Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Cement production kiln using magnesia alumina spinel curved refractory fire bricks

Magnesia Alumina Spinel Bricks are new developed chrome-free refractories for Cement Rotary Kilns, with excellent performance,our products have been wide used in the domestic and overseas cement projects.

Cement production kiln using magnesia alumina spinel curved refractory fire bricks

Description of Magnesia Alumina Spinel Brick

1.Outstanding resistance to chemical attack

2.Outstanding thermal-shock resistance

3.Highest refractoriness

4.Excellent abrasion resistance

5.Excellent performance under thermal and mechanical loads

Advantage of Magnesia Alumina Spinel Brick

Form A

Guarantee/Warranty

Packaging

Price

Product Features

Product Performance

Prompt Delivery

Quality Approvals

Reputation

Service

Small Orders Accepted

Cement production kiln using magnesia alumina spinel curved refractory fire bricks

Chemical & Physical Data Of Magnesia Alumina Spinel Brick

index item | magnesia-alumina brick | magnesia-alumina spinel brick | Periclase-spinel brick | high-purity mag-alumina brick | ||||

| ML-80A | ML-808 | LMJ-A | LMJ-C | LMJ-C | LPJ-80A | LPJ-80B | LCML-86 | |

| MgO% | 80 | 80 | 80 | 75 | 70 | 82 | 80 | 86 |

| AL2O3% | 5~10 | 5~10 | 8~15 | 8~15 | 8~15 | 5~10 | 5~10 | 5~10 |

| 0.2MPa refractoriness under load 0C ≥ | 1600 | 1580 | 1700 | 1650 | 1600 | 1620 | 1600 | 1700 |

| cold crushing strength MPa ≥ | 45 | 40 | 35 | 35 | 35 | 39.2 | 39.2 | 35 |

| apparent porosity % ≤ | 18 | 20 | 17 | 18 | 19 | 18 | 18 | 16 |

| thermal shock resistance (11000C-water) times ≥ | 20 | 15 | 10 | 7 | 5 | |||

Cement production kiln using magnesia alumina spinel curved refractory fire bricks

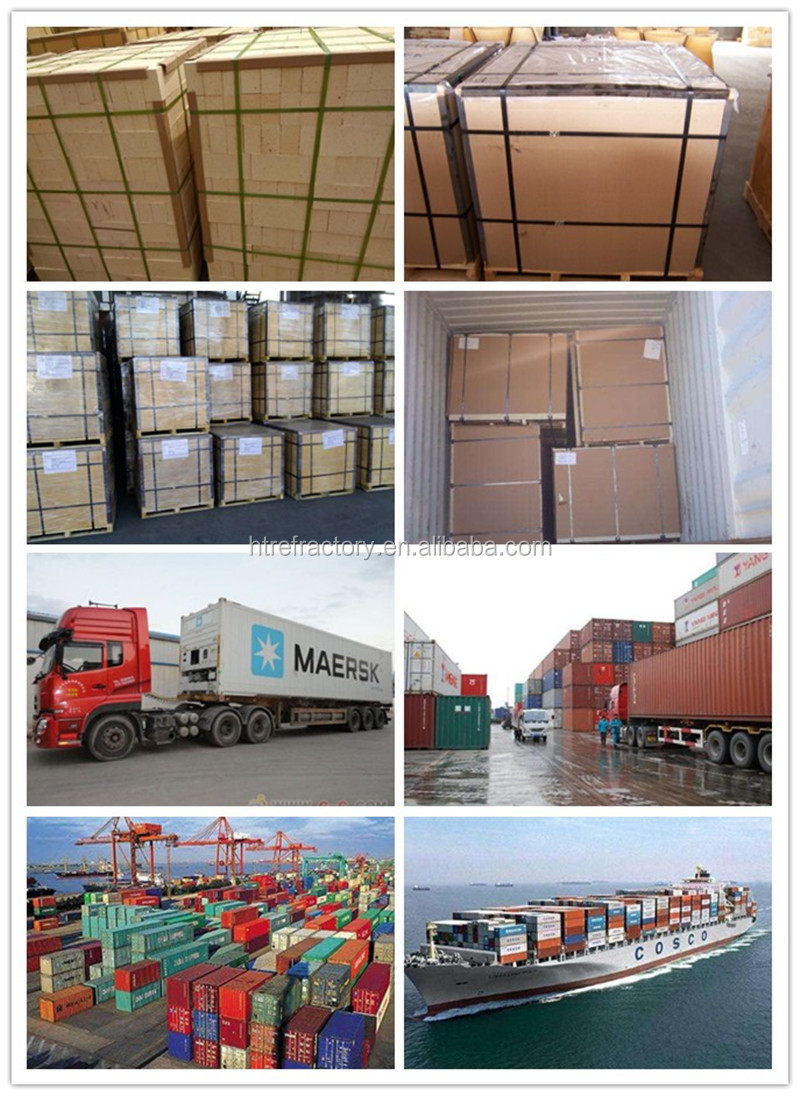

Packaging of Magnesia Alumina Spinel Brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of Magnesia Alumina Spinel Brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

Cement production kiln using magnesia alumina spinel curved refractory fire bricks

Cement production kiln using magnesia alumina spinel curved refractory fire bricks

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of Magnesia Alumina Spinel Brick

again in factory.

Cement production kiln using magnesia alumina spinel curved refractory fire bricks