Jinjiang Haina Machinery Co.,Ltd |

|

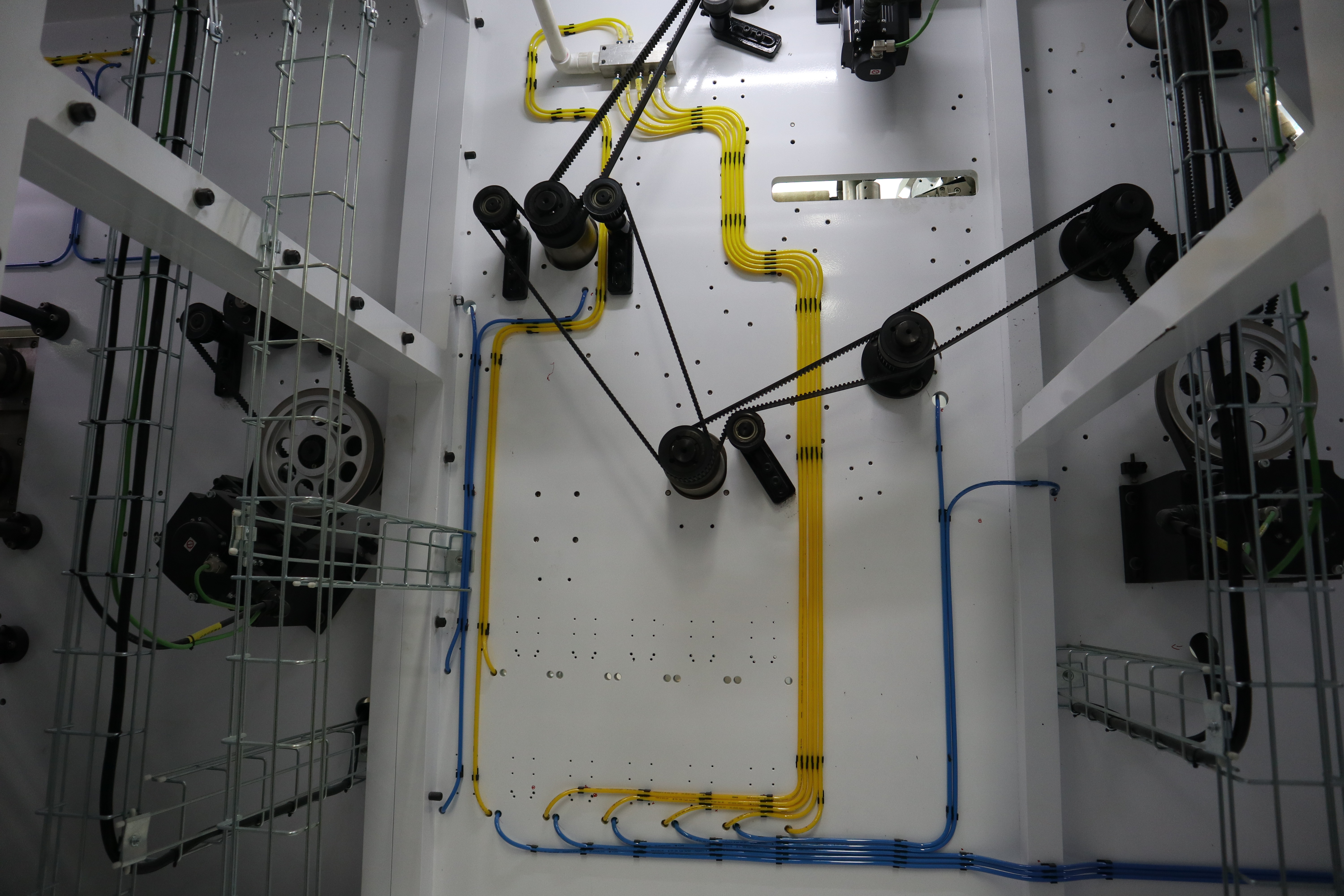

Timing Belt Diaper Machine Spare Parts Gates Brand

1. No slippage during work, with accurate transmission ratio

Synchronous belt transmission is a kind of meshing transmission.

Although the synchronous belt is an elastic body, because the

load-bearing rope in it has the characteristic of not being

stretched under the action of tension, it can keep the belt pitch

constant and make the belt and the wheel cogging. It can mesh

correctly, realize synchronous transmission without slip, and

obtain accurate transmission ratio.

2. High transmission efficiency and good energy saving effect

Since the synchronous belt is used for non-sliding synchronous

transmission, it has a higher transmission efficiency, generally up

to 0.98. Compared with V-belt drive, it has obvious energy saving

effect.

3. Large transmission ratio range and compact structure

The transmission ratio of the synchronous belt transmission can

generally reach about 10, and in the case of a large transmission

ratio, its structure is more compact than the V-belt transmission.

Because the timing belt drive is a meshing drive, the pulley

diameter is much smaller than the V-belt pulley that relies on

friction to transmit power. In addition, because the timing belt

does not require a large tension, the size of the pulley shaft and

the bearing can be adjusted. Decrease. Therefore, compared with the

V-belt drive, the synchronous belt drive has a more compact

structure under the same transmission ratio.

4. Easy maintenance and low operating cost

Since the load-bearing rope in the timing belt is made of glass

fiber, steel wire and other materials with low elongation, the belt

elongation is very small during operation, and there is no need to

adjust the tension force frequently like the V-belt and chain

drive. In addition, the timing belt does not require any

lubrication during operation, so maintenance is very convenient,

and the operating cost is much lower than that of V-belts, chains,

and gears.

5. Can still work under harsh environmental conditions

Although the synchronous belt drive has the above advantages

compared with other drives, it has extremely strict requirements on

the center distance during installation, and at the same time the

manufacturing process is complicated and the manufacturing cost is

high.