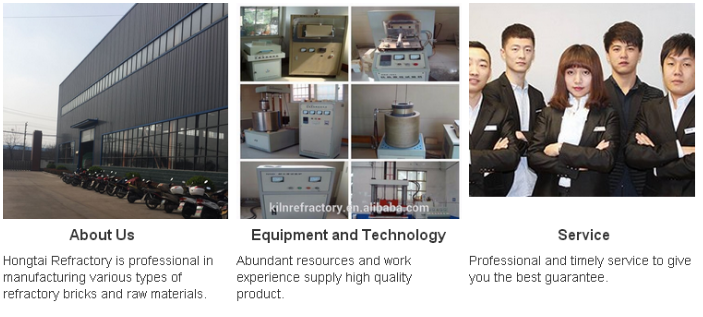

1.Strong professional:

Our company has thirty years producing experience in refractory

products. Our manager will supervise on a various refractories

production materials, process control, quality supervision and

package delivery, and ensure the products are 100% qualified.

2.Annual supply:

Our company has passed ISO 9001 quality management system

certification and SGS certification. And the annual supply of

shaped and unshaped refractory product is 28, 800-35, 000 tons.

3.Export experiences:

Now we have gained a global sales network reaching Russia, South

Korea, Vietnam, Pakistan, Bulgaria, France, India, Egypt, Congo,

Angola, South Africa etc.

4. Production equipment:

Production and testing equipment are new, complete and automated or

semi- automated. Such modern facilities and equipment have provided

the fine technical guarantee for the production and testing.

5. Testing equipment:

Our company's testing equipment as follows:

High Temperature RUL. Tester

Bulk Density Tester

The Pressure Tester

Refractoriness Tester

Our competitive Advantage:

1.Competitive Price. Make the products competitive in your market.

2.Quick Response:We promise quick response at the very first moment

when we received your request. 3.Superior Customer Service:The

company provides after sales service ensuring customer’s

satisfactions,we believe in Long term partnership bringing loyalty.

4.We had been on this filed for many years and we have our own

research team,the production process could be controlled strictly.

5.We have developed stable customer base overseas and kept

long-term cooperation.