Jiangyin M&C Heat Parts Co.,Ltd |

|

Verified Suppliers

|

|

Wide applications gas cooling and condensation plate heat exchanger Funke FP/FPS Series FP10

FP10 Plate Heat Exchanger Introduction

The PHE consists of a pack with linked up embossed plates with passage openings. Every second plate is staggered by 180°, creating a fl ow gap in each case. All plates are provided with gaskets, which completely seal the various fl ow gaps from the outside and separate the second media involved in heat exchange.

The plate pack is mounted in a rack and is pressed between the fi

xed plate and pressure plate by means of clamping bolts.

Warm and cold media are normally led through the PHE in one-pass or

multipass counterfl ows in order to guarantee a maximum heat

transfer.

Connections are on the fi xed plate, in case of multi-pass fl ow

they can also be on the pressure plate.

FP10 Plate Heat Exchanger Gasket And Plate Parameter

| Rubber Type | NBR | EPDM | VITON/FKM | HNBR |

| Application Temperature | -20°C- +130°C | -50°C-+150°C | -30°C-+251°C | -15°C- +160°C |

| Fluid Media | Water Sea water Mineral oil Salt brine | Hot water Steam Acid Alkali | High temperature resistance Strong oxidants Oil Acid and alkali | High temperature mineral oil and water |

| Feature | Easier to replace than the traditional gasket, high pressure, high temperature, longer life, should not be leaked | |||

| Material of Plate | Suited liquid Kinds | |

| Stainless Steel(SUS304,316 etc) | Pure Water,Normal Water,Mineral Oil etc | |

| Ti,Ti-pd | Sea water,Saline water,Mineral water etc | |

| 20Cr,18Ni 6Mo(254SMO) | Dilute Sulphuric Acid,Organic water solution etc | |

| Ni | High-temp and concentration caustic soda | |

| Hastelloy alloy(C276,D205,B2G) | Concentrated sulfuric acid,Hydrochloric acid,Phosphoric acid | |

| Thickness of plate | 0.5mm/0.6mm/0.7mm/0.8mm/0.9mm/1.0mm | |

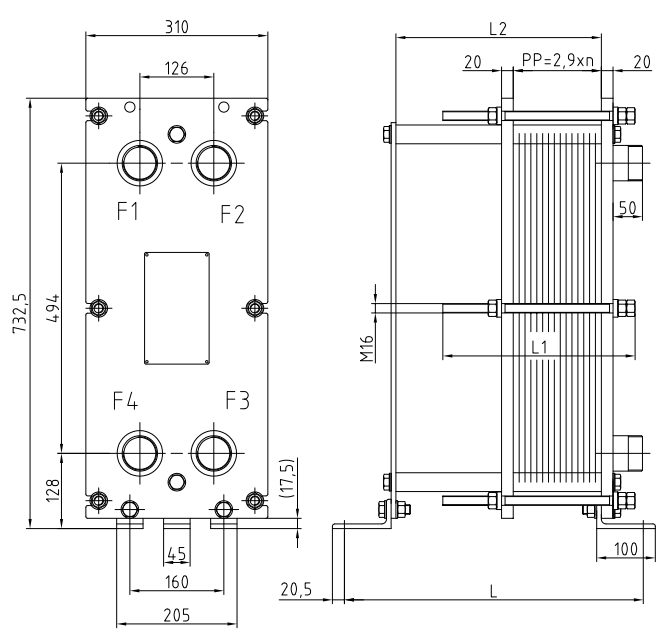

| Plate Shape Size | 598*230mm | |

| Plate Center Size | 494*126mm | |

| Transfer Area | 0.1㎡ | |

| Corrugate Thickness | 2.34mm | |

| Frame Diameter | DN25-500 | |

| Working Pressure | <= 25 bar | |

| Plate Theta | Low Theta and High Theta | |

| Plate Hole | Channel Plate with 4 Holes, End Plate without holes | |

FP10 Plate Heat Exchanger Advantage

| Compact design | High thermal efficiency |

| De-mountable for cleaning and maintenance | Can have additional heat transfer plates added if required |

| Suitable for hygienic and industrial applications | Suitable for use with steam |

| Food-safe material | CIP system-adaptable |

| Simple cleaning | A quality product |

| Low maintenance costs | Long service life |

| Profile variations for highly effective flow relationships | Special plates for steam condensation |

| Advantageous price/Performance ratio | Friendly service |

| High operational safety | Compactness |

| High effectiveness | Wide-ranging application possibilities |

| Food-proof materials | CIP-able |

| Easy cleaning | Austrian high quality product |

| Low investment, operation and maintenance costs | up to 75% less space required |

| Asymmetrical flow gap available for the most cost-efective solutions | Self-cleaning effect due to highly turbulent flow behaviour |

| Plate surface from 0.05㎡ to 1.5㎡ | Throughput up to 500m³/hr |

| Special plates for steam condensers | Subsequent capacity adjustment |

| High safety with regard to media mixing | Low operating weight/low liquid content |

MC heat transfer plates are always produced in 1.4401/ AISI 316L as this material is generally more corrosion-resistant and more resistant to chloride damage than 1.4301/AISI 304. Depending on the design, titanium is also available in serial production.

As an option, the following additional materials may be used:

• 1.4301/AISI 304 (cost-effective in the case of uncritical media)

• 1.4539/AISI 904L (with high nickel content against stress corrosion cracking, good price/performance ratio in the case of media with a low acid and chloride content)

• 1.4529/254 SMO (higher chloride and acid-resistance than 1.4401/AISI 316L)

• Hastelloy (highly resistant against acids and chlorides, e.g. for concentrated sulphuric acid)

• Titanium ASTM B 265

• Titanium-Palladium (highest material quality, suitable e.g. for chlorides at higher temperatures)

All gaskets are installed twice in the entry and exit area, creating a safety room which is open to the outside.

It prevents the two media from mixing if the gasket leaks. Depending on the design and the type, adhesive or non-adhesive (Clip-System) gaskets may be used.

As sealing materials, we use well-known and tried and tested materials such as

• NBR (nitrile-butadiene rubber): Universal use for aque- ous and unctuous media e. g. water/oil applications

• EPDM (ethylene-propylene rubber): Wide range of applications for many chemical compounds which do not contain mineral oil and grease, and for water- and steam application

• Fluororubber (Viton): Extremely resistant to chemicals and organic solvents as well as sulphuric acid and vegetable oils at high temperatures.

Lifetime partnership – our service for your PHE

The design and the high quality standards of MC plate heat exchangers keep the amount of maintenance work to a minimum, provided that the conditions of use for which the PHE has been designed are adhered to. However, during service life, the gaskets of a PHE are subject to a normal fatigue process.

Depending on the conditions of use, the plate pack can be tightened several times until “PP“-min. is reached. Once the plates are provided with new gaskets, the PHE can return to its full capacity.

Normally, maintenance and servicing can be carried out by adequately trained personnel of the operator. If necessary, contact our local service technicians or service partners who can provide the services specifi ed in the adjacent list.

Our service offers for your PHE

• cleaning service: CIP (Cleaning in Place) or mechanical cleaning on site or chemical cleaning (immersion bath) at the factory

• on request, CIP systems (incl. the required cleaning chemicals) can be provided by MC

• provision of plates with new gaskets: always includes cleaning, optional hair crack test

• spare parts service: supply of original parts throughout the world

• overhaul of complete devices

• subsequent performance optimization: extension of plate pack/modifi cation of plate confi guration.