Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

Recarburizers are used for refining steel recarburizers and cast iron recarburizers, as well as other additives to recarburizers, such as brake pad additives, as friction materials. The recarburizer belongs to the external steelmaking and iron-making carbon-increasing raw materials. High quality carbonizers are essential additives for the production of high quality steel.

There are many kinds of raw materials for recarburizers, and the production process is also different. There are various types of wood, carbon, coal, coke, and graphite. There are many small types under various classifications. High-quality recarburizers generally refer to graphitized recarburizers. Under high temperature conditions, the arrangement of carbon atoms is in the microscopic form of graphite, so it is called graphitization. Graphitization can reduce the content of impurities in the recarburizer, increase the carbon content of the recarburizer, and reduce the sulfur content.

The recarburizing agent is used in casting, which can greatly increase the amount of scrap steel, reduce the amount of pig iron or use no pig iron. In the feeding mode of electric furnace smelting, the recarburizing agent should be placed together with the charging materials such as scrap steel, and the addition of small doses can be added to the surface of the molten iron. However, it is necessary to avoid feeding large quantities into the molten iron to prevent excessive oxidation and the carbonization effect is not obvious and the carbon content of the casting is insufficient. The amount of the recarburizer added is determined according to the ratio of other raw materials and the carbon content. Different types of cast iron, choose different types of recarburizers according to your needs. The characteristics of the recarburizer itself select pure carbon-containing graphitized materials to reduce excessive impurities in the pig iron. The selection of the recarburizer can reduce the casting production cost.

For casting, cast iron, cast steel, castings will have a carbon requirement, then the carbonizer is to increase the carbon content in the molten iron. For example, in the smelting, the common charge is pig iron, scrap steel, and recycled material. The carbon content of pig iron is high, but the purchase price is higher than that of scrap steel. Therefore, increasing the amount of scrap steel, reducing the amount of pig iron, and adding carbonizer can play a role in reducing the cost of castings.

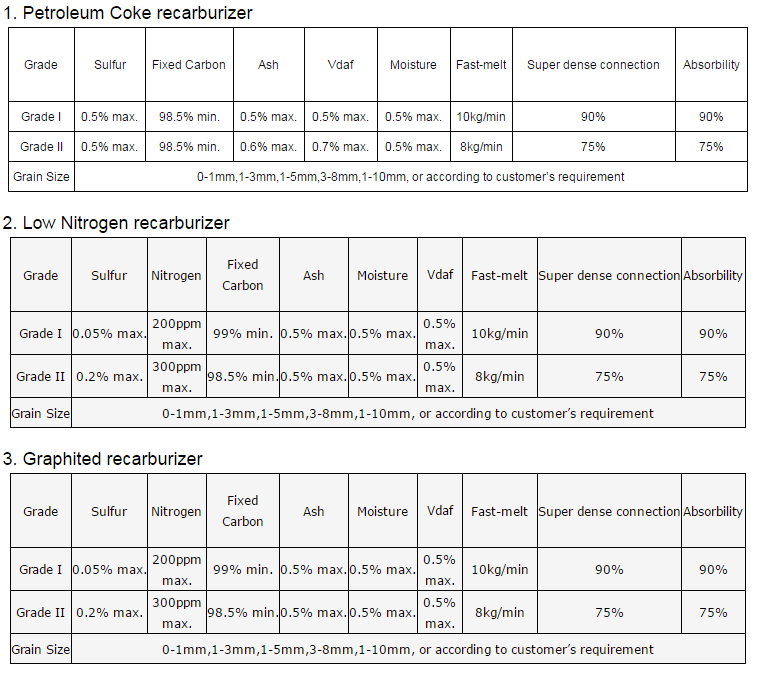

physical and chemical indicators

In the smelting process, due to improper ingredients or improper loading and excessive decarburization, the carbon content in the steel sometimes fails to meet the requirements of the top stage. At this time, carbon is added to the molten steel. Commonly used recarburizers include carbon-increasing pig iron, electrode powder, petroleum coke powder, charcoal powder and coke powder. In the case of converter smelting medium and high carbon steel, petroleum coke containing little impurities is used as a recarburizer. The requirement for the recarburizing agent for top-blown converter steelmaking is that the fixed carbon is high, the content of ash, volatile matter and sulfur, phosphorus, nitrogen and the like is low, and it is dry, clean and moderate in particle size.

Its fixed carbon composition is:

w(C)>96%, volatile matter ≤1.0%, w(S)≤0.5%, w(moisture)≤0.55%, particle size is 1-5mm.

The particle size is too fine to be easily burned, and when it is too thick, it floats on the surface of the molten steel and is not easily absorbed by the molten steel. For the induction furnace, the particle size is 0.2-6mm, wherein the steel and other ferrous metals have a particle size of 1.4-9.5mm, the high carbon steel requires low nitrogen, the particle size is 0.5-5mm, etc., and the specific need to smelt the workpiece according to the specific furnace type. The specific types and details of the specific judgment and selection.

1. Furnace input method:

The recarburizer is suitable for melting in an induction furnace, but it is not the same depending on the process requirements.

(1) The use of a recarburizer in the intermediate frequency electric furnace smelting can be added to the lower part of the electric furnace according to the ratio or carbon equivalent requirement, and the recovery rate can reach above 95%;

(2) If the amount of carbon is insufficient to adjust the carbon content, firstly clean the slag in the furnace, add the carbon-increasing agent, and increase the carbon solution by electromagnetic heating, electromagnetic stirring or manual stirring, and the recovery rate can be about 90%. The low-temperature carbonization process is adopted, that is, when only a part of the charge is melted, and the temperature of the molten iron is low, all the carbon-reducing agents are added to the molten iron at one time, and the solid charge is pressed into the molten iron to prevent the iron from being exposed. Liquid surface. This method can increase the carbon content by more than 1.0%.

2. Carbon increase outside the furnace:

(1) Spray graphite powder inside the bag

The graphite powder is used as a recarburizer, and the blowing amount is 40kg/t, which is expected to increase the carbon content of the molten iron from 2% to 3%. As the carbon content of the molten iron gradually increases, the utilization rate of carbon decreases, the temperature of the molten iron before the carbon addition is 1600 ° C, and the average after the carbon increase is 1299 ° C. Spray graphite powder to increase carbon, generally using nitrogen as carrier, but under industrial production conditions, it is more convenient to use compressed air, and oxygen in compressed air produces CO, chemical reaction heat can compensate part of temperature drop, and CO reducing atmosphere is beneficial to Improve carbonization.

(2) Use of recarburizer when tapping

The 100-300 mesh graphite powder recarburizer can be placed in the bag or flushed with the flow from the iron tapping tank. After the molten iron is discharged, the carbon is dissolved and absorbed as much as possible, and the carbon recovery rate is about 50%.

Recarburizers can be used as a material for cast iron recarburizers, and artificial graphite, calcined petroleum coke, natural graphite, coke, anthracite, and mixtures made of such materials are commonly used.

Artificial graphite

Among the above various recarburizing agents, the best quality is artificial graphite.

The main raw material for the manufacture of artificial graphite is powdered high-quality calcined petroleum coke, in which asphalt is added as a binder, and a small amount of other auxiliary materials are added. After the various raw materials are mixed, they are press-formed and then treated in a non-oxidizing atmosphere at 2500 to 3000 ° C to make them graphitized. After high temperature treatment, the ash, sulfur and gas contents are greatly reduced.

Due to the high price of artificial graphite products, the artificial graphite recarburizers commonly used in foundries are mostly recycled materials such as chips, waste electrodes and graphite blocks when manufacturing graphite electrodes, so as to reduce production costs.

When smelting ductile iron, in order to make the metallurgical quality of cast iron superior, the artificial carbon should be preferred.

2. Petroleum coke

Petroleum coke is a widely used recarburizer.

Petroleum coke is a by-product of refined crude oil. Residual oil and petroleum asphalt obtained by vacuum distillation or vacuum distillation can be used as raw materials for petroleum coke, and then coke is obtained to obtain raw petroleum coke. The production of raw petroleum coke is less than 5% of the amount of crude oil used. The annual production of petroleum coke in the United States is about 30 million tons. The raw petroleum coke has high impurity content and cannot be directly used as a recarburizer. It must be calcined first.

Raw petroleum coke has spongy, needle-like, granular and fluid states.

Sponge petroleum coke is produced by a delayed coking process. It is usually used as a fuel for calcination because it has a high sulfur and metal content, and can also be used as a raw material for calcining petroleum coke. The calcined sponge coke is mainly used in the aluminum industry and as a recarburizer.

The acicular petroleum coke is obtained by a delayed coking process using a raw material having a high content of aromatic hydrocarbons and a low impurity content. This coke has a needle-like structure that is easily broken, sometimes referred to as graphite coke, and is mainly used for the manufacture of graphite electrodes after calcination.

Granular petroleum coke is a hard granule. It is a raw material with a high content of sulfur and asphaltene. It is produced by delayed coking and is mainly used as a fuel.

The fluid petroleum coke is obtained by continuous coking in a fluidized bed. It is in the form of fine particles, has no directional structure, high sulfur content and low volatile content.

The calcination of petroleum coke is to remove sulfur, moisture, and volatiles. Calcination of raw petroleum coke at 1200~1350 °C can make it a substantially pure carbon.

The largest user of calcined petroleum coke is the aluminum industry, and 70% is used to make anodes that reduce bauxite. Calcined petroleum coke produced in the United States accounts for about 6% of cast iron recarburizers.

3. Natural graphite

Natural graphite can be divided into two types: flake graphite and microcrystalline graphite.

Microcrystalline graphite has a high ash content and is generally not used as a carbon reinforcer for cast iron.

There are many varieties of flake graphite: high carbon flake graphite needs to be extracted by chemical methods, or heated to high temperature to decompose and volatilize the oxides. This flake graphite has low yield and high price, and generally does not act as a recarburizer; low carbon flakes Graphite has a high ash content and should not be used as a recarburizer; it is mainly used as a carbon reinforcer for medium carbon graphite, but it is not used in large amounts.

4. Coke and anthracite

In the electric arc furnace steelmaking process, coke or anthracite may be added as a recarburizer during charging. Induction furnace smelting cast iron is rarely used as a recarburizer because of its high ash and volatile content.

Packaging of diatomaceous bricks

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of diatomaceous bricks

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

1. Quality assurance:All products are ISO qualified and monitored by complete QC system

2. Provide professional designing solution, field technical assitance and any other consulting.

3. Price advantage, provided by manufacturer directly,save much intermediate fees.

4. Professional and experienced service team, specialized in refractory production since 1986.

5. Large production capacity, short lead time of products.

6. 24*7 online service.

7. OEM service available.

1. How can I get your prompt quotation?

We can give you reply with quotation quickly if you kindly send the inquiry with the detail, such as the quantity, the specifications and the application of the products.

2. What is the MOQ (minimum order quantity)?

No limit

3. Which payment terms can you accept?

T/T,LC,Western Union,moneygram are available for us.

4. After an order is placed, when to deliver?

15-25days after confirming the order.

5. Does your company accept customization?

We accept OEM service.

6. How to solve the quality problems?

If the products don't conform to customer's samples or have quality problems, our company will be responsible to make compensation for it based on enough evidences.