Weifang Guote Mining Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Product Introduction:

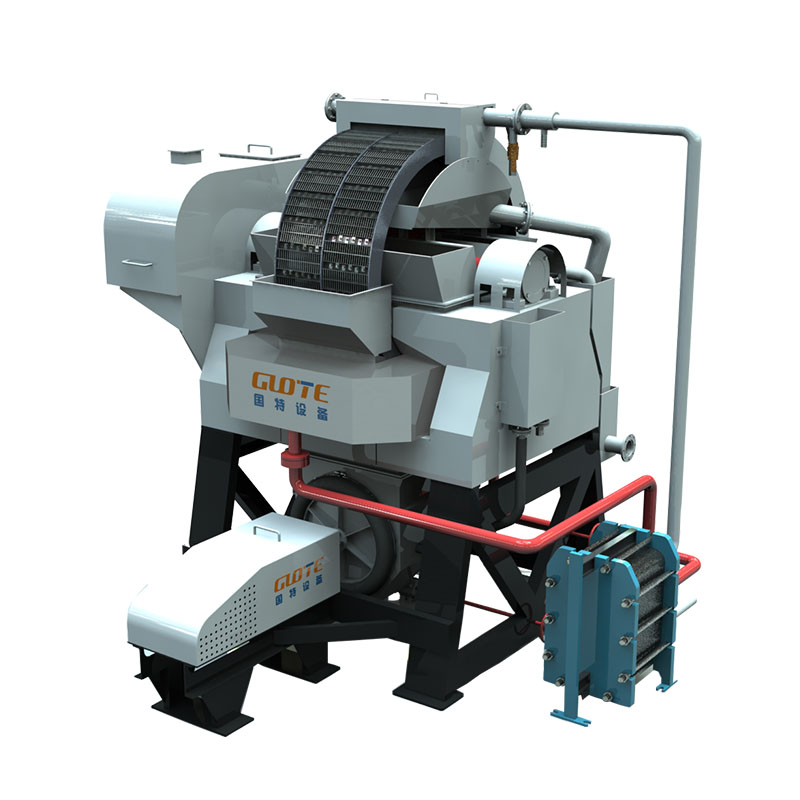

The high intensity magnetic separator with most advanced technology and best performance in the worldwide. Whole equipment have swivel vertical rotation and back flush mineral ores functions, following with high frequency vibration motor. It has higher enrichment ratio and can adapt different particle size and concentration and grade of mineral ores. And also have advantages of reliable working and easy operation and maintenance.

Application scope:

It is suitable for the purification of iron and fine grained red ore (hematite limonite siderite, etc.) in non-metallic ore, such as kaolinite

Advantages:

1,Vertical Swivel with High separation efficiency: Vertical

Swivel rotation and back flush mineral ores make the flat ring jam

problem shooting.

2,Unique magnetic medium with high magnetic intensity: the

company patented magnetic medium could offer high gradient magnetic

field with max. Magnetic intensity up to 20000Gs.

3,Good cooling effect with stable magnetic field. The

excitation coil adapt hollow tube with higher thickness. The water

could flow through tube and take away the heat after water

circulation.

4,Widely used for different field and no need

maintenance.

Technical parameter:

| Model | GTLH-500 | GTLH -750(Z) | GTLH -1000 (Z) | GTLH -1250 (Z) | GTLH -1500 (Z) | GTLH -1750 (Z) | GTLH -2000 (Z) | GTLH -2500 (Z) | GTLH -3000 (Z) |

| Rated background magnetic field(T) | 1(0.6)Constant current continuously adjustable | ||||||||

| Magnetic field | 1.9(1.2)Constant current continuously adjustable | ||||||||

| Energizing power(KW) | ≤10(6) | ≤13(8) | ≤17(10) | ≤19(12) | ≤27(15.5) | ≤37(23) | ≤42(29) | ≤57(37) | ≤74(48) |

| Handing capacity(t/h) | 0.1-0.3 | 0.1-0.5 | 3.5-7.5 | 10-20 | 20-30 | 30-50 | 50-80 | 80-150 | 150-250 |

| Slurry throughput(m3/h) | 0.25-0.5 | 5-10 | 12.5-20 | 20-50 | 50-100 | 75-150 | 100-200 | 200-400 | 360-650 |

| Magnetizing current(A) | 63 | 72 | 85 | 92 | 105 | 124 | 130 | 153 | 185 |

| Slurry density(%) | 10-40 | ||||||||

| Feed particle size | -1.0 | -1.0 | -1.2 | -1.2 | -1.2 | -1.2 | -1.2 | -1.2 | -1.2 |

Ring speed (r/min) | 3 | ||||||||

| Ring diameter(mm) | Φ500 | Φ750 | Φ1000 | Φ1250 | Φ1500 | Φ1750 | Φ2000 | Φ2500 | Φ3000 |

| Ring motor power(KW) | 0.37 | 0.75 | 1.1 | 1.5 | 3 | 4 | 5.5 | 11 | 18.5 |

| Ripply motor power(KW) | 0.37 | 1.5 | 2.2 | 3 | 3 | 4 | 7.5 | 11 | 18.5 |

| Pulsion stroke(mm) | 0-30(Mechanically adjustable) | ||||||||

| Pulsion frequency | 0-300(Variable frequency conversion) | ||||||||

| Excitation voltage(DCV) | 0-409(280)(Change with current) | ||||||||

| Unloading water pressure(Mpa) | 0.1-0.2 | 0.1-0.2 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 | 0.2-0.5 | 0.2-0.4 | 0.2-0.4 | 0.2-0.4 |

| Water supply pressure(m3/h) | 0.65-1.4 | 1.4-2.5 | 8-12 | 12-20 | 20-30 | 30-50 | 50-100 | 100-150 | 150-250 |

| Host weight(t) | 3(1.5) | 5(3.5) | 9(7) | 14(11) | 24(20) | 35(28) | 50(39) | 105(83) | 150(135) |

| Maximum part weight(t) | 0.3(0.25) | 0.6(0.5) | 2.2(2) | 4(3.5) | 5(5) | 11(9) | 16(13) | 23(18) | 24(19) |

| Dimensions(mm) | 1800* 1400* 1320 | 2000* 1360* 1680 | 2700* 2000* 2400 | 3200* 2340* 2700 | 3600* 2900* 3200 | 3900* 3300* 3800 | 4200* 3650* 4200 | 5800* 6000* 5400 | 7600* 6500* 7200 |

Working principle:

Pulp through the feeding tube into the feed hopper, pulp along the magnetic gap through the swivel,

high permeability of the stainless steel rods inside the ring of the magnetic induction medium magnetized in the background magnetic field, form a high gradient magnetic field, magnetic medium pulp in the magnetic particles are adsorbed on the surface of magnetic medium,

the swivel rotation was taken to to the top of the magnetic field area, by flushing with rinse water pressure, the magnetic materials into concentrate in the bucket, non-magnetic particles along the magnetic gap into the tailings under drained bucket in order to realize the separation of material

Swivel lower magnetic medium of submerged within the ore slurry surface,

at the same time of slurry injection, installed at the side of the tailings boxes of reciprocating motion stroke box constantly doing, make through tympanic membrane separation indoor pulp do fluctuate,

the pulsating flow physical ore grain group always maintain loose state in the process of sorting, effectively remove the particles in material, significantly improve the grade of concentrate

Related Peoducts Links

| ||

| permanent magnetic type | ||

| CTB(N/S) wet magnetic separator | GCT/F dry magnetic separator | GCX dry magnetic separator |

| ||

| electronmagnetic type | ||

| GDF dry electromagnetic separator | GTLH wet electromagnetic separator | GTDZ electromagnetic separator for slurry |

Certification

Our customers :

1.EPC service for single equipment and whole production line.

2.OEM service for your personal equipment or production line

3.Testing before delivery and Pretesting in working site until get qualified products

4.24hours for technical Operation Guide and 4hours offer technical proposal for problem shooting.

Q: Why we believe in Weifang GuoteMining Equipment Company?

A: 1. More than 10 years experience.

Q. We are the leading professional supplier of mining equipments

and service for quartz mining equipment industry.

A. All products achieved ISO9001:2000 quality management

certificate and EU CE certificate.

Q: Delivery time

A: The lead time is 10-30 days, delivery time will vary depending

on the type of the machine, shipping method selected and part

availability.

Q: Payment terms

A: Accepted Payment Type: T/T, L/C, Western Union, Cash.

After sign the contract, pay the 30% deposit of total purchase

price and pay the full payment before delivery.

Q: What will you do if the machine is broken down?

A: The Products warranty is one year. We will provide the technical

advice and find the solution immediately for you when the

machine is in trouble. For those wear parts, we guarantee the high

quality parts for long-term supply.

Q: What should I do if I want to get a best quotation?

A: If you want a suitable type for you, please let us know

your material and capacity.