Yong Xing Boiler Group Co.,Ltd |

|

0.5 t/h vertical wood pellet small biomass boiler for Philippines

Vertical Steam Boiler Introduction:

1. LHG type vertical automatic Vertical Steam Boiler is a tubular structure, the whole machine control process is simple and accurate, high thermal efficiency, short preheating time, using a circular arc structure, so that the exchange of cold and heat is even, more high-speed to achieve the set pressure.

2. The steam pressure can reach 0.4mpa within 5-8 minutes after starting the machine. The one-click start button can be used to control the machine, and the machine can be started up and run automatically for up to 4 periods.

3. The equipment is equipped with automatic water addition, pressure control, water shortage protection and alarm, automatic shutdown of the furnace at very low water level, overpressure protection, overpressure safety valve and other protective measures.

4. Built-in steam separation output device to ensure the quality of steam output.It can also produce continuous steam in a short period of time.

5. Steam output can be stabilized in cold water for 5 minutes, and steam supply can be stabilized in hot water for 5 seconds.

6. Equipped with a patented water refill buffer, so that there is no significant pressure fluctuation in the process of refill.

7. Shortened working hours and improved working efficiency.

Vertical Steam Boiler working principle:

The main working principle of small biomass boiler is a kind of heat equipment which uses the heat energy released after fuel combustion or the waste heat in industrial production to transfer to the water in the container so that the water can reach the required temperature or certain pressure steam.

Boiler in the "pot" and "furnace" two parts at the same time, water into the boiler, our vertical small biomass boiler, in the steam system boiler heating surface will absorb the heat transfer to the water supply, so that the water heated to a certain temperature and pressure of hot water or steam generation, is drawn out for application.

1. Vertical small biomass boiler adopts the mode of combustion machine down, vertical steam generator, two-return structure, full fuel combustion, stable operation of the boiler;

2. A spoiler is inserted in the smoke pipe to slow down the exhaust speed, increase the heat exchange, high thermal efficiency of the boiler, and reduce the user's use cost.

4. A small biomass boiler is an energy converter, which uses the heat energy or other heat energy released by fuel combustion to heat working water or other fluids to a certain parameter.

5. The hot water or steam generated in the boiler can directly provide the required heat energy for industrial production and people's life, and can also be converted into mechanical energy through the steam power plant or into electrical energy through the generator.

6. The small biomass boiler often referred to as boiler for short, mostly used in thermal power stations, ships, locomotives and industrial and mining enterprises.

The performance characteristics:

1. Fully automatic operation, no black smoke, safety, environmental protection and efficiency.

2. Set water level, overpressure protection, water shortage protection in one.

3. Small size, easy installation and operation, one-button start.

4. Run for a few minutes to produce a continuous stream of steam.

5. The boiler water volume is small, so there is no need to report to the boiler inspection office for inspection.

6. Perfect protection system: boiler overpressure interlocking protection device, controller alarm, burner stop operation, automatic sewage start, safety valve open.

7. Energy saving and high efficiency, the thermal efficiency is 95%, 45%-65% energy saving compared with the traditional steam cabinet.

8. China Country standard GB3087 steel tube for boiler, long service life.

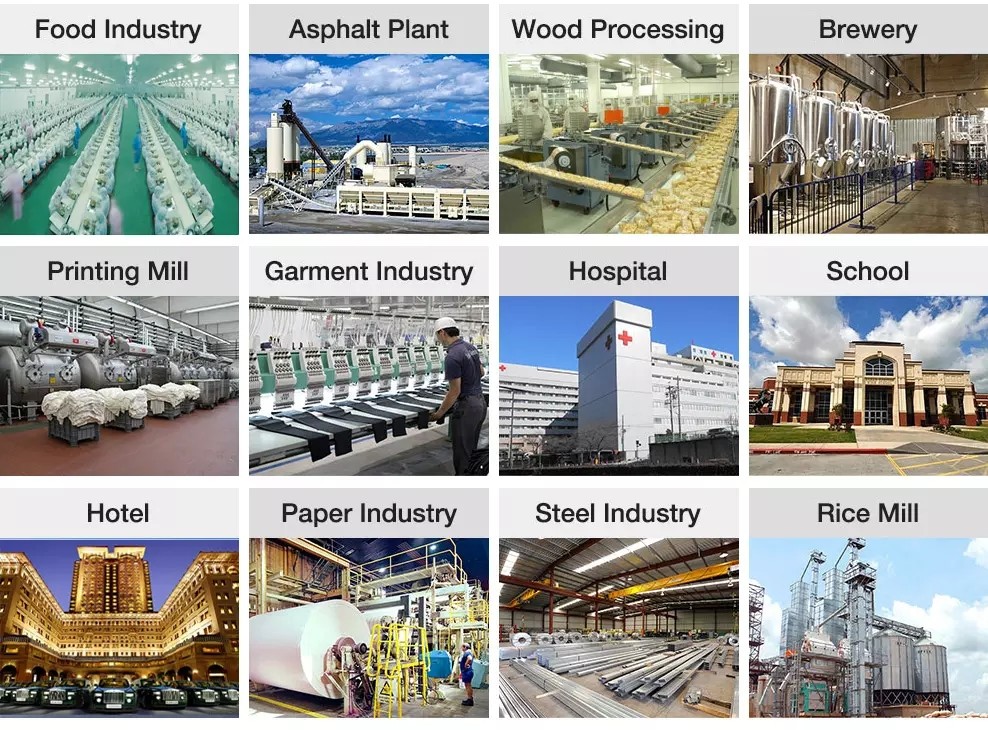

Follow is the wood pallets boiler applicable:

Vertical Steam Boiler Technical Parameters:(The model also had 0.1 ton)

| LHG series wood pellets boiler steam generator technical parameters | |||||||

| model | LHG0.2-0.7 | LHG0.3-0.7 | LHG0.5-0.7 | LHG0.7-0.7 | LHG1-0.7 | ||

| Evaporation (t / h) | 0.2 | 0.3 | 0.5 | 0.7 | 1 | ||

| Quota steam pressure (Mpa) | 0.4 / 0.7 | 0.7 | 0.7 | 0.7 | 0.7 | ||

| Steam temperature (℃) | 150/170 | 170 | 170 | 170 | 170 | ||

| Water temperature (℃) | 20 | ||||||

| Thermal efficiency(%) | ≥95 | ||||||

| Heat transfer area (m2) | 7.2 | 10.8 | 16.5 | 23.4 | 34.1 | ||

| Applicable fuel | coal/wood/biomass and other | ||||||

| Fuel consumption | Diesel (kg / h) | 13.5 | 18.32 | 30.94 | 46 | 67 | |

| Natural gas (m3 / h) | 16 | 22 | 37.3 | 55.7 | 72 | ||

| Liquefied gas (m3 / h) | 12.5 | 18 | 31.3 | 41.8 | 62 | ||

| City gas (m3 / h) | 30 | 44 | 75 | 98 | 156 | ||

| Air supply pressure (Mpa) | 3/5/2020 | 3/6/2020 | 4/8/2020 | 5/8/2020 | 6/10/2020 | ||

| Steam caliber (DN) | 25 | 25 | 40 | 40 | 50 | ||

| Chimney diameter (DN) | 219 | 219 | 273 | 273 | 325 | ||

| Power consumption (KW) | 0.85 | 1.1 | 1.3 | 1.5 | 1.7 | ||

| Water capacity of pipe group (kg) | 25 | 29 | 29 | 29 | 29 | ||

| Dimensions | Length (mm) | 1300 | 1400 | 1600 | 1800 | 1800 | |

| Width (mm) | 1150 | 1250 | 1450 | 1650 | 1650 | ||

| Height (mm) | 2400 | 2500 | 2500 | 2600 | 2800 | ||

OIL GAS fired vertical steam boiler, steam generator technical datasheet:

| Model Item | LHS0.1-0.4-Y(Q) | LHS0.2-0.4-Y(Q) | LHS0.3-0.4-Y(Q) LSS0.3-0.7-Y(Q) | LHS0.5-0.4-Y(Q) LSS0.5-0.7-Y(Q) | LHS0.7-0.4-Y(Q) LSS0.7-0.7-Y(Q) | LHS1-0.4-Y(Q) LSS1-0.7-Y(Q) |

| Rated evaporation capacity (t/h) | 0.1 | 0.2 | 0.3 | 0.5 | 0.7 | 1 |

| Working pressure(Mpa) | 0.4 | 0.4 | 0.4/0.7 | 0.4/0.7 | 0.4/0.7 | 0.4/0.7 |

| Rated steam temperature(°C) | 151 | 151 | 151/170 | 151/170 | 151/170 | 151/170 |

| Feed water temperature(°C) | 20 | 20 | 20 | 20 | 20 | 20 |

| Heating area (m2) | 3 | 3 | 3 | 3 | 3 | 3 |

| Thermal Efficiency(%) | 89 | 89.2 | 89.5 | 89.6 | 91 | 91 |

| Size(m) | 0.8x 1.94 | 0.9x 2.7 | 1.2x 2.58 | 1.3x 2.95 | 1.6x 3.0 | 1.5x 3.2 |

| Weight (t) | 0.83 | 1 | 1.28 | 2.1 | 3.5 | 4.1 |

Transport & Delivery

Vertical Steam Boiler FAQ:

Dear friend,

Thanks for your time for scanning our products.

We need the following information to confirm the boiler model:

1.Boiler type: Vertical Steam Boiler

2.Boiler capacity?

3. Boiler pressure?

4. Boiler application?

After confirming these questions, we will know exactly what boiler

will be suitable for you and we will provide you our product

details and quotation. Thank u.

It is ok to copy the question and answers directly when sending us

the inquiry!

Welcome you any time!