CHENGDU ZK SEPARATION TECHNOLOGY CO., LTD. |

|

Slag Dewatering Hazardous Waste Disposal Horizonta Decanter Centrifuge

Solid-Liquid Separation Of Hazardous Waste Disposal Systems

Hazardous wastes refer to the wastes with hazardous characteristics that are listed in the National Hazardous Waste List according to the Law of the People's Republic of China on the Prevention and Control of Environment Pollution Caused by Solid Wastes, or dangerous wastes determined using the state prescribed standards and methods for identification of hazardous wastes.

With the development of industry, the amount of hazardous wastes discharged from industrial production is increasing. It is estimated that the annual amount of hazardous wastes generated worldwide is 330 million tons. Due to the serious pollution and potential grave impacts of hazardous wastes, the hazardous wastes in industrially advanced countries have been called “political wastes”. The public is sensitive to hazardous wastes and opposes the establishment of hazardous waste disposal sites in their living areas. The disposal of hazardous wastes is expensive, and some companies are trying to transfer hazardous wastes to industrially underdeveloped countries and regions.

Two-phase centrifuge model and technical parameters

| Centrifuge model | mm Drum diameter mm | Length-diameter ratio | Separation factor | rpm Differential speed rpm | kW Main motor power kW | kW Ancillary motor power (kW) | m3/h Throughput m3/h | kg Weight (kg) | mm Boundary dimension mm (L x W x H) |

| LW250×1025B | 250 | 4.1 | 3500 | 1-50 | 7.5-11 | 3 ~4 | 1~2 | 1150 | 2300×750×1100 |

| LW350×1435B | 350 | 4.1 | 3136 | 1-35 | 15-22 | 4-5.5 | 3~5 | 2500 | 3400×900×1400 |

| LW450×1845B | 450 | 4.1 | 2580 | 1~34 | 30-37 | 7.5-11 | 5~10 | 4000 | 4500×1000×1400 |

| LW520×2150B | 520 | 4.1 | 2620 | 1~30 | 45-55 | 11-18.5 | 10-15 | 5600 | 5100×1250×1500 |

| LW580×2400B | 580 | 4.1 | 2546 | 1~30 | 55-75 | 15-18.5 | 15-20 | 6500 | 5300×1300×1750 |

| LW650×2600B | 650 | 4 | 2460 | 1~28 | 75-90 | 18.5-22 | 20-30 | 7800 | 5100×1550×1400 |

| LW750×2800B | 750 | 3.7 | 2032 | 1~55 | 110-132 | 22-30 | 30-40 | 9000 | 6000×3250×1500 |

Note: The throughput is related to material characteristics;

II. Hazardous waste treatment process

Gasification melting process is adopted. The system comprises feeding and preparing device + gasifier + secondary combustion chamber + residual heat exchanger (SNCR) + chiller + bag dust remover + alkali eluting sulfur tower + wet electrostatic precipitator + flue gas heat exchanger +flue gas burner+low temperature SCR + induced draft fan + chimney. The treated flue gas is discharged into the atmosphere through the chimney to ensure that the concentration and discharging rate of gases polluting the environment are lower than the standard emission requirements.

The working principle is that the hazardous waste enters the gasification furnace after pretreatment, and is subjected to pyrolysis and gasification under an anoxic reducing condition. After that, the gasified product enters the melting furnace for high-temperature combustion to generate glassy slag. Compared with conventional incineration, the gasification and melting technology is completely harmless and remarkable in capacity reduction, and recovers energy and by-products.

III. Core equipment of gasification slag dewatering – centrifuge

★ Fully automatic control mode

Programmatic automatic control mode from start to separation to cleaning to stop reduces human intervention during the operation of the equipment and lowers the requirements on operator quality; the intelligent control mode together with sensors for measuring vibration and temperature and speed has improved the capability to predict and solve equipment operation failures.

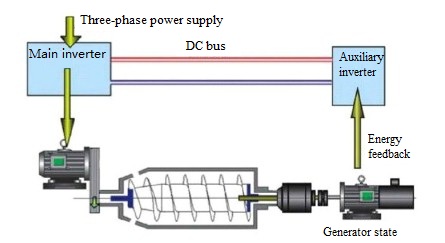

★ Double-motor double-frequency conversion common DC bus

The main and ancillary motors of the centrifuge are controlled by a high-performance vector inverter. The ancillary motor is always in the generator state under the differential speed. The inverter adopts common DC bus technology. The auxiliary inverter can convert the electric energy generated by the ancillary motor into the power source to drive the main motor, thereby achieving the purpose of energy conservation.

Through the double-motor double-frequency conversion control technology, the stepless adjustment of the centrifuge differential speed can be realized. It features fast reaction speed, accurate torque detection, stable torque control, and low failure rate.

V. Applications

Solid-liquid separation realized by using a high-efficiency LW

series two-phase centrifuge can reduce the liquid content of the

slag phase, facilitate transportation, and increase the combustion

heat value.

Separation performance:

The water content of the slag phase after centrifugation can be ≤55, and its total volume is reduced by over 80% compared to that before separation;

The solid content of the liquid phase after separation can reach

≤0.1~0.2%;