VAINO INTERNATIONAL LIMITED |

|

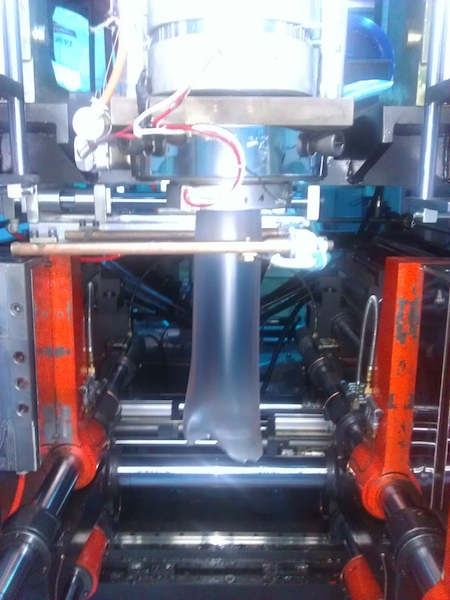

Hydraulic Extrusion Blow Molding Machine 10L chemical tank with automatic deflashing

Brief introduction

Hydraulic system design extusion blow molding machine MP80 is suitable for Producing Medium Size Bottles up to 10L of Various Materials, and Equipped with Single Die Head, Double Die Heads, Three Die Heads, Four Die Heads,Six Die heads.

Adopt four leaders point support structure, it can accept heavy moulds. With parison control system ,it is especially to make bottles below 10 liter ,like toys, auto parts ....

Advantage:

1. most important for a good EBM machine is the action system and the extrusion system.

we'r using powerful hydraulic system design with imported valve and pump for stable action

Adopt China famous brand Gearbox along with Delta extrusion motor ,make sure machine runs continiously,long life.

2. Heavy and stong structure,make sure machine works more faster and stable.

3. Special protection for the machine and people

Sensor in the operating door: if anybody enter the machine,the electricity conneced with the machine will automatic cut down.

Temperature interlock system:When the material inside the barrel is not reaching the setting temperature,the extrusion motor can never start.that will help the screw and head of the machine.

4. Special care for different countries.

we offer some special design for different countries,in order to matching best performance.

5. Easy die head dis-assemble and assemble

6. Defleshing function included

Center distance introduction:

Double head standard Center distance:180mm (160-200mm optional)

Thriple head standard center distance:120mm(100,,125,130mm option)

Four head standard center distance:100mm(90mm as option)

Six head standard center distance:70mm

Machine specification:

| MP80D | ||

| Material | PE,PP,(PVC,PA)OPTION | |

| Max container capacity | L | 10 |

| Number of die | set | 1,2,3,4,6,8 |

| machine Dimension(L×W×H) | M | 3.82×2.54×2.5 |

| Total weight | ton | 4.5 |

| Clamping force | kn | 120 |

| Platen opening stroks | mm | 220-620 |

| Stroke of mould board | mm | 400 |

| Platen size | mm | 420×520 |

| Max mould size(W×H) | mm | 480×500 |

| Mould thinkness | mm | 225-300 |

| Screw diameter | mm | 80 |

| Screw L/D ratio | L/D | 24 |

| Plasticising capacity | kg/h | 85 |

| Number of heating zone | zone | 4 |

| Extruder heating power | kw | 18.5 |

| Power of screw-bar machine | kw | 0.22 |

| Extruder driving power | kw | 30 |

| Number of heating zone | zone | 2 |

| Power of die heating | kw | 13.5 |

| Max die-pin diameter | mm | 180 |

| General power of machine | kw | 73.7 |

| Power of the electric motor of oil pump | kw | 9.5 |

| Air pressure | Mpa | 0.6-0.8 |

| Average energy consumption | kw | 35 |

| Using quantity of compression air | m3/min | 1.5-2.5 |

| Using quantity of cooling water | m3/min | 3.0-5.0 |

Machine parts photo:

This 4 die head blow pin tip,for long narrow neck design bottle.with chiller water tip cooling system

Electric drive hot cutter install on side of the machine for open the parison,best for container with off-center neck