Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

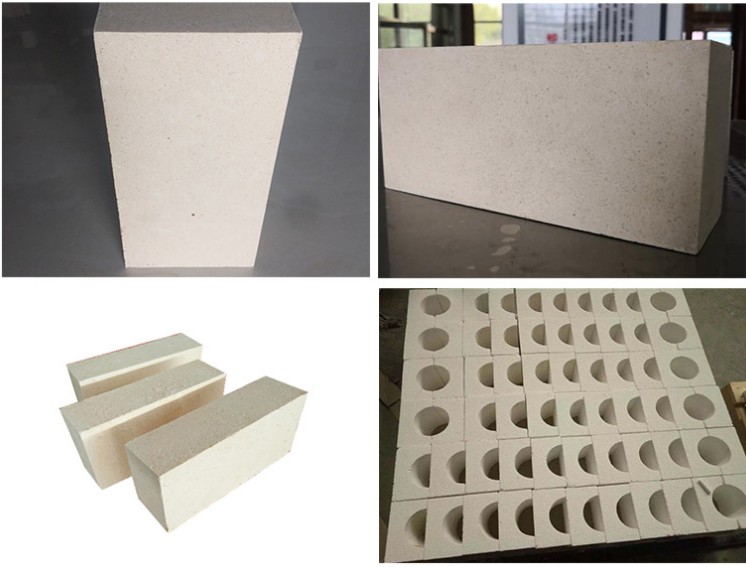

High density Zirconia

mullite refractory brick For Glass Furnace melting pool

Technical datas of Zirconia mullite refractory brick

| Chemical Composition | Al2O3% | ≥60 | |

| ZrO2% | ≥20 | ||

| Fe2O3% | ≤0.5 | ||

| Apparent Prosity (%) | 15 | ||

| Bulk Density (g/cm3) | 3.2 | ||

| Cold Crushing Strength | 150Mpa | ||

| Refractoriness under Load(℃) | 1650 | ||

Manufacturing process of Zirconia mullite refractory brick

Characteristics of Zirconia mullite refractory brick:

1. Resistance to glass liquid and alkali corrosion, erosion

resistance

2. High mechanical strength, good thermal shock stability

3. Reheating shrinkage and high temperature creep are small

4. Dense crystal structure

Zirconium mullite brick application: mainly used for paving the

bottom of the glass melting part, paving the bottom of the cooling

part, small furnace, regenerator lattice body, L-shaped hanging

wall nose area, etc.

It is an indispensable key supporting material for a wide range of

applications in large float glass kilns.

It is used in large glass kiln melting pool, picture tube kiln,

regenerator partition wall brick, and chemical and metallurgical

industry kilns that are corroded by solution.

Packing of Zirconia mullite refractory brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of Zirconia mullite refractory brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000 tons.

3. Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

Vietnam, Pakistan, Bulgaria, French, India, Congo, Angola, South

Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

Certificates

Mobile Phone:+8618037198058

WeChat / Whatsapp / Skype: +8618037198058

E-mail: sales03(at)firebricks-supplies.com