Henan Hongtai Kiln Refractory Co.,Ltd. |

|

Verified Suppliers

|

|

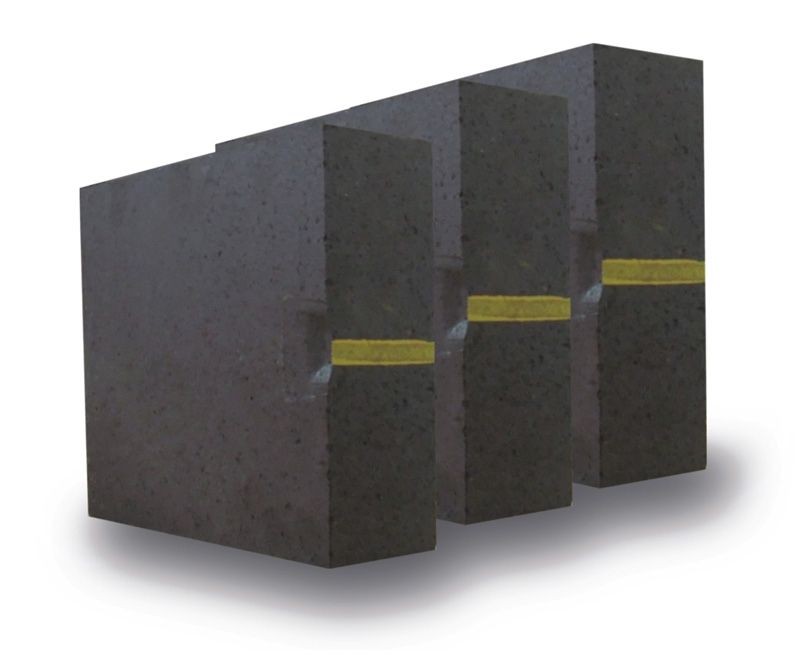

High Chrome Oxide Brick Refractory brick

High chromium brick is a kind of shaped refractory product with the content of chromium trioxide not less than 75% and the combined content of chromium trioxide, alumina and zirconia not less than 98%, which is made of industrial grade chromium trioxide and alumina as the main raw materials, or with a small amount of zirconia, etc.It has excellent corrosion resistance, high pressure strength at normal temperature, high temperature strength, excellent wear resistance, high refractoriness, excellent thermal shock resistance, high temperature volume stability and other characteristics.

Operating temperature had a great influence on the service life of

high chrome brick, the higher the temperature, cut loss rate, the

greater the service life of the brick is lower, in coal-water

slurry gasifier work environment, because of the high temperature

and lower or significantly reduce the service life of high chrome

brick due to the nature of high temperature change or change the

viscosity-temperature characteristics of coal, the higher the

temperature, the lower the viscosity, liquidity, the better,

erosion and penetration of brick is more serious, the greater the

erosion rate, the lower the service life, after long-term research

and use the results of statistical, above the appropriate operating

temperature, every 100 ℃, and increased erosion rate of high chrome

brick increases by 4 times or each additional 44 ℃,The erosion rate

of bricks doubles.

The operating temperature is related to the ash melting point and

viscosity of coal cinder, and the ash melting point and viscosity

of coal cinder are directly related to the coal quality of raw

coal.The research and practice at home and abroad think that the

appropriate operating temperature should be higher than the cinder

ash melting point of about 50℃ or higher than the optimal slag

viscosity melting temperature of 20 ~ 50℃.The ash melting point of

cinder should be lower than 1300℃, and it is best to control it at

1250-1300℃.The viscosity should also be controlled within an

appropriate range of 15 ~ 25Pa·s, which can not only ensure that

the slag forms an effective protective layer on the working

surface, but also maintain a certain fluidity and do not block the

slag discharge port.The viscosity at the appropriate operating

temperature is best controlled between 25 and 35Pa·s.

As the consumption layer of high temperature resistance, erosion

resistance and erosion resistance, high purity chromium oxide

material is generally selected, commonly called

chromium-aluminum-zirconium brick or high chromium brick. It is

required that this part of refractory material has excellent high

temperature resistance, high creep resistance strength, thermal

shock stability and high temperature chemical stability.In the

process of use, the main damage factors of high chromium brick for

gasifier are as follows:

(1) chemical erosion

The high chromium brick is mainly eroded by slag, followed by the

strong reducing gas in the furnace.In addition, SiO2 and CaO in the

slag strongly permeate into the brick and react with the refractory

components to form a thicker metamorphic layer.The erosion of high

chromium brick by CO, H2 strong reducing gas is mainly caused by

the gas and impurities in the brick, such as SiO2, iron-containing

oxides reaction to generate gas overflow or under the action of

iron oxides reaction with CO to generate C deposition in the brick,

resulting in high chromium brick bulging and cracking.

(2) mechanical wear

Mechanical wear is mainly caused by scouring of high chromium brick

used in gasifier by high speed gas and carrying slag.The

consequence of this scouring is that on the one hand, the chemical

reaction between slag and high chromium brick is accelerated, on

the other hand, the reaction products of low melting point will be

taken away from the brick surface, and on the other hand, the

process of spalling of the metamorphic layer and crack site of

brick is accelerated.

(3) Operating conditions

The operation technology of gasifier is also the key factor that

causes the damage of high chromium brick.

A) Operating temperature: it has been proved by practice that for

every 100℃ increase in gasifier operating temperature, the

corrosion loss rate of firebrick may increase by nearly 3-4 times.

B) Type of coal: the ash melting point of coal determines the

operation temperature of gasifier.If the melting point of raw coal

ash is too low, the viscosity of coal ash is very small under

production conditions, which will aggravate the erosion and

penetration of molten slag to hot-faced brick.The coal with high

ash melting point often introduces certain additives, such as CaO

and Fe2O3, to reduce its melting flow temperature to the best value

when preparing CWS. But with the increase of CaO and Fe2O3, the

erosion of high chromium brick also intensifies.

C) Production load and times of start and stop: according to

statistics, the service life of hot brick decreases by 33% for each

increase of production load by 30%;Usually every time the furnace

is started and stopped, the corrosion loss of hot face brick is

5-20mm, especially when the CaO content in slag is high.

D) Burner: the experimental study and the actual field operation

show that the normal injection Angle of the burner should be about

35°, if the Angle is too large, it will cause serious scour and

spalling in the upper part;If the injection Angle is too small, it

can not be completely gasified, resulting in lower gasification

efficiency.If the burner is offset, the local erosion of furnace

lining will be aggravated.

.

Packaging

1. 1 ton bags in container, 25 MT/20'FCL.

2. 25kg bags in container, 25 MT/20'FCL

3. 25kg bags in ton bags, then in container, 25 MT/20'FCL

4. as the customer' request

Packaging of SK37 High Alumina Refractory Brick

1.on wooden pallets with plastic cover: wooden pallet size :930*930

or 1000*1000mm,

2.Load weight of each pallet: 1.5-2.0 tons,

Shipping of SK37 High Alumina Refractory Brick

1.Our packaging is as per customer’s request

2.Normal goods delivered by sea transport

3.Sample shipping by express

4.We will shipping and delivery goods timely, quality and quantity

guaranteed, and also in accordance with the contract and customer's

requirement completely.

Delivery:

15-30 days working day for large quantity. The shipment we will

arrange as soon as possible. Of course, if it is a custom products,

the shipping time will delay.

Sample:

Usually by EMS, DHL, UPS, TNT, FedEx. Anyway you like. Bulk order: Usually by sea.

Payment:

It can be through T/T, L/C at sight. The specific terms determined

according to the quantity of the goods, etc.

Your inquiry related to our product & price will be replied

within 24 hours.

Export:

Our products have been exported to many countries: Australia,

Chile, USA, Russia, UK, Indonesia, etc., good quality have be

approved by our clients.

1.Timely response,

Timely response to your inquiry, multiple choice recommendations based on your demand,quickly respond mails and provide solutions.

2.Free sample of dry ramming mass

Sample and trial order are accepted for the quality evaluation

3.Strict quality control

Arrange production on time and control quality strictly.

4.Shorter delivery time.

Book the earliest vessel or plane to guarantee the delivery time.

5.Professional Services

Provide all the detailed news and pictures from order to delivery;offer relative export documents and original certificate if needed;warm and considerable after-sale service.

Henan hongtai kiln refractory co., LTD. : "quality first, reputation first, customer first: it is our

aim."Scientific management, strong technical force, perfect testing

means, advanced technological equipment and stable product quality

are the guarantee of quality service.Henan hongtai kiln

refractories co., LTD sincerely hopes to cooperate with you hand in

hand and in good faith.

Henan hongtai kiln refractory co., LTD. Main products are high alumina brick, clay brick, fused zirconium

corundum brick, fireproof ball lightweight insulation brick,

wear-resistant pouring material, corundum pouring material, low

cement high strength pouring material, impermeable material,

self-flowing material, plastic material, and various types of

refractory materials.For different industries, the cement industry

with anti-flaking high-alumina bricks, alkali resistant bricks,

phosphate bricks;Boiler industry USES all kinds of brand

wear-resisting brick, corundum brick, mullite brick and other

finalizing materials.The company insists on "product quality is the

life, enterprise integrity is the foundation", in the fierce market

competition, won many users' trust and praise.The products are sold

all over the country, as far as Vietnam, India, Korea, Pakistan,

kazakhstan, other southeast Asian countries and regions.