GuangYuan Inverter Electronic Equipment Factory |

|

индукционный нагреватель,индукционный водонагреватель ,водонагреватель индукционный ,Индукционный нагревател ,индукционного нагрева станок ,Индукционный нагрев ,Индукционные нагреватели,Индукционное оборудование

High Frequency Portable Induction Heater For Radiator Pipe Brazing

Induction Heater Major Features:

Our High Frequency Inducition Heating Machine adopts the most

advanced MOS,

IGBT frequency conversion control technologies to ensure high

effeiency and maximum

output power.Call us for money-saving,non contact induction heating

equipment for

heating,brazing,annealing,hardening,melting and so on.Benifit from

our induction heating

consultants 15years expersiences creating precision heating

solutions.

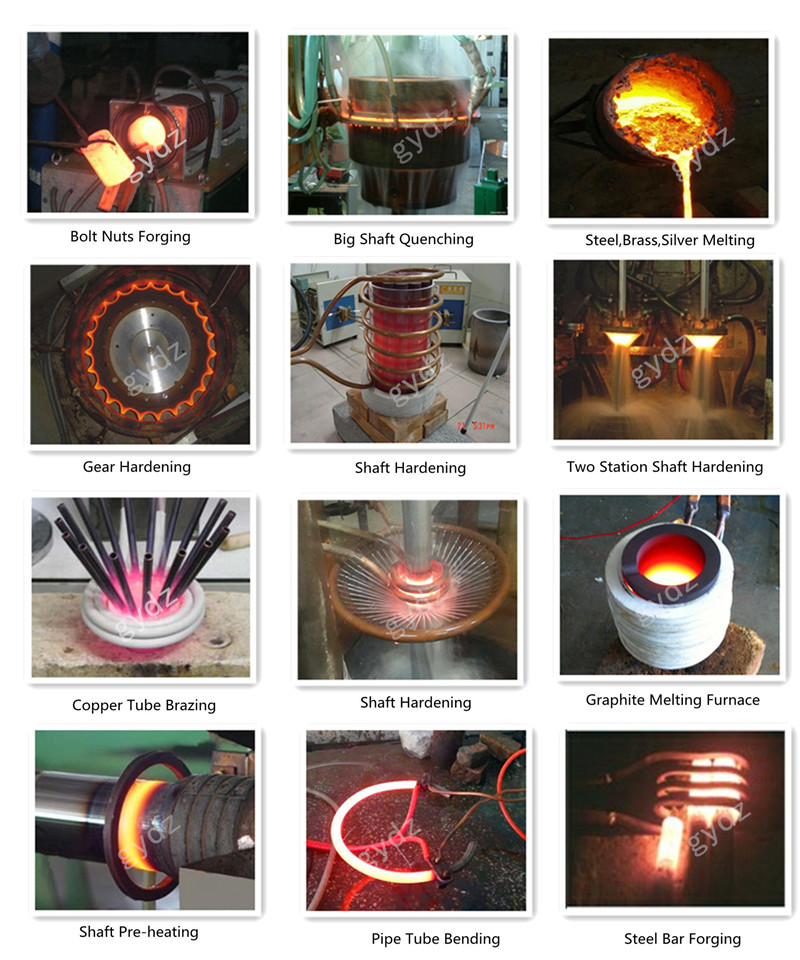

Application of Induction Heater:

A. Heating (hot forging, hot fitting and melting):

B. Heat Treatment (surface quench):

C. Welding (braze welding, silver soldering and brazing)

D. Annealing (tempering and modulation):

Following is induction heater advantage:

A> Fast heating

B> Wide coverage heating

C>Easy installation

D>Easy operation

E>Fast start-up

F>Low power consumption

G>High effectiveness

H>Comprehensive protection

I>Controllable temperature

J>Comprehensive full load design

K>Small size and light weight

L>Elimination of high voltage

Induction Heater 15KW Parameter:

| Model | GY-15A (Single phase) |

| work power | 180V-250V |

| input current | 35A |

| Fluctuating output power | 15KW |

| fluctuating frequency | 30-100KHZ |

| output current | 200-600A |

| the flow rate of cooling water | 0.06-0.12Mpa 7.5L/Min |

| water temperature protection point | 40C |

| product size | 570x230x450mm |

| net weight | 27.5kgs |

Delivery Time: within 3 workdays.

Shipping Term:By sea,By air,by express.

| Model | GY-05A | GY-15A | GY-15AB | GY-25A | GY-25AB | GY-30AB | GY-40AB | GY-60AB | GY-70AB | |

| Work Power | 220V 50HZ Single Phrase | 340V~520V 3Phrase 50~60HZ | ||||||||

| Output Power | 5KW | 15KW | 15KW | 25KW | 25KW | 30KW | 40KW | 60KW | 70KW | |

| Input Current | 32A | 32A | 32A | 24A | 24A | 28A | 41A | 52A | 64A | |

| Output Current | 100~500A | 200~600A | 200~600A | 200~1200A | 200~1200A | 300~1500A | 400~1800A | 400~2400A | 400~3200A | |

| Cooling Water Flow | 0.06-0.12Mpa 7.5L/Min | 0.08-0.16Mpa 7.6L/Min | ||||||||

| Work Frequency | 30~100KHZ | |||||||||

| Timing Setting | 1~99S | |||||||||

| water temperature protection point | 40C | |||||||||

| Dimension | Main Machine | 530x195x450mm | 570x230x450mm | 530x225x450mm | 570x230x510mm | 550x225x480mm | 640x260x520 mm | 620x250x530mm | 640x280x550 mm | 780x370x620 mm |

| Transformer | 370x210x370mm | 350x215x380mm | 440x260x410 mm | 480x260x410 mm | 510x260x410 mm | 870x430x750 mm | ||||

| Weight | Main Machine | 21.5KG | 27.5KG | 18kgs | 31kgs | 21.5 kgs | 26.5 kgs | 34.5kgs | 37.5 kgs | 54 kgs |

| Transformer | 15kgs | 17 kgs | 20.5 kgs | 31.5kgs | 32.5 kgs | 76.5 kgs | ||||

Extra accessories accept choose,

1>Chiller

2>Customer design Coil

3>Infrared Thermometer

4>Back-up Electronic Boards

5>Forging Furnace,Melting Furnace,Hardening Fixture

About service question:

Q: Why choose GuangYuan Company?

A: We are manufacture which had in this filed for nearly 20 years.No matter quality,price,

service,delivery time,we all have large advantage.

Q:How to choose suiteble machine?

A:You can tell us your application,need forging,hardening,welding,melting or other,pass me

workpiece material & size,Temperature requirement and heating time requirement.Then we

will recommend fit machine for you reference.

Q:How about the machine delivery time?

A: Small machine delivery time is 3~7 workdays.Big machine delivery time 15~25 workdays.

Q:How about the machine warranty?

A:Our goods support one year warranty not by personal purpose,support technical service all life.

During the warranty,if machine have problem need change spare parts,we can replace for you

charge free.

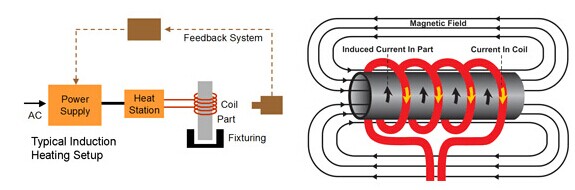

Induction Heater Work Principle: