Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Lower price high quality ladle tundish nozzle for Continuous Casting Process

Tundish nozzles for continuous steel casting are made of zirconia and baddeleyite, formed by high tension and baked in high temperature when stablized by special technology. Different sizes and types of zirconia nozzles are designed and made according to users' different steel-making conditions and requirements.

The tundish nozzle is one of the key refractory materials for continuous casting of billet. The tundish nozzle plays the role of controlling the flow rate of crystallization of molten steel and stabilizing the casting speed. The uniform and stable flow of molten steel through the tundish nozzle into the crystallizer is necessary to ensure the continuous casting. condition. Whether it is a zircon nozzle or a zirconium nozzle, it is often used in the process of expanding the diameter of the nozzle, bursting, falling off, and even some nozzles may be blocked, which may affect normal production.

Lower price high quality ladle tundish nozzle for Continuous Casting Process

Features of Tundish Nozzles for Continuous Casting Process:

1.Low expansion, supprior resistance to erosion/corrosion and

thermal shock cycling.

2.Long and extended casting sequence times

3.Controlled and stable casting speed

4.Resistance to oxygen lancing

Our high purity and density ZrO2 tundish nozzle have the excellent

shock stability, strong errosion resistance, durable working time

etc features. Our tundish nozzles are different from the

one of Inida, UK, Germany, etc. origin. We have the high density of

5.4g/cm3, taking the special material and technology, automatic

production equipment, enough firing time, then excellent property

than them. For the tundish nozzle inserts, we have making testing

on 150tons ladle for 95% zirconia products, our tundish nozzle can

keep working 10-12 hours, even longer.

Our High performance 95% tundish nozzle has the high purity

and density, excellent erosion, thermal shock stability, crushing

resistance, etc. Tundish nozzles are mainly control the steel

liquid flowing amount into the mould.

Physical & Chemical Index of Tundish Nozzle:

| Zirconia Insert | |||||

| ZrO2+HfO2 % | ≥ | 93 | 94 | 95 | |

| Bulk Density (g/cm3) | ≥ | 5 | 5.2 | 5.4 | |

| Apparent Porosity % | ≤ | 8 | 7 | 6 | |

| Cold Crushing Strength (Mpa) | ≥ | 90 | 100 | 100 | |

| Refractoriness under Load 0.2Mpa (℃) | ≥ | 1790 | 1790 | 1790 | |

| Zirconia metering nozzle (Alumina sleeve) | |||||

| Brand | GD-1 | GD-2 | GD-3 | GD-4 | |

| Al2O3% | ≥ | 65 | 70 | 70 | 75 |

| C % | ≥ | 5 | 5 | ||

| Bulk Density (g/cm3) | ≥ | 2.6 | 2.6 | 2.7 | 2.7 |

| Apparent Porosity % | ≤ | 23 | 23 | 22 | 22 |

| Cold Crushing Strength (Mpa) | ≥ | 40 | 40 | 45 | 45 |

Lower price high quality ladle tundish nozzle for Continuous

Casting Process

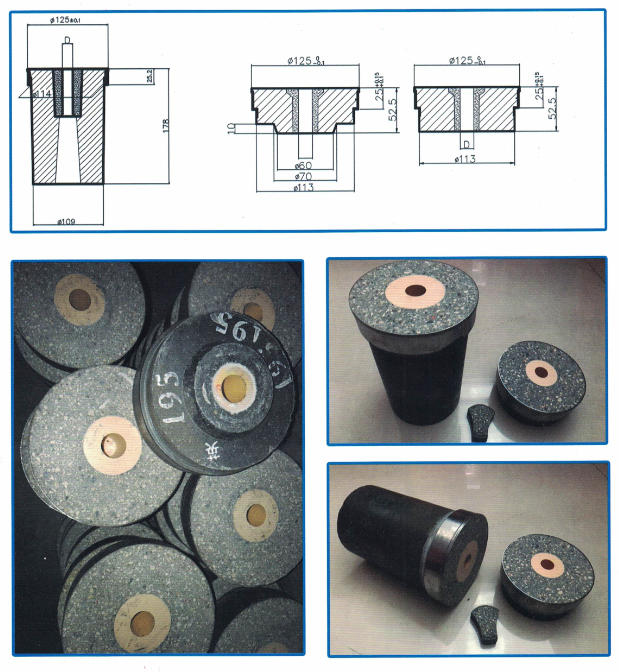

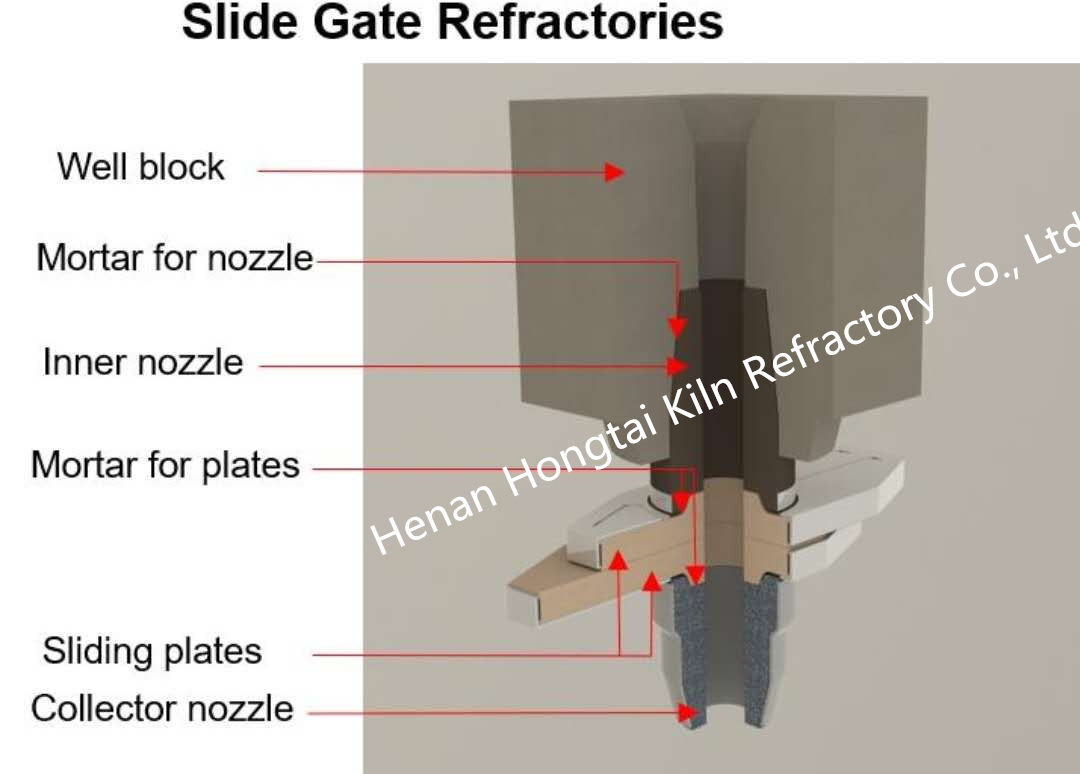

The structural principle of Tundish Nozzle:

The tundish nozzle is a combination of inner core and exterior. The

inner core is made of stabilized zirconia and zircon sand,

producing through molding machines and high-temperature

calcination. The exterior is made of zirconium and corundum,

producing through molding machines and low-temperature baking.

Tundish nozzle is located at the bottom of the tundish, it's the

channel of liquid steel to flow from the tundish into the

crystallizer.

Tundish nozzle usage:

In casting steel tundish nozzle zirconia inserts are mainly

used in successive-casting intermediary small square adobes, big

square adobes, rectangle adobes and small board adobes.

Lower price high quality ladle tundish nozzle for Continuous

Casting Process

Packaging for tundish nozzle:

1.International standard seaworthy exportable packing.

2.Wooden pallet.

3.Wooden / bamboo case (box)..

4.Further packing information will be based on customer's

requirements.

Shipping details for tundish nozzle:

1.The tundish nozzle sample willl be send by International

expresses FEDEX/DHL/UPS/TNT.

2.The goods are transport by shipping.

Payment terms for tundish nozzle:

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance

before delivery or negotiations to solve.

2. MOQ: Usually 100 pcs

Delivery time for tundish nozzle:

1.Tundish nozzle Stocks:Within 5-7 days after receive the deposit.

2.Customization:Within 15-30 days after receive the deposite.

Lower price high quality ladle tundish nozzle for Continuous Casting Process

Henan Hongtai Kiln refractory is an independent manufacturer of refractories, heat resistant products and high temperature insulation materials which follows the tradition of refractory and heat resistant manufacturing in Xinmi, Henan, since 2002.

Our products include fire cement, fire bricks, refractory setting cements/mortars, plastic mouldables refractories, high alumina refractory products, zirconia refractory products, magnesia refractory products, silica refractory products, carbon refractory products, silicon carbide refractory products, acid resistant cements and refractory castables for use in industries including steel plants, heat and power stations, foundries both ferrous and non-ferrous, cement producers, lime producers, glass works, ceramics, coke plants, incinerators, renewable energy, chemical works, sugar refineries and petrochemical industry.

We co-operate with a variety of companies worldwide. Within the scope of the global strategy, each market is approached individually to ensure that every customer’s needs are met. Our key success criteria are: high quality products combined with competitive prices to the satisfaction of our clients.

Lower price high quality ladle tundish nozzle for Continuous Casting Process

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000 tons.

3. Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

Korea, Vietnam, Pakistan, Bulgaria, French, India, Congo, Angola,

South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester Bulk Density

Tester The Pressure Tester

Refractoriness Tester

Hongtai Kiln Refractory has professional sales and after-sale service team who provide customers all-around service about product selection, transportation, installation and operation technology training etc. Now we have established cooperation relationship with many science and research units and our products have been sold to Vietnam, Thailand, Malaysia, South Korea, Pakistan, Kazakhstan, India, Japan, Indonesia, Germany, Italy, Mongolia, Russia, Argentina, colombia, Egypt, South Africa and etc.

We has over 20 years experience on producing Lower price high quality ladle tundish nozzle for Continuous

Casting Process.

Payment Guarantee: If couldn't trust us at first order, could use trade Assurance.

Jerry Li

Cell&WhatsApp: 0086-13373957739

Email: jerry(at)firebricks-supplies.com