Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

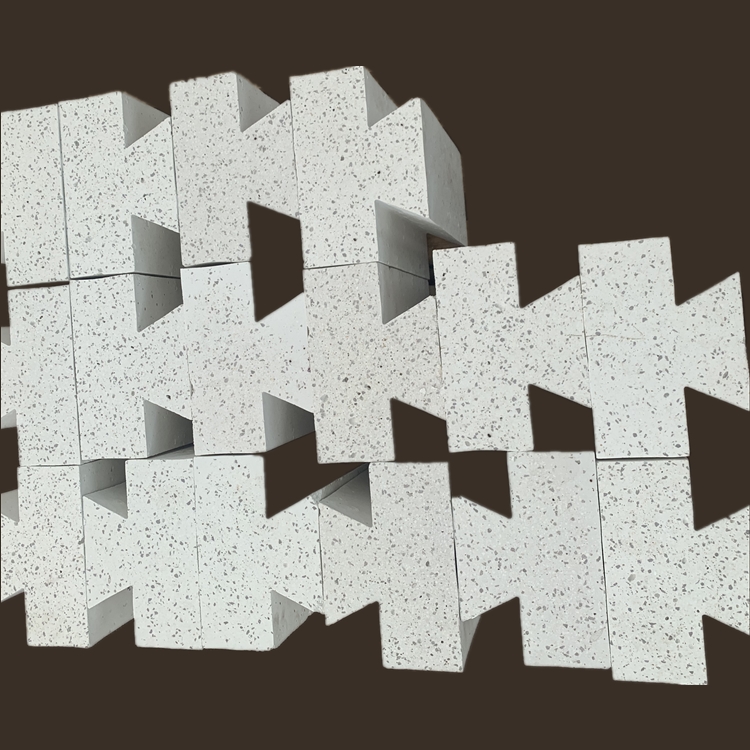

Thermal insulation material Low creep sillimanite bricks used in coke oven carbonization chamber

Introduction to Sillimanite refractory brick

Sillimanite refractory brick is a refractory bricks made of sillimanite minerals. The sillimanite is calcined at high temperature and converted to mullite and free silica. Sillimanite refractory brick is generally used high temperature firing method and mud casting method. Its physical and chemical properties are better than high alumina bricks, refractoriness 1770 ~ 1830 ℃, load softening start point 1500 ~ 1650 ℃.

Application of Sillimanite refractory brick

Sillimanite bricks are currently mainly used in the tin bath roof tiles of float glass production lines in the flat glass industry. Because sillimanite refractories have good high-temperature thermal stability, they are resistant to erosion and erosion by molten glass, and have little pollution to molten glass. It is suitable for equipment such as forehearths, feeders, and pipe-drawing machines in the glass industry, which can significantly improve productivity. Products include channel bricks, flow troughs, rotating pipes, bowls, bowls, mixing slurry, punches, barrels, fire-stop slag bricks, gate bricks, front arch bricks, rear arch bricks, bowl cover, and openings Various varieties and specifications such as bricks, burning nozzle bricks, beams, and cover bricks.

Classification of Sillimanite refractory brick

1. Classified by Al2O3 content in Sillimanite refractory brick

Class Ⅰ Al2O3 content>65%

Class Ⅱ Al2O3 content is 60%

Class Ⅲ Al2O3 content is 55%.

Technology of Sillimanite refractory brick

| Iterm | Indicators | |||

| Al2O3% | ≥ | 65 | 60 | 55 |

| Fe2O3% | ≤ | 1.0 | 1.0 | 1.5 |

| SiO2% | ≤ | 32 | 37 | 42 |

| Bulk Density (g/cm3) | ≥ | 2.5 | 2.35 | 2.3 |

| Apparent Porosity % | ≤ | 18 | 19 | 20 |

| Cold Crushing Strength (Mpa) | ≥ | 60 | 60 | 50 |

| Refractoriness under Load 0.2Mpa (℃) | ≥ | 1650 | 1600 | 1580 |

1.Production Process of Sillimanite refractory brick

1)Raw material to factory→checkout→burdening→stirring→mixing→taking

out the raw material,

2)Crushing→Mixing→Shaping→Drying→Firing→Inspection→Packaging and

Shipment.

2.Quality Assurance Process of Sillimanite refractory brick

1)Going out the furnace→checkout→packing→qualified product→putting

in storage→sale,

2)The process from raw to product are strictly tested by equipment.

1.Inspection and Control of incoming raw materials:

according to the chemical content,raw materials are classified into

different levels to ensure quality of brick first.

2.Inspection and control of the process: during the

production,every brick will be weighed twice strictly to reduce the

error of weight .

3.Quality audit by quality management:

inspection of product standardization of quality of each product by

process control and experimentation, taking corrective measures

timely whenever deviations are noted.

4.Before delivery, the inspectors will inspect the

size,appearance, physical and chemical properties of brick again in

factory.

Sillimanite refractory brick have followed characteristics :

1.high softening temperature under load

2.thermal shock resistance

3.chemical resistance, etc.

Packaging of Sillimanite refractory brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

3.230*114*65mm:512PCS/Pallet, 230*114*75mm:448PCS/Pallet.

Shipping of Sillimanite refractory brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quanlity and quantity

guaranteed, and also in accordance with the contract and customer's

requirment completely.

1. Strong professional:

Our company has thirty years producing experience in refractory product. Our manager will supervise on a various refractory' s production materials, process control, quality supervision and package delivery, and ensure the products are 100% qualified.

2. Annual exports:

Now we have gained a global sales network reaching Taiwan, Russia, Mongolia, South Korea, Vietnam, Pakistan, Bulgaria, Finland, Greece, Spain, Congo, Angola, South Africa, and Maldives, Jordan and so on. The export figure is more than USD 4 million.

3. Production equipment:

Production and testing equipments are new, complete and automated or semi- automated. Such modern facilities and equipments have provided the fine technical guarantee for the production and testing.

4. Testing equipment:

Our company's testing equipments as follows:

High Temperature RUL Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

Certificates