Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

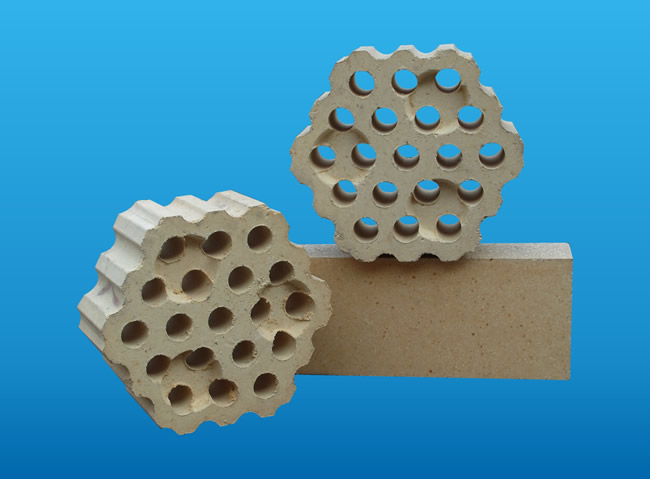

Glass melting furnace / hot blast stove use checker refractory bricks with holes to insulation

Glass melting furnace / hot blast stove use checker refractory bricks with holes to insulation are classified according to the alumina content which is from lowest 48% to highest 95%, manufactured from mineral of bauxite, corundum, etc. by mixing, press-forming, drying, sintering and machining. low porosity fireclay checker bricks feature stable mechanical strength and thermal shock resistance, with high refractoriness of no lower than 1880℃.

Description:

Glass melting furnace / hot blast stove use checker refractory

bricks with holes to insulation

Feature:

1. bricks are made from high quality bauxite

2. dry pressed

3. burned under tunnel kiln

4. accurate dimension

5. high strength

Applications:

1. Steel furnaces

2. Iron making furnaces

3. Glass kiln

4. Ceramic tunnel kiln

5. Cement kiln

Item | Properties | |||||

| SK40 | SK38 | SK37 | SK36 | SK34 | |

Al2O3 ,% | ≥80 | ≥75 | ≥65 | ≥55 | ≥48 | |

Refractoriness °C | ≥1790 | ≥1790 | ≥1790 | ≥1770 | ≥1750 | |

Bulk density,g/cm3 | 2.65 | 2.5 | 2.45 | 2.4 | 2.3 | |

Softening temperature under load | 1530 | ≥1520 | ≥1500 | ≥1470 | ≥1420 | |

Permanent linear change,% | 1500°CX2H | +0.1 | +0.1 | +0.1 | +0.1 |

|

| 1450°CX2H |

|

|

|

| +0.1 |

Apparent porosity,% | 22 | ≤23 | ≤23 | ≤22 | ≤22 | |

Cold Crushing strength Mpa | 55 | ≥50 | ≥45 | ≥40 | ≥35 | |

Application | All industrial furnace | |||||

Our company produces different types of refractory checker brick available for different Applicaitons.

Glass melting furnace / hot blast stove use checker refractory bricks with holes to insulation

Packaging of checker refractory bricks with holes:

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet:1.5-2.0 tons.

Shipping of checker refractory bricks with holes:

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

Glass melting furnace / hot blast stove use checker refractory bricks with holes to insulation

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials: according to

the chemical content,raw materials are classified into different

levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management: inspection of product

standardization of quality of each product by process control and

experimentation, taking corrective measures timely whenever

deviations are noted.

4.Before delivery, the inspectors will inspect the size,appearance,

physical and chemical properties of brick again in factory.

Glass melting furnace / hot blast stove use checker refractory bricks with holes to insulation

1. Strong professional:

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory' s production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

2. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece, Spain, Congo, Angola, South Africa, and Maldives, Jordan and so on. The export figure is more than USD 4 million.

3. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

4. Testing equipment;

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester