HENAN HONGJI MINE MACHINERY CO.,LTD |

|

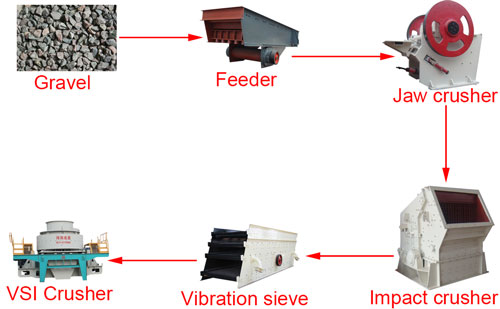

Vibrating Feeder->Jaw Crusher->Impact Crusher->Vibrating Screen->VSI Crusher

1) Feeding: The material is loaded into the vibrating feeder by the

forklift, and the gravel is evenly conveyed into the crusher by the

vibrating feeder.

2) Crushing: the stone is crushed by a jaw crusher, and the impact

crusher is crushed and then transferred into the vibrating screen.

3) Screening: After the sieve is sieved out of the gravel of 40mm

or less, it is sent into the sand making machine, and more than

40mm is re-crushed.

4) Sand making: gravel below 40mm is broken into sand in sand

making machine

Broken small rock, its size, shape, and texture are irregular. It may be caused by natural causes or by artificial destruction.

Mining, building materials, water conservancy, transportation, chemicals, etc.

Impact crusher parameter

| Model | PF-1007 | PF-1010 | PF-1315 | PF-1320 |

| Specifications(mm) | Φ1000×700 | Φ1000×1050 | Φ1300×1500 | Φ1300×2000 |

| Input port size(mm) | 400×730 | 400×1080 | 680×1520 | 680×1570 |

| Input size(mm) | 300 | 350 | 350 | 350 |

| Capacity(t/h) | 35-50 | 50-80 | 90-220 | 110-350 |

| Power Model | Y250M-6 | Y315S-6 | Y2-355M2-6 | Y2-355M2-6 |

| Power(kw) | 37 | 75 | 200 | 280 |

| Weight(t) | 9.5 | 14 | 26 | 28 |

| Length*width*high (mm) | 1800×1600×1800 | 2340×2007×2500 | 2930×2761×3053 | 3340×2950×3000 |

jaw crusher parameter

| Model | PE1500×1800 | PE1200×1500 | PEX150×750 | PEX150×250 |

| Input size (mm) | 1500×1800 | 1200×1500 | 150×750 | 150×250 |

| Input (mm) | ≤1200 | ≤1020 | ≤125 | ≤125 |

| Output size (mm) | 210~360 | 150~300 | 18~48 | 10~40 |

| Capacity (t/h) | 520~1100 | 400~800 | 5~16 | 1~3 |

| Power (kw) | 280 | 160~220 | 15 | 5.5 |

| Weight (t) | 132 | 100.9 | 3.8 | 1.5 |

| Size (mm) | 7460×6235×4249 | 6380×5310×3710 | 1200×1500×1200 | 896×745×935 |

VSI crusher

| Model | VSI6X1263 | VSI6X1150 | VSI6X1040 | VSI6X9026 | VSI6X8018 |

| Sand making | ≤50 | ≤45 | ≤40 | ≤35 | ≤30 |

| Stone shaping | ≤60 | ≤55 | ≤50 | ≤45 | ≤40 |

| Sand making | 454-486 | 344-368 | 264-283 | 167-179 | 109-117 |

| Stone shaping | 545-583 | 413-442 | 317-342 | 200-215 | 131-140 |

| Speed(r/min) | 900-1200 | 1000-1300 | 1100-1400 | 1200-1500 | 1300-1700 |

| Power(kw) | 315×2 | 250×2 | 200×2 | 132×2 | 90×2 |

1) The equipment is of good quality and the production process is

safe and secure.

2) High equipment output

3) Manufacturers provide free design drawings

1) Cash on delivery

2) Technical engineers assist users put into production smooth

3) After the equipment arrives at the scene, the engineer arrives

at the scene within 24 hours.

Each crusher processing equipment manufacturer costs differently and the price is different. If you want to know the price of the equipment, you can contact us.