Guang Yuan Technology (HK) Electronics Co., Limited |

|

Verified Suppliers

|

|

High Frequency IGBT Induction Heating Machine For Bolt Forging

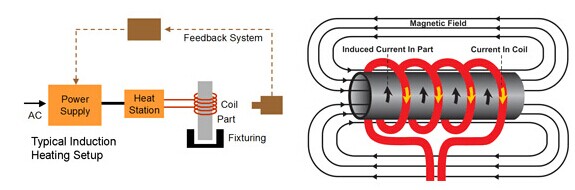

Induction heating is the process of heating an electrically conducting object (usually a metal) by electromagnetic induction, through heat generated in the object by eddy currents. An induction heater consists of an electromagnet and an electronic oscillator that passes a high-frequency alternating current (AC) through the electromagnet. The rapidly alternating magnetic field penetrates the object, generating electric currents inside the conductor, called eddy currents. The eddy currents flowing through the resistance of the material heat it by Joule heating. In ferromagnetic (and ferrimagnetic) materials like iron, heat may also be generated by magnetic hysteresis losses. The frequency of current used depends on the object size, material type, coupling (between the work coil and the object to be heated) and the penetration depth.

Induction Heating Machine GY-40AB Parameter

| Model | GY-40AB (Three phase) |

| work power | 340V-430V |

| input current | 41A |

| Fluctuating output power | 40KW |

| fluctuating frequency | 30-80KHZ |

| output current | 200-1800A |

| the flow rate of cooling water | 0.08-0.16Mpa 7.6L/Min |

| water temperature protection point | 40C |

| product size | main:620x250x530mm |

| transformer:480x260x410 mm | |

| net weight | main : 34.5kgs |

| transformer : 31.5kgs |

Delivery Time: within 3 workdays.

Shipping Term:By sea,By air,by express.

Extra accessories accept choose

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

Induction Heating Work Principle

Main Applications

Big metal parts/bars/rods heating, quenching, hardening, annealing,

tempering, normalizing, copper brazing ,silver brazing etc.

All kinds of metallic materials' heating treatments:

Quenching/Hardening for big shafts, gears, standard bolts/rods/nuts

Surface hardening, induction heating hardening, steel pipe

induction heating, induction annealing machine.

Layer of about 2~3mm

Products characteristics

1. The IGBT power module is adopted, with low power dissipation and

efficient energy conservation itself.

2. Soft switching parallel resonance, and PFM double control

circuit are adopted, which is simple and easy to operate.

3. Output transformer can not only match conveniently the load

impedance, but also segregate the high voltage electricity network;

it is safe to operate.

4. The circuit is simple and reliable , and is convenient to bear

high-power capacity through the parallel connection.

5. It is designed for 100% full power, and can run around the

clock.

6. The volume is incredibly small, which can save production space

for client.

7. It is fit for the striking and forging, and smelting of all

kinds of metals, especially fit for the diathermancy of small

workpieces, which needs partial diathermancy.

Induction Heating Machine After service

Q: Why choose GuangYuan Company?

A: We are manufacture which had in this filed for nearly 20

years.No matter quality,

price,service,delivery time,we all have large advantage.

Q:How to choose suiteble machine?

A:You can tell us your application,need

forging,hardening,welding,melting or other,

pass me workpiece material & size,Temperature requirement and heating time requirement.

Then we will recommend fit machine for you reference.

Q:How about the machine payment term&delivery time&Shipping

term?

A: Our company payment term accept T/T,Western Union,L/C and so

on.Small machine delivery

time is 3~7 workdays.Big machine delivery time 15~25 workdays.Shipping term accept EXW,FOB,

CIF and so on.

Q:How about the machine warranty?

A:Our goods support one year warranty not by personal

purpose,support technical service all life.

During the warranty,if machine have problem need change spare

parts,we can replace for you charge free.

CALENTAMIENTO P/INDUCCION,HORNO DE INDUCCION,MAQUINA DE CALENTAMIENTO

LOS DEMAS APARATOS PARA TRATAMIENTO TERMICO DE MATERIAS POR INDUCCION O PERDIDAS DIELECTRICAS