Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Hot selling kiln refractory sic silicon carbide blocks

The refractory material made of SiC as the main raw material.

Containing SiC 72% ~ 99%. It is divided into clay, Si3N4, Sialon,

β-SiC, Si2ON2, and recrystallized.

Silicon Carbide brick high thermal conductivity, good wear

resistance, thermal shock resistance, corrosion resistance.

Can be used for aluminum electrolytic cell lining, molten aluminum

and ceramic kiln furniture, large and medium-sized blast furnace

body bottom, furnace waist and furnace belly, aluminum refining

furnace lining, zinc distillation tank lining.

Silicon carbide brick is the beginning of the 1970s, first in the

ultra-high-power electric furnace, then in the converter, furnace

refining furnace used, get a very good effect. Thus, it is

recognized that the graphite, carbon materials and high temperature

refractory oxide between the role of the combination.

Fracture toughness is poor, high temperature peeling, poor

resistance to slag, which is high temperature firing refractory

products fatal shortcomings, carbon refractory products break

through these weaknesses.

In the silicon carbide brick, magnesium oxide and graphite are

wrapped with each other, and there is no so-called sintering in the

traditional concept. The graphite has the advantages of high

thermal conductivity, low elastic modulus, small thermal expansion

coefficient, Due to the introduction of stone black, so that the

lining of refractory products, fracture toughness and resistance to

slag permeability of the essential improvement.

The main feature of silicon carbide bricks is the formation of

carbon conjugates on microstructures, which are formed by coking

carbonization at high temperatures by organic binders.

Silicon carbide brick is a non-burning products, the physical and

chemical indicators: MgO70 ~ 85%, C l0 ~ 20%, significant porosity

≤ 3%, bulk density 2.87g / cm3, compressive strength 40 ~ 50MPa,

1400 ℃ Folding strength l0 ~ 15MPa.

A refractory made of SiC as the main raw material. Contains SiC 72% to 99%. It is divided into silicon carbide bricks such as clay bonding, Si3N4 bonding, Sialon bonding, β-SiC bonding, Si2ON2 bonding and recrystallization. The silicon carbide brick has high thermal conductivity and good wear resistance, thermal shock resistance and corrosion resistance.

Hot selling kiln refractory sic silicon carbide blocks process

The formulation of coarse, medium and fine SiC should be 5:1:4.

The raw material for the manufacture of SiC bricks is generally

black SiC, and its chemical composition is as follows: SiC 98.0%,

free C O. 5%, Fe 0.2%, free SiO2 0.6%.

Due to the different bonding methods, the process is different.

(1) silicon nitride bonded silicon carbide brick: a blank formed by

using coarse, medium and fine silicon carbide particles and fine

silicon powder, and in pure N2 gas, a kind is produced at 1370 ° C.

26alpha;-SiC is the backbone and is in %26alpha; and

%26beta;-Si3N4. The silicon nitride of the matrix is bonded to the

silicon carbide brick. There is still a small amount of residual

silicon and SiO2N2 in the matrix, and the relative amounts of these

components vary from manufacturing plant to manufacturing plant.

(2) Combining silicon carbide bricks: SiC, silicon powder and

carbon powder are mixed and formed according to a certain ratio,

and fired in a reducing atmosphere at 1400 °C. In most cases,

carbon burning is used. During the firing process, a %26beta;-Si3N4

bonded SiC brick with %26alpha;-SiC as the framework and fine grain

%26beta;-SiC as the matrix was produced. %26beta;-SiC is formed by

the reaction of fine silicon powder with fine carbon powder during

the firing process. This product also contains a small amount of

residual silicon and carbon.

(3) Silicon oxynitride combined with silicon carbide brick: When

this brick is compounded, the proportion of fine silicon powder is

less than si. N. Combine the ratio of silicon carbide bricks. After

molding, it is fired in a N2-rich atmosphere (requiring a certain

partial pressure of O2), and the firing temperature is 1350 to 1400

°C. The finished product is a framework of %26alpha;-SiC, which is

a matrix of Si2ON2 combined with SiC bricks, and a small amount of

Si and Si3N4 are present in the matrix.

(4) Sialon combined with silicon carbide brick: Si3N4 and Al2O3

fine powder are blended in SiC with a certain particle size ratio.

After mixing, adding a binder, kneading, molding, and firing in a

reducing atmosphere

Hot selling kiln refractory sic silicon carbide blocks

Hot selling kiln refractory sic silicon carbide blocks

Packing:

Standard export wooden pallet with cardboard and PET strap.

1. Strong packing will protect the goods from any possible damage

during transit.

2. Solid packing and overall stuffing can prevent the cases from

vibration and jarring.

3. We must take necessary precaution that the packing can protect

goods from pilferage or rain.

4. We can confirm that we take every possible precaution to ensure

that our products reach our customers all over the world in prime

conditon.

Shipping:

By vessel or by train from any Chinese port, Samples can be delivered by International express.

Delivery:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods, etc.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

Henan hongtai kiln refractory co., LTD. Is well aware that there are thousands of demands from customers, which can be summarized in four aspects: reliable quality, timely delivery, reasonable price and considerate service.The company will continue to adhere to the corporate spirit of "contributing to society and serving customers" and the business philosophy of "mutual benefit, win-win, integrity, efficiency, preciseness and responsibility".Our company is willing to develop a wide range of technical exchanges with colleges and universities and colleagues from all walks of life at home and abroad in a flexible and diversified way.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our

aim."Scientific management, strong technical force, perfect testing

means, advanced technological equipment and stable product quality

are the guarantee of quality service.Henan hongtai kiln

refractories co., LTD sincerely hopes to cooperate with you hand in

hand and in good faith.

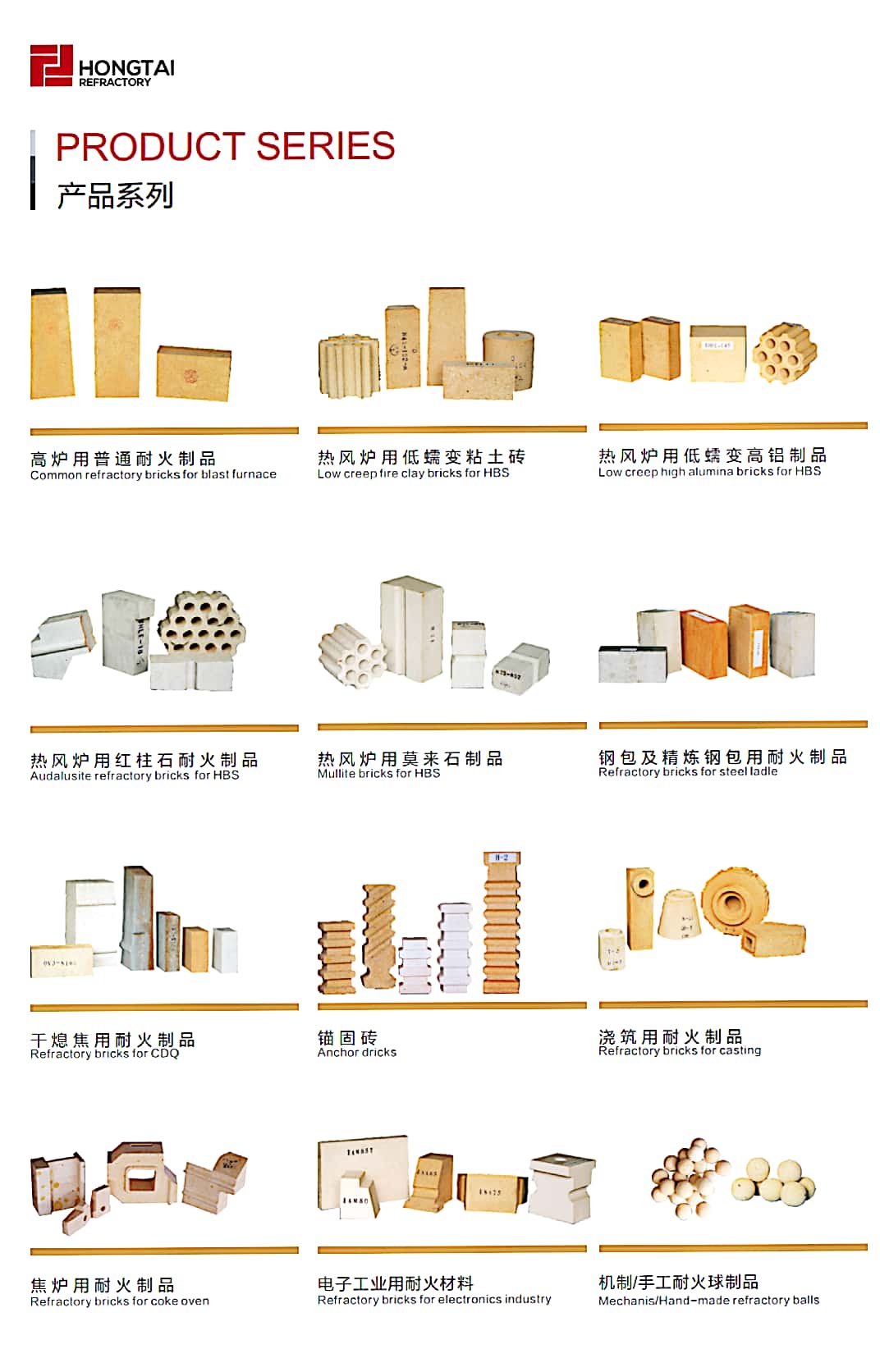

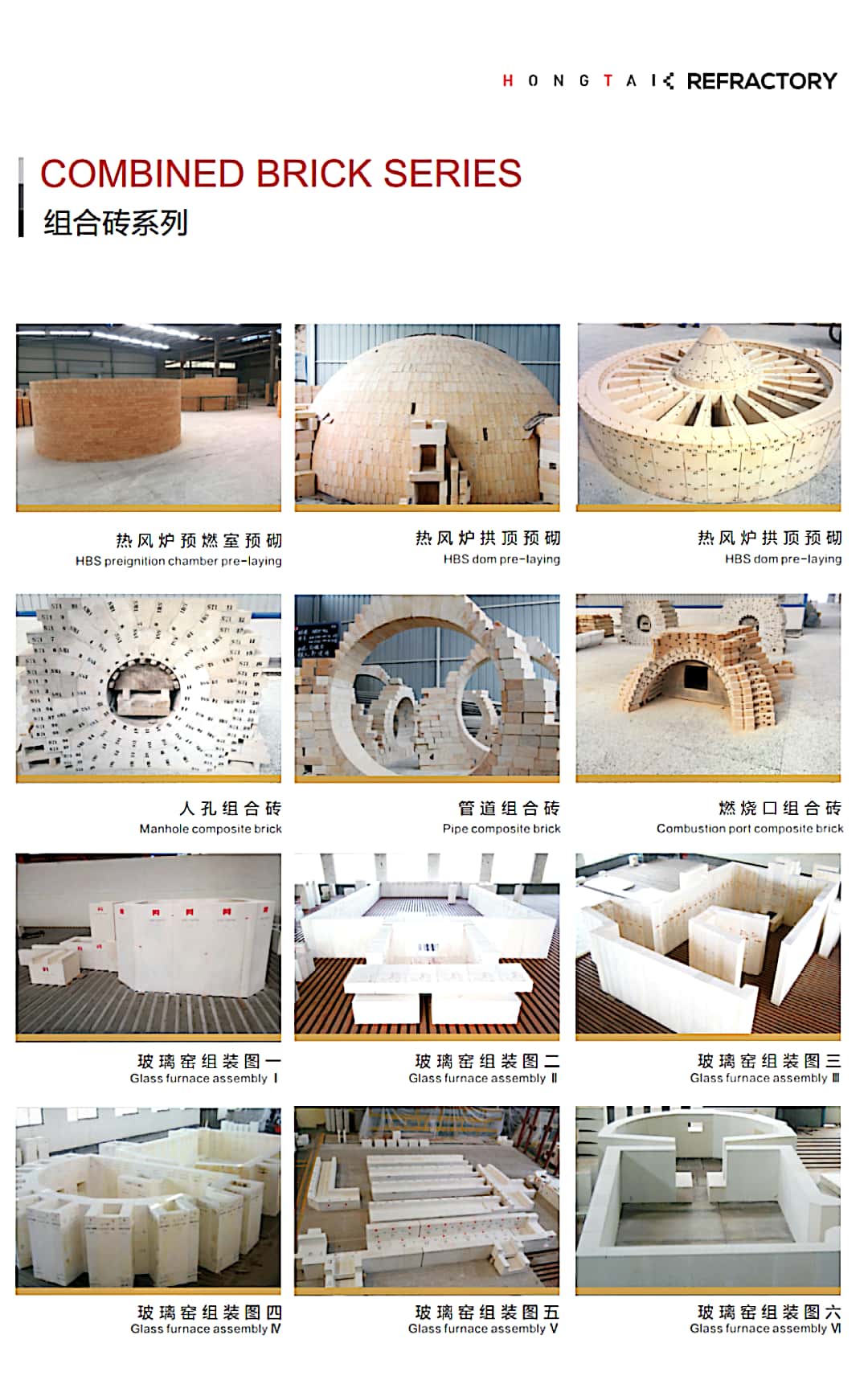

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium

corundum brick, fireproof ball lightweight insulation brick,

wear-resistant pouring material, corundum pouring material, low

cement high strength pouring material, impermeable material,

self-flowing material, plastic material, and various types of

refractory materials.For different industries, the cement industry

with anti-flaking high-alumina bricks, alkali resistant bricks,

phosphate bricks;Boiler industry USES all kinds of brand

wear-resisting brick, corundum brick, mullite brick and other

finalizing materials.The company insists on "product quality is the

life, enterprise integrity is the foundation", in the fierce market

competition, won many users' trust and praise.The products are sold

all over the country, as far as Vietnam, India, Korea, Pakistan,

kazakhstan, and other southeast Asian countries and regions.

1. Strong professional:

1. Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractorys

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000

tons.

3. Export experiences:

Now we have gained a global sales network reaching Taiwan, Russia,

Korea, Vietnam, Pakistan, Bulgaria, French, India, Congo, Angola,

South Africa, and so on.

4. Production equipment:

Production and testing equipments are new, complete and automated

or semi- automated. Such modern facilities and equipments have

provided the fine technical guarantee for the production and

testing.

5. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester