JIANGSU RELIANCE THERMAL EQUIPMENT CO., LTD |

|

Verified Suppliers

|

|

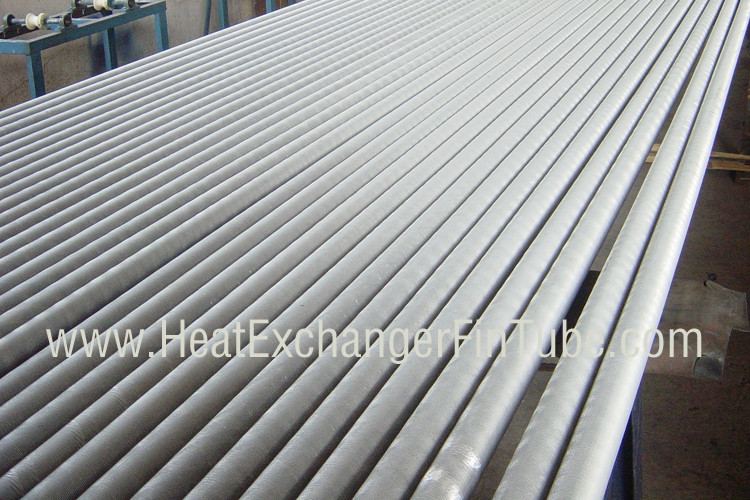

seamless cold finished mechanical extruded bimetallic finned tubes

We have fourteen extrusion fining lines, daily capacity around 15,000 meters, max. base tube OD 2''

Detail:

ASTM A192 / A192M : Seamless Carbon Steel Boiler Tubes for

High-Pressure Service

ASTM A210 / A210M : Seamless Medium-Carbon Steel Boiler and Superheater Tubes

ASTM A179 / A179M : Seamless Cold-Drawn Low-Carbon Steel Heat-Exchanger and Condenser

Tubes

Tube Type:Seamless (Cold Drawn)

Ends:Plain ends or bevel ends.

Surface protection:black painting,anti-rust oil or varnish.

| General extrusion production capacity | General specifications of Extruded Fin Tubes |

Extrusion Facility: 14 finning machines. | Tube OD: 12mm min.~50.8mm(2'') max. |

Specifications:

Extruded Bimetallic Finned Tube is combined with two different

materials.

| Items | General Materials | Popular ASTM Materials |

| Core Tube Material | Any metallic materials, as carbon steel, low-alloy steel, | 1. Carbon Steel: A179, A192,SA210 Gr A1/C,A106 Gr B |

| Fins Material | 1. Aluminum Alloy | 1. Aluminum(Alu.1100,Alu.1060,Alu.6063) |

All dimensions are in Inches and specification upon your requests. | |||

Tube OD | Fin Height | Fin Thickness | Fins per Pitch(Density) |

5/8 | 3/8,1/2 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

3/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11, 12 |

1 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11 |

1 1/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, |

1 1/2 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10, 11 |

1 3/4 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10 |

2 | 3/8,1/2,5/8 | .015/.016/ .020 | 4, 5, 6, 7, 8, 9, 10 |

Please email us for more information. | |||

Manufacturing Process

A smooth core tube is inserted into an aluminum sleeve and then the

fins are extruded out of the aluminum sleeve.

Fins Type:

The fins are solid plain or serrated into segments or as your

design.

Unfinned Section

Both plain ends with appr. 10mm~50mm and gaps (Unfinned Section) in the middle.

Surface Coating

Both bare ends of Bimetallic Finned Tubes shall be Zinc or Aluminum that metallized applied by an electro spray arc system coating.

Accessories

Tube Support Box, Clamp or Spacer Box(Materials: Aluminum, Zinc or

Stainless Steel).

Applications:

The common application fileds are: