Jiangyin M&C Heat Parts Co.,Ltd |

|

Verified Suppliers

|

|

Sondex/ Danfoss S7/S7A Heat Exchanger Plate and Rubber Gasket For

Small Size Plate Heat Exchanger

S7/S7A Plate Heat Exchanger Construction

| Frame | Plates | Gaskets |

|

|

|

S7/S7A Model Plate Heat Exchanger Specification

| Surface Area | 0.07㎡ |

| Plate Theta Angle | 55° 125° |

| Connection Diameter | 60mm |

| Plate Corrugate Thickness | 2.6 mm |

| Plate Centre Length* Width | 394*126 mm |

| Plate Shape Length*Width | 498*230 mm |

S7/S7A Plate Heat Exchanger Technical Information

| Frame |

|

| Design Pressure |

|

| Intermediate Frames |

|

| Connections |

|

| Plate Material |

|

| Gaskets |

|

| Extra Equipment |

|

S7/S7A Plate Heat Exchanger Gasket & Plate Pictures

S7/S7A Frames

| Number of Plates | L(frame length)(mm) | W(mm) | H(mm) | Weigth max,empty(kg) | Connection type |

| S7A IS16 | |||||

| 7-39 | 429 | 300(11.81") | 745(29.33") | 111 | DN50 flang or 2" threaded pipe BSP |

| 40-76 | 629 | 135 | |||

| 77-150 | 1029 | 181 | |||

| 151-206 | 1329 | 215 | |||

| 207-243 | 1529 | 240 | |||

| 244-336 | 2029 | 297 | |||

| S7A IG16 | |||||

| 7-50 | 437 | 300(11.81") | 694(27.32") | 116 | 2" threaded pipe BSP |

| 51-69 | 537 | 127 | |||

| 70-87 | 637 | 139 | |||

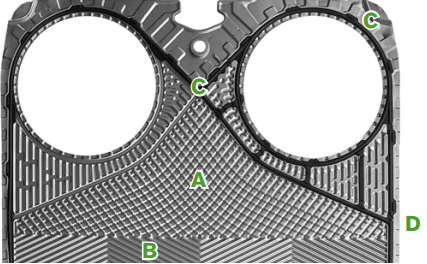

PHE Plate Feature

| FEATURE | ADVANTAGES | WHAT'S IN IT FOR YOU! | |

| A | DISTRIBUTION AREA | Efficient Flow Distribution |

|

| B | CORRUGATED PLATE PATTERN-HEAT TRANSFER AREA | Promotes Turbulence, Minimize Fouling |

|

| C | PLATE LOCKING SYSTEMS | "Corner lock" and " bubble lock" concepts ensure a stable and well aligned plate pack when the unit is closed |

|

| D | EASYCLIP GASKET SYSTEM | Bevelled gasket edges easily clip into place using your flingers Stays securely in place and provides high sealing integrity |

|

PHE Gasket Type

Please check their are three common model gasket type are aways used in Sondex brand.

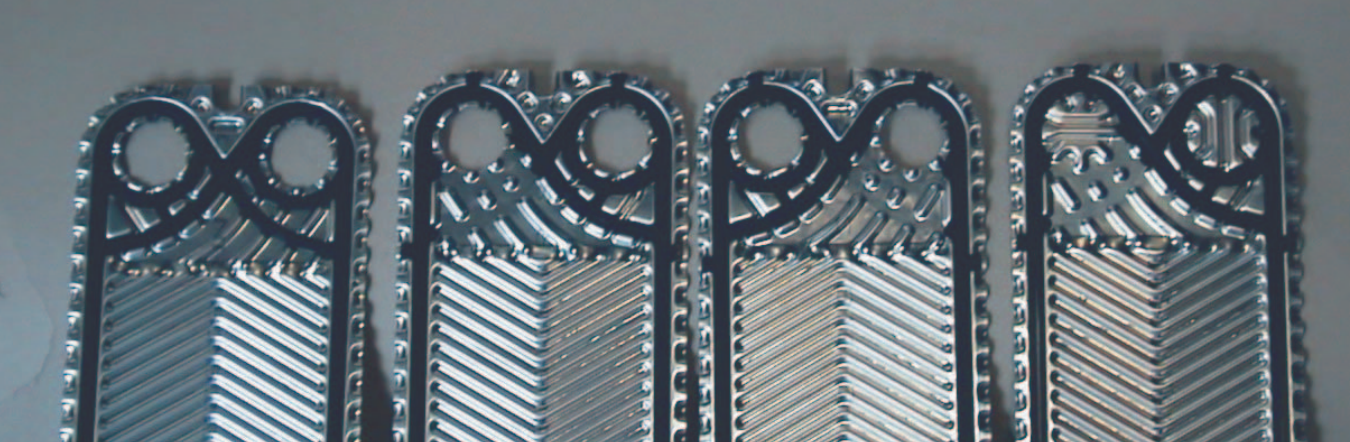

PHE Plate Type

"Start plate with gasket""Left hand flow plate with gasket""Right

hand flow plate with gasket" End plate with gasket"

Thermal Long Plate Thermal Short Plate

M&C Plate Heat Exchanger Service and Maintenance

We can help you avoid problems before they arise with a customized program, ranging from full maintenance support to ad hoc servicing. We will work out the most suitable schedule with you to carry out performance diagnostics, plate cheaning and inspections, fault checking with quick replacements, and repairs as required.

Our skilled technicians will swiftly dismantle your heat exchangers and expertly clean each plate using economic, environmentally - friendly methods. We will have your installation up and running at full capacity again in no time. We are fully equipped to perform CIP(Cleaning in Place) where possible.

If your plate heat exchanger is faulty or under-performing, our repair services will restore your installation to working order in an instant. We substitute defective or worn gaskets, as well as damaged or leaking plates, with originals or high-quality replacements that perfectly match the specifications of your installation.

We can also analyze your current setup to determine if the installation can be optimized, for example by increasing the number of plates in the heat exchanger. This is an upgrade for your entire system, as more efficient heat exchangers improve the overall performance while lowering the energy costs.

Whatever your needs, our dedicated service teams are standing by to help.

Quality Control

Our quality control inspectors meticulously examine the plates for defects. We conduct dye tests to discover potential leaks in the plates, and perform gas tests for ammonia based plate heat exchangers.

Every plate must meet our strict quality demands before being shipped to our customers, to ensure a durable solution with a long lifetime.

We are able to perform diagnostics on-site. If we uncover leaking plates in your current installation, we can replace them with high-performance plates that increase the relability and efficiency of your system.

PHE Problem Solving

If you have problems with your plate type heat exchanger, in most cases these can be solved by your own personnel. Please find below a summary of possible problems as well as possible causes and solutions.

A condition for the continuous proper functioning of your plate type heat exchanger is in strict compliance with the permissible values for pressure and temperature mentioned on the name plate.

Exceeding these values, even as a short-lasting pressure peaks will cause damage to the unit and be the cause of problems.

To avoid costly repairs, we advise you to have the installation work and maintenance carried out by properly trained personnel. You can also contact us.

| Problem | Possible Cause | Possible Solution |

| Leakage | At the connections |

|

| Mixing of primary and secondary circuit |

| |

| In plate package |

| |

| The operating Conditions deviate from the specification |

| |

| Insufficient Capacity | Air in the system |

|

| The operating conditions deviate from the specification |

| |

| The heat exchanger is dirty |

| |

| The connections have been interchanged |

| |

| Too high pressure drop | Flow large the design flow |

|

| Channels in plate(s) blocked |

| |

| Incorrect measurements |

| |

| Medium deviating from the design |

| |

| Air in the system |

|

Plate Heat Exchanger Pictures

M&C Heat Parts Company Profile

M&C Heat Parts Co., Ltd is founded in Wuxi, Jiangsu. M&C is specialized in designing and manufacturing high quality heat transfer equipment. The range of products comprises plates & gaskets, plate heat exchangers, gasketed heat exchangers and brazed heat exchangers. Thus, as one of the few producers worldwide, M&C offers solutions with optimum thermodynamic designs for different industries and virtually all applications.

M&C provide you with one-stop accessories service, multuple-brand & multiple model alternatives for your choice. We'll meet all your requirements of plate heat exchanger and keep your machine running contunously through our rich storage and quick response.

Moreover, we have a strict quality control and after-sales service system, from material purchasing to finished product package until the product received in good condition. Our products have been widely used all over the world in various fields.

M&C Plate Heat Exchanger Plates & Gaskets Other Models Recommend

Sondex/Danfoss - S4A, S7, S20, S21, S22, S41, S43, S47, S65, S81, S86, S100, S120, S130, SFD7, SFD13, SW19 and so on;

APV/SPX - H17, N25, N35, A055, A085, J060, J092, J107, M92, M107, K55, K71, B110, B134, P105, P190, SR1, SR2, TR9GN, TR9AL and so on;

Tranter/Swep - GX12, GL13, GC26, GC51, GX26, GX51, GX42, GX64, GX85, GX91, GX140, GX145 and so on;

API/Schmidt - Sigma 7, Sigma 9, Sigma 13, Sigma 26, Sigma 27, Sigma 36, Sigma 66, Sigma 106, Sigma 229, Sigma Star 45, Sigma Star 90 and so on;

Vicarb - V4, V13, V20, V28, V45, V60, V100, V110, V130 and so on;

Hisaka - EX11, EX15, EX15, LX026, LX195, LX395, LX595, RX135, RX395, RX595, UX115, UX225, UX395, UX495, UX815, UX995 and so on;

GEA - VT04, VT10, VT20, VT40, VT80, VT405, VT805, VT1306, NT50M, NT50X, NT100S, NT150S, NT150L, NT250M, NT250L and so on;

Funke - FP04, FP05, FP14, FP16, FP08, FP22, FP31, FP40, FP41, FP70, FP100, FP120 and so on;

Thermowave - TL200SS/PP, TL250SS/PP, TL400SS/PP. TL650SS/PP and so on;

DHP - DX143, DX146, DX20V, DX20DL, DX20DM, DX30S, DX36M and so on;

LHE - HT101, HT102, HT104, HT151, HT152, HT202, HT232, HT233 and so on;

M&C Plate Heat Exchanger Goods ready to Delivery