipment:

Production and testing equipment are new, complete and automated or

semi- automated. Such modern facilities and equipment have provided

the fine technical guarantee for the production and testing.

4. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester Bulk Density Tester The Pressure Tester

Refractoriness Tester

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)ht-refractory.com