Xinting Machinery Co., Ltd. |

|

Product Description:

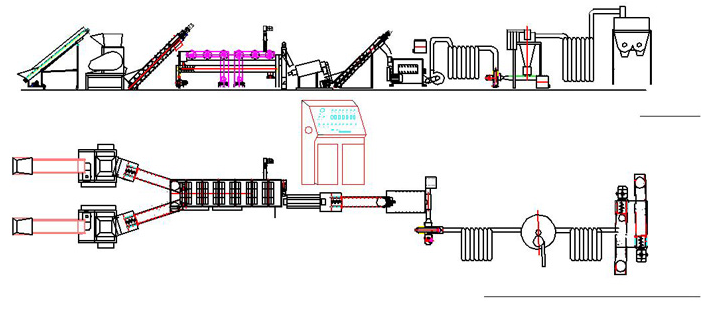

The plastic recycling machine is basically consist of belt conveyer, crusher, steam washer, scrubbing washing unit, rinsing and precipitation washing unit, centrifugal dewatering unit, hot air flow drying unit, and electric control cabinet.

No. | Machine List | Function |

|---|---|---|

| 1 | Belt Conveyor | Bottles conveying |

| 2 | Bottle Label Remover | Remove above 90% labels for both common and compressed bottle; No flakes waste and no water consumption |

| 3 | Manual Sorting Belt | Manually sort out PVC bottle, labels, and other impurities |

| 4 | Belt Conveyor | Bottle conveyor tp crusher |

| 5 | PSJ1200 Crusher | Bottle crushing into flakes |

| 6 | Horizontal Screw Loader | Conveying flakes to next screw loader |

| 7 | Screw Loader | PET flakes conveying |

| 8 | Floating Washer | Wash flakes and remove floating materials as PP, PE and Caustic soda |

| 9 | Low Speed Friction Washer | Remove sand, mud and dirty |

| 10 | Hot Washer | After hot washing, it's easier to remove oil, glue |

| 11 | Screw Loader | PET flakes conveying |

| 12 | Hot Washer | After hot washing, it's easier to remove oil, glue |

| 13 | Screw Loader | PET flakes conveying |

| 14 | High Speed Friction Washer | Remove the glue and dirty |

| 15 | Screw Loader | PET flakes conveying |

| 16&17 | Floating Washer | Wash flakes and remove floating material as PP, PE and Caustic Soda |

| 18 | Spray Washer | Remove the Caustic Soda |

| 19 | Centrifugal Dryer | Drying and flakes moisture reach 2% |

| 20 | Pipeline Dryer | Hot air drying, moisture <1% |

| 21 | Label Flake Separator | Remove little amount of label and dust in PET flakes |

| 22 | Packaging System | Storage silo for PET flakes |

| 23 | Electric Cabinet | Electric control for the complete line, can be customized |

PET Flake Quality Reference Table:

| Moisture Content | <0.9% | Label | <20ppm |

|---|---|---|---|

| PVC | <20ppm | Variegated Tablets | <30ppm |

| Glue | <10ppm | pH | Neutral |

| PP/PE | <20ppm | Total Impurity | <100ppm |

| Metal | <20ppm | Flake Size | 12mm, 14mm or customized |

Production Consumption:

| Items | Average Consumption Per Ton Flakes |

|---|---|

| Electricity (kw/h) | 200 kw/h |

| Steam (kg) | 500 kg |

| Washing Detergent (kg) | 8 kg |

| Water (t) | 2m³ |

Flowchart PET bottle flakes hot water washing line with ss 304 different voltage :

Conveyor belt →Label remover machine → Sorting table→Conveyor belt

→ Crusher → Screw loader→ Float washing tank→ Friction washing

machine → Screw loader→Hot washer tank → High-speed friction

washing machine → Floating washing tank → Dewatering machine → hot

air dryer system → zig zag air classifier system → Silo

click below pic for video.

PP PE HDPE MATERIAL RECYCLING LINE

Waste PE PP film bags recycling(crushing, washing,drying)line

rigid plastics(bottles,barrles,pipes...)

| Model | Capacity(kg/h) | Power consumption (kw) | Water consumption (ton/h) | Manpower | Humidity Content |

| MT-300 | 300kg/hour | 125kw | 3ton/h | 3 | ≤5% |

| MT-500 | 500kg/hour | 260kw | 4-5ton/h | 3 | ≤5% |

| MT-1000 | 1000kg/hour | 395kw | 6ton/h | 4 | ≤5% |

Working flow of PE PP waste recycling washing line

Belt conveyor * 2 → Crusher * 2 → Screw conveyor* 2 → Floating washer → High speed friction machine → Screw conveyor → Dewatering machine → Drying pipe system → Transition storage → Drying pipe system →Storage hopper → Control cabinet

Plastic film squeezer machine, specially designed by our company, this machine can replace the dewatering machine. Compare with dewatering machine, this squeezer machine has advantages as below:

1. low power consumption.

2. low rotation speed, low noise.

3. less space occupy.

4. final products are granules shape, easy to transportation, and easy to feeding on pelletizing line.

Advantages of this PEPP film bags washing line

1. Final products has good quality. When process PP PE film bags,

final products humidity below 5%.

2. The machine with high efficiency, working stable, large

capacity etc.

3. Parts which contact material use SUS304, thickness more than

3mm, ensure long service life time.

4. World famous brand components applied on the production line-

SKF bearing, Siemens contactor, Japan RKC temperature, ABB

invertor, Siemens PLC control.

5. The whole production line with CE certification, ISO9001

certification .