Guangyuan Technology (HK) Electronics Co., Ltd. |

|

Verified Suppliers

|

|

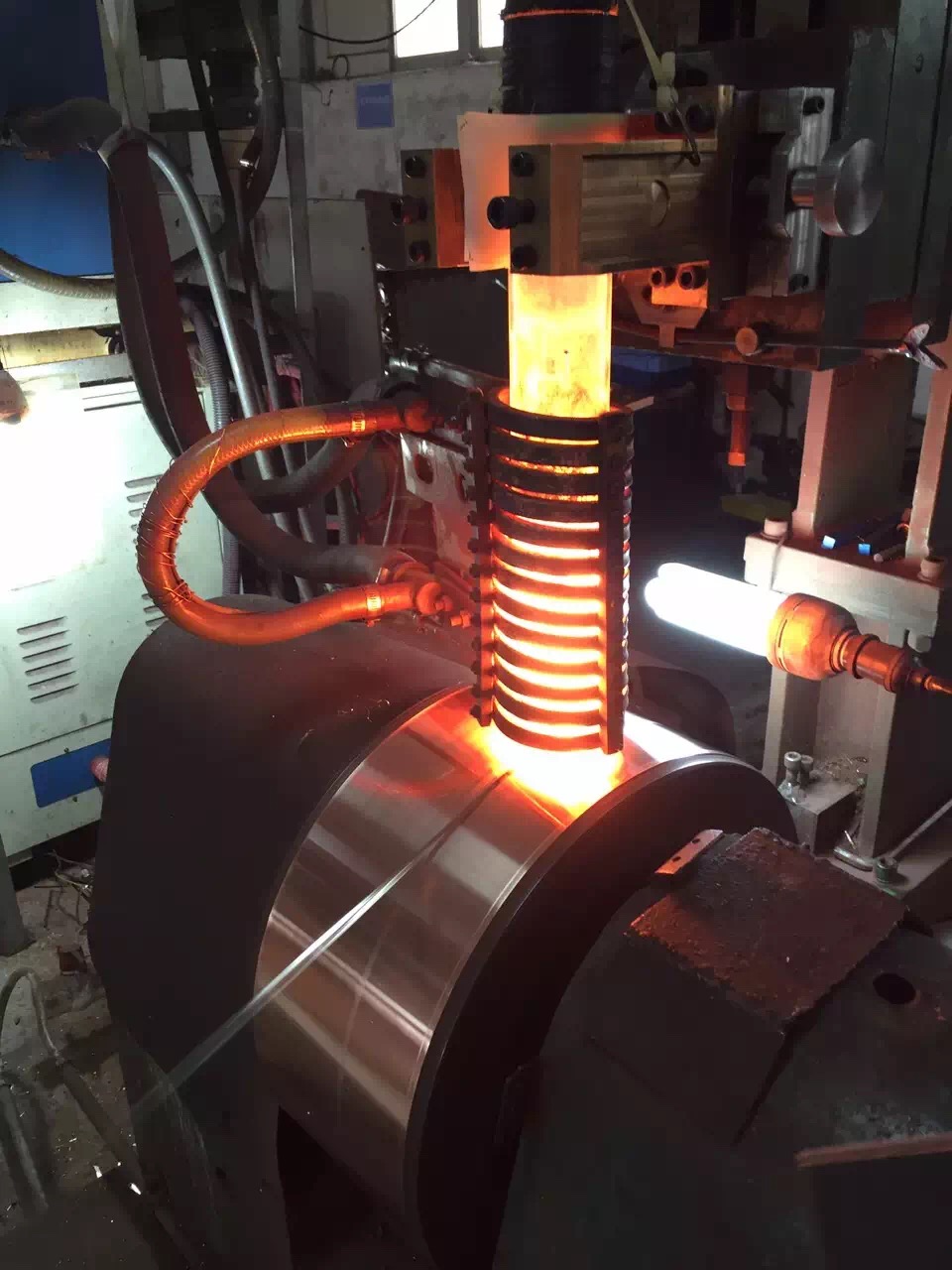

Revolutionize your metalworking processes with our cutting-edge induction melting machine. Powered by state-of-the-art electromagnetic technology, it delivers exceptional results by generating heat directly within the workpiece. This innovative approach allows for quick and uniform melting of materials, resulting in significant energy savings and superior temperature control.

Our induction melting machine is the go-to solution for industries in need of efficient and precise heating. With user-friendly controls and a wide range of applications, it caters to the diverse needs of modern workshops. Experience improved product quality, increased productivity, and cost-effectiveness with our advanced heating solution.

Induction melting machines are powerful industrial heating devices designed for efficient and speedy melting of metals. By utilizing electromagnetic induction, these machines can rapidly heat and melt electrically conductive materials. Some essential characteristics of an induction melting machine include:

| Technical Parameters | Induction Melting Machine |

|---|---|

| Safety System | Emergency Stop/Interlock/Ground Fault |

| Display System | Touch Screen |

| Melting Furnace | Crucible |

| Heating Mode | Induction Heating |

| Control System | IGBT System |

| Protection System | Over-Current/Over-Voltage/Over-Temperature/Short-Circuit |

| Max. Melting Capacity | 1-1000kg/h |

| Max. Temperature | 1800℃ |

| Cooling Mode | Water Cooling |

| Power Supply | 220V/380V/415V/440V/480V |

Induction melting machines are a versatile solution for precise and efficient metal melting in various industrial applications. Some common uses include:

Induction melting is widely used in foundries for producing high-quality castings. This method allows for the melting of metals like aluminum, iron, and steel without the need for core or mold heating, resulting in consistent and high-quality castings.

Induction technology is also employed in recycling centers to melt down scrap metals, making them reusable for new products. This process is a cost-effective and environmentally friendly way to recycle metal.

Precision melting of precious metals like gold, silver, and platinum is achieved using induction melting machines in jewelry making. This allows for the creation of consistent alloys, essential for producing high-quality jewelry.

Induction heating is crucial for brazing and soldering operations, providing the necessary heat for strong and uniform joints in metalwork. This method is widely used in various industries, including automotive, aerospace, and medical.

Induction melting machines are also used in heat treatment processes, where a material's surface is rapidly heated and then quenched to increase its hardness. This is commonly employed in manufacturing components for machinery and equipment.

The controlled heating provided by induction melting is ideal for forging processes, as it allows for metal to be shaped while in a heated and more pliable state. This method is used in the production of hardware, tools, and other metal components.

Induction melting is a crucial step in the investment casting process. This involves melting metal in an induction furnace and pouring it into precision-made ceramic shells to create complex shapes with high dimensional accuracy.

In the glass industry, induction melting is used to melt glass for forming or shaping before cooling and solidifying. This process is essential for creating products like bottles, jars, and windows.

Induction heating is widely used in electronics manufacturing for soldering electronic components or removing unwanted materials from circuit boards through a process known as desoldering.

These are just some of the many applications that demonstrate the broad utility of induction melting machines in various industries that require high-quality metalworking and processing capabilities.