Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

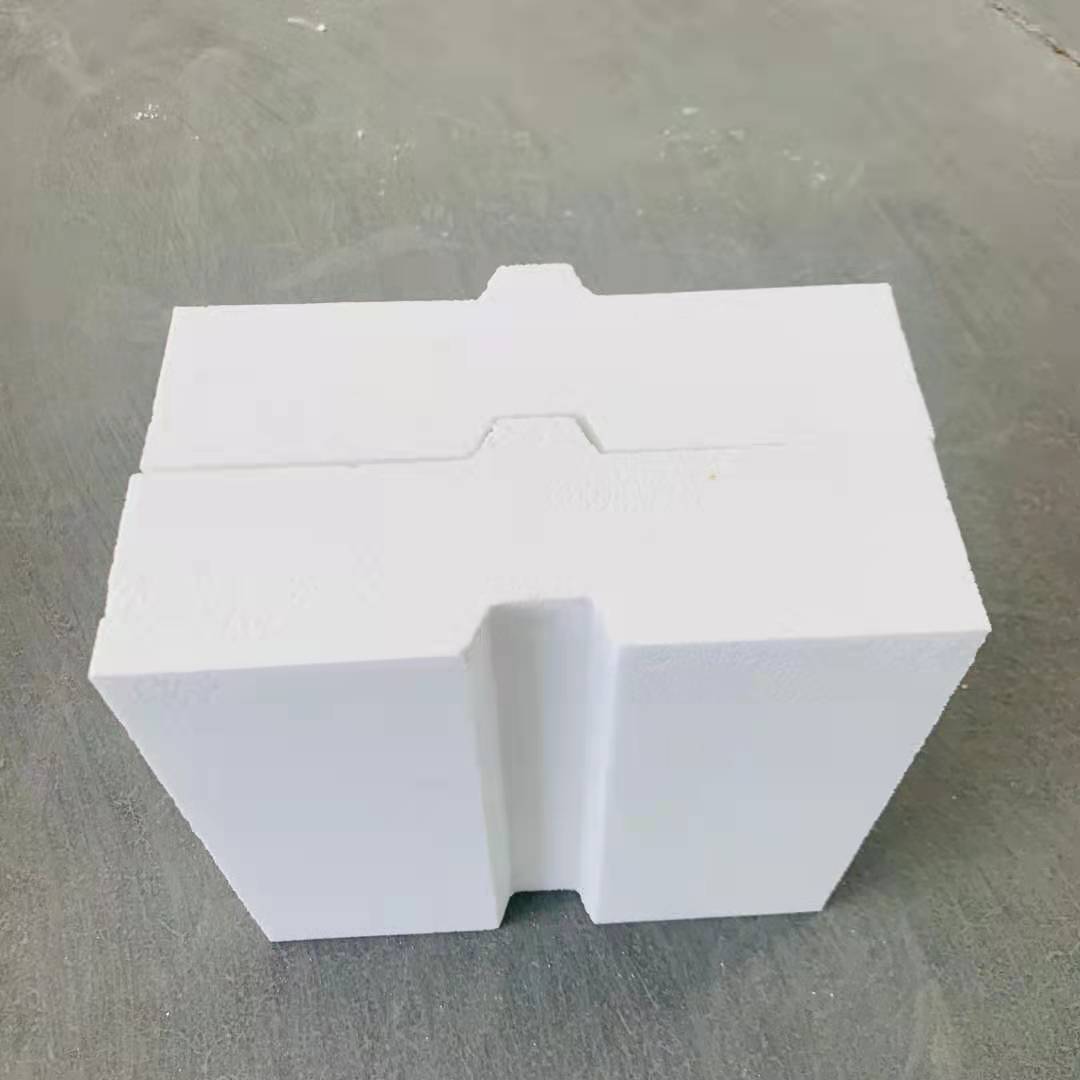

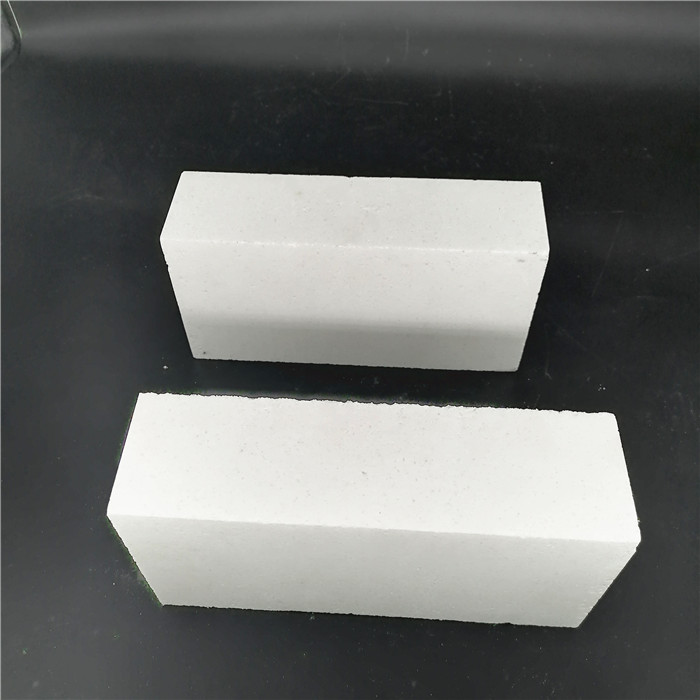

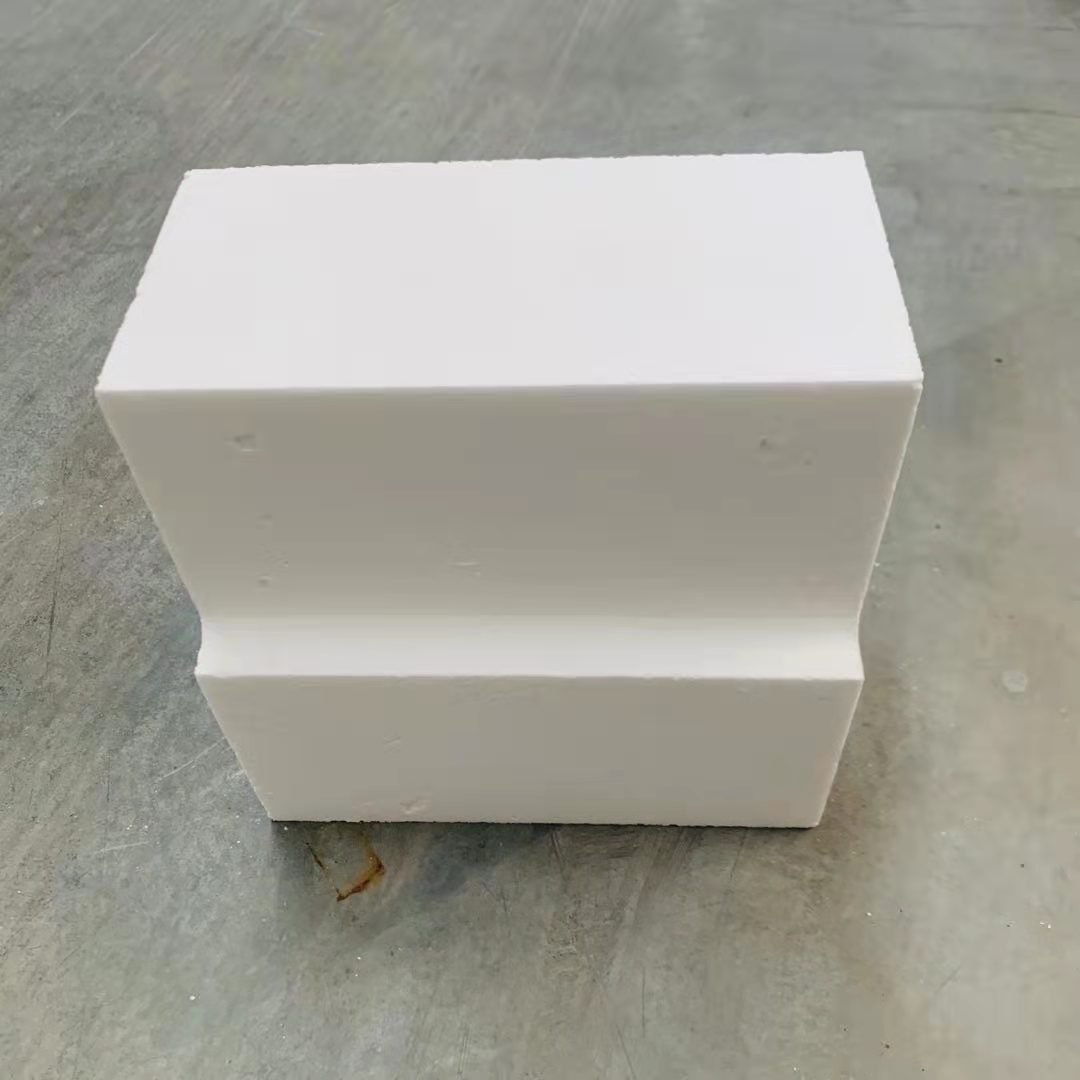

Competitive price corundum brick for refining furnace in steelmaking industry

Corundum bricks for refining furnace in steelmaking industry refer to refractory products with alumina content higher than 90% and corundum as the main crystal phase. Very high normal temperature compressive strength (up to 340MPa).

Competitive price corundum brick for refining furnace in steelmaking industry

| Items | HT99 | HT98 | HT96 | HT90 |

| Al2O3,% ≥ | 99 | 98 | 96 | 90 |

| Fe2O3,% ≤ | 0.15 | 0.3 | 0.4 | 0.5 |

| SiO2,% ≤ | 0.3 | 0.35 | 0.38 | 0.4 |

| Bulk Density,g/cm3 ≥ | 3.2 | 3.2 | 3.1 | 3 |

| Apparent Porosity,% ≤ | 18 | 20 | 20 | 20 |

| Cold Breaking Strenght,Mpa | 90 | 90 | 80 | 80 |

| Refractoriness Under Load,ºC(0.2Mpa,0.6%) | 1740 | 1740 | 1720 | 1700 |

| Heating Linear Change,% | ±0.2 | ±0.2 | ±0.2 | ±0.3 |

| 1600ºC*2h | 1600ºC*2h | 1550ºC*2h | 1550ºC*2h |

Competitive price corundum brick for refining furnace in steelmaking industry

Blast furnace,hot blast furnace(stove); glass kiln,ceramic kiln,lime kins,kiln car,tunnel kiln,rotary kiln; electric furnace; Steel-making secondary refining furnace, Petrochemical industry furnace, metallurgy industry Furnaces, heat treatment furnace, Furnaces of chemical industry and construction industry, Furnace of incineration of garbage, recirculating fluidized bed furnace.

Competitive price corundum brick for refining furnace in steelmaking industry

Packaging for Corundum brick

1.Pallet+Paper or Steel angle bead+Paper board +Plastic or Steel

belt +Plastic film

(1)Wooden pallet size:Usually0.92*0.92m(standard brick),but 1*1m

(special shape brick) at most,

(2)Load weight of each pallet:Usually 1.5-1.7Tons, max 2.0 Tons.

(3)20 Foot Container can be loaded max 25-26Tons, about

13-16Pallets.

2.Can make the package according to customer's requirements.

Competitive price corundum brick for refining furnace in steelmaking industry

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers,

which can be summarized in four aspects: reliable quality, timely

delivery, reasonable price and considerate service.The company will

continue to adhere to the corporate spirit of "contributing to

society and serving customers" and the business philosophy of

"mutual benefit, win-win, integrity, efficiency, preciseness and

responsibility".Our company is willing to develop a wide range of

technical exchanges with colleges and universities and colleagues

from all walks of life at home and abroad in a flexible and

diversified way.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium

corundum brick, fireproof ball lightweight insulation brick, wear-resistant pouring

material, corundum pouring material, low cement high strength

pouring material, impermeable material, self-flowing material,

plastic material, and various types of refractory materials.For

different industries, the cement industry with anti-flaking

high-alumina bricks, alkali resistant bricks, phosphate

bricks;Boiler industry USES all kinds of brand wear-resisting

brick, corundum brick, mullite brick and other finalizing

materials.The company insists on "product quality is the life,

enterprise integrity is the foundation", in the fierce market

competition, won many users' trust and praise.The products are sold

all over the country, as far as Vietnam, India, South Korea,

Pakistan, kazakhstan, Malaysia and other southeast Asian countries

and regions.

Competitive price corundum brick for refining furnace in steelmaking industry

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000 tons.

3. Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

South Korea, Vietnam, Pakistan, Bulgaria, French, India, Congo,

Angola, South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester Bulk Density Tester The Pressure Tester

Refractoriness Tester

Competitive price corundum brick for refining furnace in steelmaking industry

Q1:Are you a manufacturer or trader?

A:Factory+trade(mainly factories,meanwhile,we operates other related products)

Q2:What's the MOQ of trial order?

A:No limit, We can offer the best suggestions and solutions according to your needs.

Q3:After an order is confirmed,when deliver?

A:15-25days after deposit; if customer sized, 35days.

Q4:Which payment terms can you accept?

A:T/T,L/C,Western Union,Moneygram,Paypal are available

Q5:How about your company's certification?

A:ISO9001 and Test Report,also we could apply other necessary

certification.

Q6:Can you offers samples?

A:Of course, samples are free but freight paid by the buyers.

Q7: What is the service life of your bricks?

A:Depend on brick types, using conditions and methods.

Q8: Can we visit your factory?

A:Of course,welcome to visit at any time. Seeing is believing.

Q9:How to solve the quality problems?

A:If the products have quality problems, we will be responsible to offer compensation.

If you need sintered corundum brick for refining furnace in steelmaking industry, feel free to contact me.

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)firebricks-supplies.com