Yong Xing Boiler Group Co.,Ltd |

|

Gas steam boilers vertical oil gas small steam boiler 200kgs/h for paper industry

Product introduction of oil gas small steam boiler :

Oil and gas Gas steam boilers: small steam boiler heated by oil and gas combustion.

Our company's vertical small steam boiler adopts the lower burner mode, two-return structure, full fuel combustion, stable boiler operation and small space occupation. At the same time, the spoiler is inserted in the smoke pipe to slow down the exhaust speed and increase the heat exchange capacity. High thermal efficiency of boiler, reducing user's use cost

Our vertical Oil and gas small steam boiler principle:

1. Oil and Gas steam boilers are a thermal energy conversion device that uses natural gas, liquefied gas, city gas and other gas fuels as fuel, burns the heat released in the furnace, heats the water in the boiler, and vaporizes it into steam.

2. Water in the drum is constantly heated by the energy released by the combustion of gaseous fuel in the furnace to heat up the temperature and generate pressurized steam. Because the boiler is sealed, the boiling point of water rises with the increase of pressure, and the expansion of water vapor in the drum is limited, which generates pressure to form hot steam.

3. In fact, the water vapor of the boiler is formed by heating the water in the drum to a saturated pressure and then vaporizing it.

Product Features of Gas steam boilers:

1. The burner of the gas steam boilers is supplied by a world-renowned manufacturer. It automatically burns and stops according to the instructions of the controller. The independent program controller has multiple safety protections, safe and stable performance, and low maintenance rate.

2. Advanced automatic controller for steam boiler, full Chinese LCD screen, man-machine interface, users only need to easily set, the boiler can start and stop, load adjustment, automatic water supply, and other automatic operations according to user requirements. The boiler has complete functions, complete protection, simple operation, safety and reliability, and self-diagnostic function. Once an abnormal phenomenon occurs during the operation of the boiler, the combustion is automatically interrupted, and an audible and visual alarm is issued.

3. Multi-level interlock protection for boiler safety:

Pressure switch protection: automatic shutdown and alarm when the pressure is higher than the set pressure,

Low water level protection: the water level in the boiler body is lower than the warning water level, automatically cut off the power and alarm,

Safety valve protection: The boiler pressure exceeds the working pressure, and the gas is automatically vented and reduced to ensure that the boiler is safe and stable under various operating conditions.

4, stainless steel shell packaging, mechatronics appearance, exquisite and novel, compact structure, less space, convenient transportation and installation.

5. It adopts a new type of thermal insulation materials and full stainless steel packaging, light weight, good thermal insulation performance, beautiful and generous, not easy to rust.

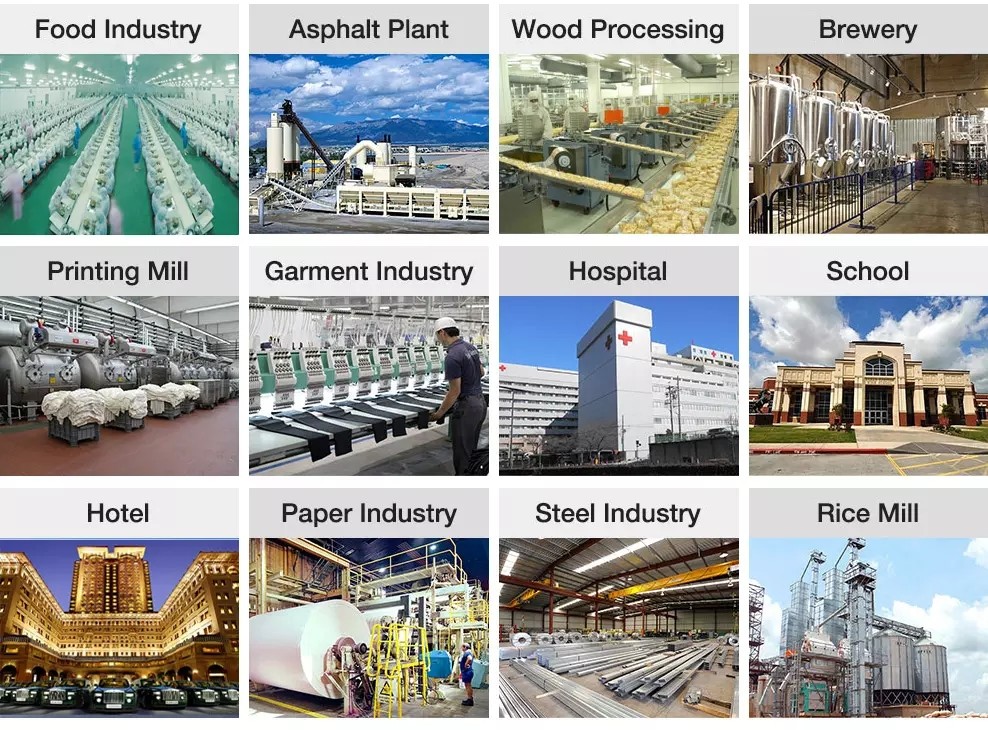

6. Automatic gas steam boilers are widely used in

hospitals, schools, textile factories, clothing factories, clothing supermarkets, clothing factories, dry cleaners, restaurants, hotels, restaurants, hotels, canteens, restaurants, food factories, beverage factories, Bean products factory, meat products factory, a canning factory, winery, pharmaceutical factory, packaging factory, building material factory, paint factory, beauty salon, bath center, sauna, steam room, baby swimming pool, and other industries

Vertical Steam Boiler Technical Parameters:(The model also had 0.1 ton)

| LHG series wood pellets boiler steam generator technical parameters | |||||||

| model | LHG0.2-0.7 | LHG0.3-0.7 | LHG0.5-0.7 | LHG0.7-0.7 | LHG1-0.7 | ||

| Evaporation (t / h) | 0.2 | 0.3 | 0.5 | 0.7 | 1 | ||

| Quota steam pressure (Mpa) | 0.4 / 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | ||

| Steam temperature (℃) | 150/170 | 170 | 170 | 170 | 170 | ||

| Water temperature (℃) | 20 | ||||||

| Thermal efficiency(%) | ≥95 | ||||||

| Heat transfer area (m2) | 7.2 | 10.8 | 16.5 | 23.4 | 34.1 | ||

| Applicable fuel | coal/wood/biomass and other | ||||||

| Fuel consumption | Diesel (kg / h) | 13.5 | 18.32 | 30.94 | 46 | 67 | |

| Natural gas (m3 / h) | 16 | 22 | 37.3 | 55.7 | 72 | ||

| Liquefied gas (m3 / h) | 12.5 | 18 | 31.3 | 41.8 | 62 | ||

| City gas (m3 / h) | 30 | 44 | 75 | 98 | 156 | ||

| Air supply pressure (Mpa) | 3/5/2020 | 3/6/2020 | 4/8/2020 | 5/8/2020 | 6/10/2020 | ||

| Steam caliber (DN) | 25 | 25 | 40 | 40 | 50 | ||

| Chimney diameter (DN) | 219 | 219 | 273 | 273 | 325 | ||

| Power consumption (KW) | 0.85 | 1.1 | 1.3 | 1.5 | 1.7 | ||

| Water capacity of pipe group (kg) | 25 | 29 | 29 | 29 | 29 | ||

| Dimensions | Length (mm) | 1300 | 1400 | 1600 | 1800 | 1800 | |

| Width (mm) | 1150 | 1250 | 1450 | 1650 | 1650 | ||

| Height (mm) | 2400 | 2500 | 2500 | 2600 | 2800 | ||

OIL GAS fired vertical steam boiler, gas steam boilers technical datasheet:

| Model Item | LHS0.1-0.4-Y(Q) | LHS0.2-0.4-Y(Q) | LHS0.3-0.4-Y(Q) LSS0.3-0.7-Y(Q) | LHS0.5-0.4-Y(Q) LSS0.5-0.7-Y(Q) | LHS0.7-0.4-Y(Q) LSS0.7-0.7-Y(Q) | LHS1-0.4-Y(Q) LSS1-0.7-Y(Q) |

| Rated evaporation capacity (t/h) | 0.1 | 0.2 | 0.3 | 0.5 | 0.7 | 1 |

| Working pressure(Mpa) | 0.4 | 0.4 | 0.4/0.7 | 0.4/0.7 | 0.4/0.7 | 0.4/0.7 |

| Rated steam temperature(°C) | 151 | 151 | 151/170 | 151/170 | 151/170 | 151/170 |

| Feed water temperature(°C) | 20 | 20 | 20 | 20 | 20 | 20 |

| Heating area (m2) | 3 | 3 | 3 | 3 | 3 | 3 |

| Thermal Efficiency(%) | 89 | 89.2 | 89.5 | 89.6 | 91 | 91 |

| Size(m) | 0.8x 1.94 | 0.9x 2.7 | 1.2x 2.58 | 1.3x 2.95 | 1.6x 3.0 | 1.5x 3.2 |

| Weight (t) | 0.83 | 1 | 1.28 | 2.1 | 3.5 | 4.1 |

Transport & Delivery

Vertical Steam Boiler FAQ:

Dear friend,

Thanks for your time for scanning our products.

We need the following information to confirm the boiler model:

1.Boiler type: Vertical Steam Boiler

2.Boiler capacity?

3. Boiler pressure?

4. Boiler application?

After confirming these questions, we will know exactly what boiler

will be suitable for you and we will provide you our product

details and quotation. Thank u.

It is ok to copy the question and answers directly when sending us

the inquiry!

Welcome you any time!