Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

carburetant/Carbon Anode Scrap/Carbon Additive for Copper Steel Smelting

Hongtai uses special production process to make the sulfur content below 500ppm, nitrogen content is 300ppm or less. It has improved the permeability of carbon particles and the rapid melt and absorption rate in the molten steel, to achieve high effect and high performance of carbon adding.

Application of Graphite calcined coke carbon additives

Used for casting, cast iron, cast steel and other additives, such as additives used in brake pads, used as friction material.

Specifications of carburetant/Carbon Anode Scrap/Carbon Additive for Copper Steel Smelting:

Hongtai selected high-carbon, low-sulfur raw materials, application of independent researched and developed flux technology, imports core control unit from Germany, greatly increase super dense connection and absorption rate of Graphite calcined coke carbon additives, so as to achieve better carbon effect.

Hongtai has calcined, graphite, roasting, low nitrogen, etc. in 10 categories, 122 kinds of Graphite calcined coke carbon additives in total, try best to meet the individual needs of carbon adding requirement of each customer.

Chemical and Physical index of carburetant/Carbon Anode Scrap/Carbon Additive for Copper Steel Smelting:

Items

| carbon additives | ||||

Graphite petroleum coke (Low Nitrogen) | Graphite calcined coke (Low Nitrogen) | Calcined coke | Calcined coal | Graphite powder | |

C (%) | >98.5 | >99 | >99 | >92 | >95 |

S(%) | <0.05 | <0.03 | <0.5 | <0.5 | <0.2 |

Ash(%) | <1 | <0.5 | <0.5 | <1.5 | <5 |

N(PPM) | <200 | <120 | <10000 | <3000 | <1000 |

Moisture(%) | <0.5 | <0.5 | <0.5 | <0.5 | <1 |

Volatile matter(%) | <0.5 | <0.5 | <0.5 | <0.5 | <2 |

Grit size | 0-1mm,1-3mm,1-5mm,3-8mm,1-10mm, or according to customer's requirement | ||||

carburetant/Carbon Anode Scrap/Carbon Additive for Copper Steel Smelting

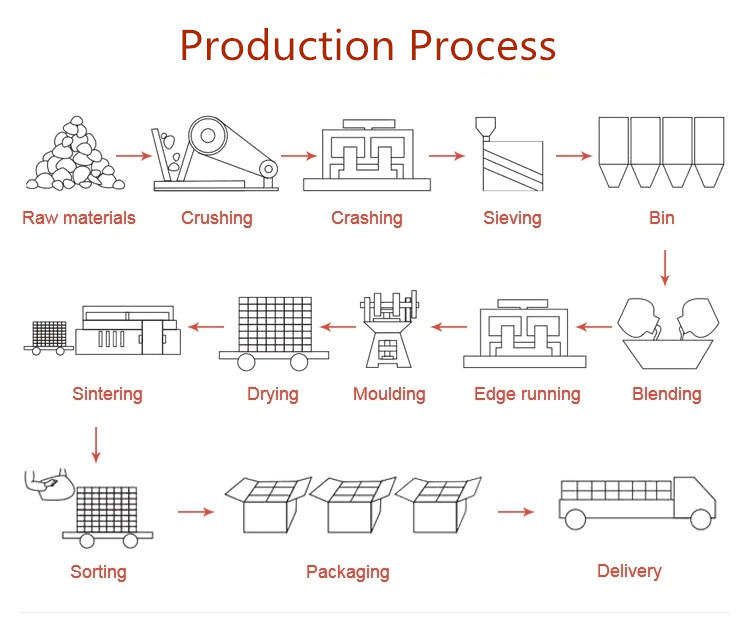

Process A of carburant agent

1. Check ash, volatile and sulfur content of raw coke.

2. Prepare raw materials in proportion.

3. Cast the coke into the calciner for calcination.

4. Calculate in calciner at 1200-1300 degrees for 40-48 hours

5. Discharge

6. cool material

7.Scroll to screening

8. Packaging

9. Delivery

Process B of carburant agent

1. Check ash, volatile and sulfur content of raw coke.

2. Prepare raw materials in proportion.

3. Cast the coke into the calciner for calcination.

4. Calculate in calciner at 1200-1300 degrees for 40-48 hours

5. Discharge

6. cool material

7. broken,vibrate and screen

8. Packaging

9. Delivery

carburetant/Carbon Anode Scrap/Carbon Additive for Copper Steel Smelting

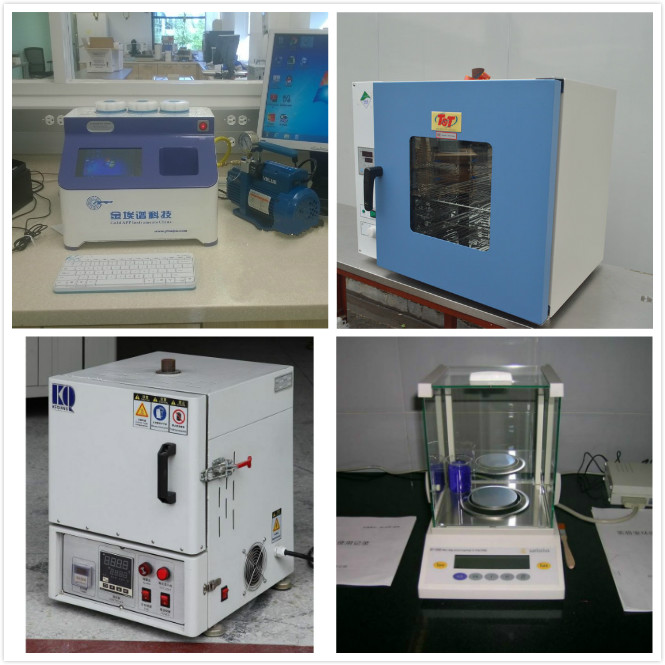

Precise testing and inspection is another important step in ensuring product quality. Hongtai products testing equipment use electronic balance imported from Germany. Each batch goods in the production process is supervised by the production department, business department, the audit department at the same time, to ensure that product quality and customer requirements keep consistent.

Our testing equipment include:Sulfur meter, Germany electronic balance,muffle furnace, real density tester, adjustable electric furnace, desktop oven, moisture analyzer, vibrating screen

carburetant/Carbon Anode Scrap/Carbon Additive for Copper Steel Smelting

Packaging of carbon additives

In the packaging process, as Hongtai promised to the customer, the packaging staff will weigh each bag cargo at least three times to ensure the accuracy and timeliness. The packages we use is in accordance with the customer's requirements.

The product can be packed in a variety of standards such as 5 kg, 20 kg, 30 kg, 50 kg and 1 tonne high density polyethylene package.Jumbo bags Packing: 0.75-1.15MT

shipping of carbon additives

1.Normal goods delivered by sea transport

2.Sample shipping by express

3.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

Payment Item:

1. Payment: T/T, Western Union,LC; Usually 30% deposits,70% balance

before delivery or negotiations to solve.

2. MOQ: Usually 1Tons

3. Quality Warranty: 1 years

carburetant/Carbon Anode Scrap/Carbon Additive for Copper Steel Smelting

Henan Hongtai Kiln Refractory Co., Ltd. is established in 2002, located in Xinmi City, 40kilometers southwest of Zhengzhou City in Henan Province, close to Jingguang, Longhai railway lines, with road transport facilities. Rich resources of Refractory materials, adequate and qualified fuel in this area, provide unique conditions for refractory production, shipping and refractory industry development.

Main products include different kinds of refractory brick:Fire Clay

Brick, High Alumina Brick, Light Weight Insulating Brick,Corundum

Brick,Mullite Brick,AZS Bricks, Refractory Balls ,Refractory

concrete,refractory castable,High alumina castable etc.They

are widely used in Iron and steel, Nonferrous metals, Building

materials(Cement,Glass,Ceramic), Petrochemical, Energy &

Incineration etc industries. Our products have been exported to

India,Turkey,Vietnam,Malaysia and Kazakhstan etc.

“Science-Technology Innovation, Cooperation for Win-Win”, Henan

Lite Refractory Material Co., Ltd will do the best for the clients

in a timely and effective way.

Our Advantage:

1. SGS certified Chinese supplier

2. Provide product search, offer, quality control, warehousing,

international logistics, etc one-stop service

3. Offer customization product and all-around product application

programs according to customers' requirement

4. Supply FREE sample and accept small orders

5. Alternative Packages

6. Operated by in professional teams, offer quality after-sales

service and technical support.

Service we can provide:

1. Quick and Positive reply after receiving your inquiry.

2. Free samples before shippment.

3. Quality control before and during shipment.

4. Loading photos as required.

5. Pompt shipment with right shipping line.

6. SGS and BV certification as required.

7. Packing according to Clients' requirement.

1.What's your payment terms?

Various payment will be supported

2.What's your delivery time?

Usually within 15-30 days after receive the deposit.

3.How about the packing?

25 kg/bag,outer woven bags with inner plastic lining.

4.What documents you provide?

Usually, we provide Commercial Invoice, Packing List, Bill of

lading, COA , TDS. etc.If your markets have any special

requirements, let us know.

5.How about the validity of the products?

According to the products you ordered.

6.What is loading port?

Usually isTianjin, Shanghai or Qingdao.