Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

China refractory manufacturer factory supply high alumina

refractory brick price tons for steel and iron industries

High alumina refractory brick price tons for steel and iron industries, that is, alumina content in 48% or more of an aluminum silicate refractory. Made of bauxite or other raw materials of higher alumina content after molding and calcining. High thermal stability, refractoriness above 1770℃. Good slag resistance.

High alumina lining bricks can be classified according to its mineral composition, generally divided into five categories: low Mullite (silystone), Mullite, Mullite-corundum corundum - mullite and corundum.

The high alumina lining bricks usually divided into three categories:

Ⅰ: Al2O3 content of 75% or more;

Ⅱ: Al2O3 content is 60% ~ 75%;

Ⅲ: Al2O3 content is 48% ~ 60%;

One of the important properties of high alumina lining brick is its structural strength at high temperature. The high temperature creep is also measured to reflect the high temperature structural strength. The results show that the softening temperature of load increases with the increase of Al2O3 content.

For high alumina blining ricks with Al2O3 content below 70%, the softening temperature under load depends on the amount ratio between the crystalline and liquid phases, which increases with the increase of the amount of mullite. The quantity and properties of liquid phase have obvious influence on the softening temperature under load. Therefore, reducing the content of impurities in the raw material is conducive to improving the softening temperature of load and high-temperature creep.

Application of High Alumina Bricks

It is mainly used for lining of blast furnace, hot blast furnace, electric furnace top, blast furnace, reverberatory furnace and rotary kiln. In addition, high alumina firebrick is widely used as open hearth grate brick of regenerative type, plug head of pouring system, nozzle brick and so on.

The weight of heavy high aluminum brick, also called high aluminum brick, is many times heavier than that of light high aluminum brick. In the process of use, it is not for heat insulation and heat preservation, but more importantly for fire-resistant temperature. It is usually in direct contact with the flame in the kiln during use, so heavy high aluminum brick usually has the function of high temperature resistance. Select high bauxite clinker combined with refractory clay, according to the multi-stage batching, press molding, high temperature burning. The high alumina brick is divided into three grades according to the alumina content. The alumina content and high temperature resistance of the high alumina brick are guaranteed by adjusting the ratio of high alumina clay to the combined clay.

China refractory manufacturer factory supply high alumina refractory brick price tons for steel and iron industries

High alumina lining brick technical data:

Items | Technical Data | ||||

International code name | SK35 | SK36 | SK37 | SK38 | SK40 |

Chinese code name | LZ-48 | LZ-55 | LZ-65 | LZ-75 | LZ-80 |

Al2O3 min % | 48 | 55 | 65 | 75 | 80 |

Fe2O3 max % | 2 | 2 | 2 | 2 | 2 |

Refractoriness ℃min. | 1750 | 1770 | 1790 | 1790 | 1790 |

Refractoriness under Load C min. | 1420 | 1470 | 1500 | 1520 | 1530 |

Permanent Linear Change % | 1450 C×2h | 1500 C×2h | 1500 C×2h | 1500 C×2h | 1500 C×2h |

+0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | +0.1~-0.4 | |

Apparent Porosity max. % | 22 | 22 | 23 | 23 | 21 |

Cold Crushing Strength mim. | 39 | 44 | 49 | 54 | 65 |

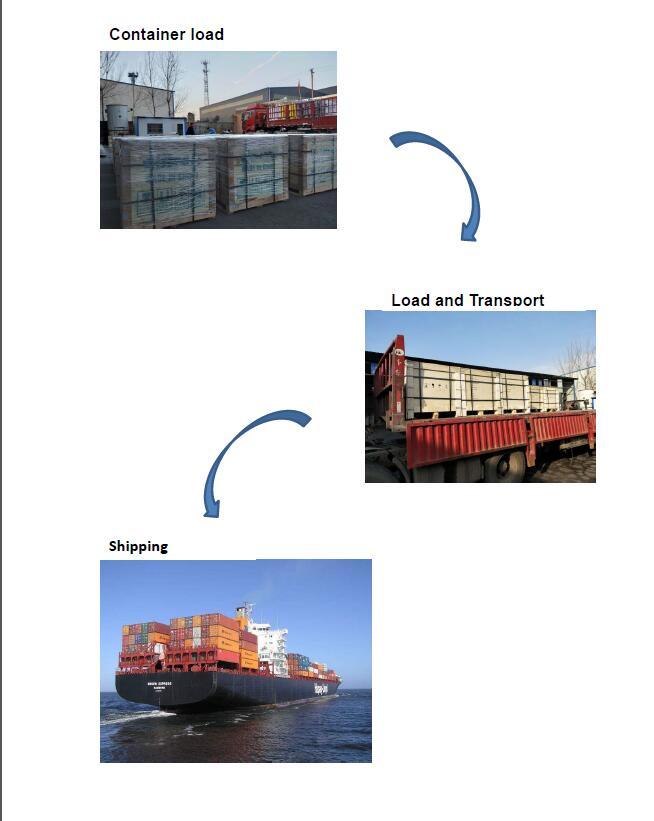

Packaging of High Alumina Lining Brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

Shipping of High Alumina Lining Brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quality and quantity

guaranteed, and also in accordance with the contract and customer's

requirement completely.

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers, which can be summarized in four aspects: reliable quality, timely delivery, reasonable price and considerate service.The company will continue to adhere to the corporate spirit of "contributing to society and serving customers" and the business philosophy of "mutual benefit, win-win, integrity, efficiency, preciseness and responsibility".

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring material, corundum pouring material, low cement high strength pouring material, impermeable material, self-flowing material, plastic material, and various types of refractory materials.

Our competitive Advantage for high alumia lining brick:

1.Competitive Price. Make the products competitive in your market.

2.Quick Response:We promise quick response at the very first moment when we received your request. 3.Superior Customer Service:The company provides after sales service ensuring customer’s satisfactions,we believe in Long term partnership bringing loyalty.

4.We had been on this filed for many years and we have our own research team,the prouduction process could be concrolled strictly.

5.We have developed stable customer base overseas and kept long-term cooperation.

Hongtai Kiln Refractory has professional sales and after-sale

service team who provide customers all-around service about product

selection, transportation, installation and operation technology

training etc. Now we have established cooperation relationship with

many science and research units and our products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina,

colombia, Egypt, South Africa and etc.

We has over 20 years experience on producing high alumina brick.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.